High-elasticity conductive fiber and preparation method thereof

A conductive fiber, highly elastic technology, applied in the direction of fiber type, fiber treatment, textile and paper making, etc., to achieve good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

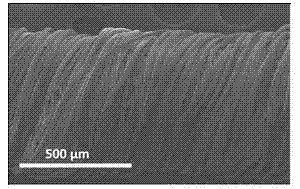

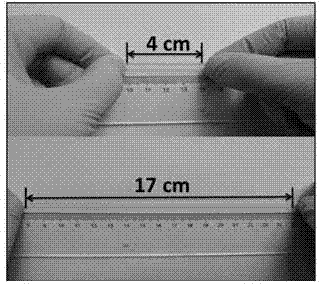

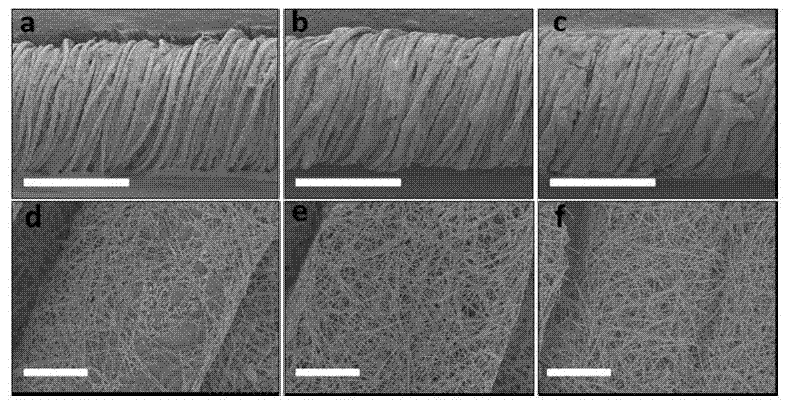

[0073] The preparation method of the ultra-high elastic conductive fiber in the present invention is as follows: metal nanowires (copper nanowires or silver nanowires) are dispersed in an ethanol solution containing PVP or cetylamine to form a high-concentration dispersion with a concentration of 1-20mg / ml. Soak the pretreated cotton spandex fiber (diameter ~600μm) in the metal nanowire dispersion for 5 seconds and take it out. After drying, continue to repeat the same operation to improve the metal nanowire on the surface of the composite fiber. content, after the coating of metal nanowires is completed, the elastic composite fiber is treated with hydrogen plasma, and finally the method of in-situ polymerization and curing is adopted. The elastic composite fiber is immersed in liquid PDMS for 3 seconds and then taken out. Under heating for 2-10 hours for polymerization and curing, the preparation process is completed.

[0074] The invention also provides a highly elastic co...

Embodiment 1

[0084] After cleaning the cotton spandex double-covered yarn, use oxygen plasma treatment (100W, 10min), and then dip and coat in the silver nanowire ethanol dispersion (adding a small amount of PVP) with a concentration of 20mg / ml for 2 times, each dipping time 3 seconds, then use hydrogen plasma treatment (100W, 10min), and finally soak in liquid PDMS for 5s, then take it out for thermal polymerization and curing (80°C, 4h), that is, the preparation process is completed, and the prepared elastic fiber has a conductivity of 100S / cm .

Embodiment 2

[0086] Cotton spandex double-covered yarn is cleaned and treated with oxygen plasma (200W, 5min), and then dipped and coated 10 times in the silver nanowire ethanol dispersion (adding a small amount of PVP) with a concentration of 20mg / ml. 3 seconds, then use hydrogen plasma treatment (200W, 5min), and finally soak in liquid PDMS for 5s, then take it out for thermal polymerization and curing (100°C, 2h), that is, the preparation process is completed, and the electrical conductivity of the prepared elastic fiber is 750S / cm .

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com