A kind of polyurethane coating fabric and preparation method thereof

A polyurethane coating and fabric technology, which is applied in the field of polyester modification, can solve problems such as cost increase and complicated dipping process, and achieve the effect of improving use efficiency and good interface bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

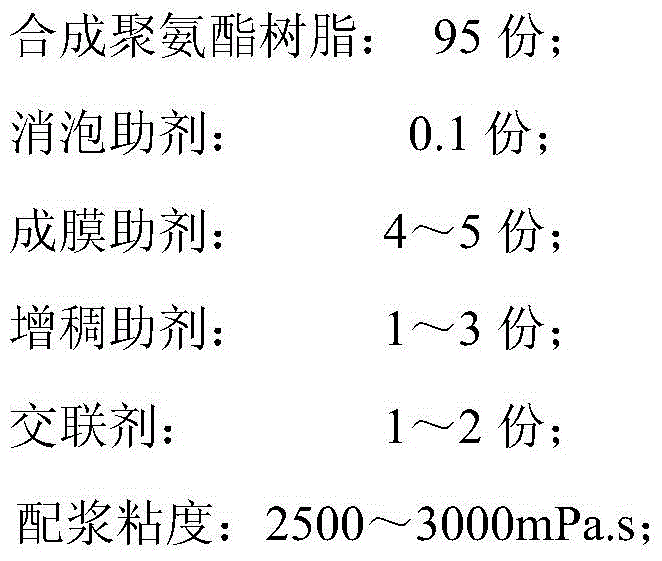

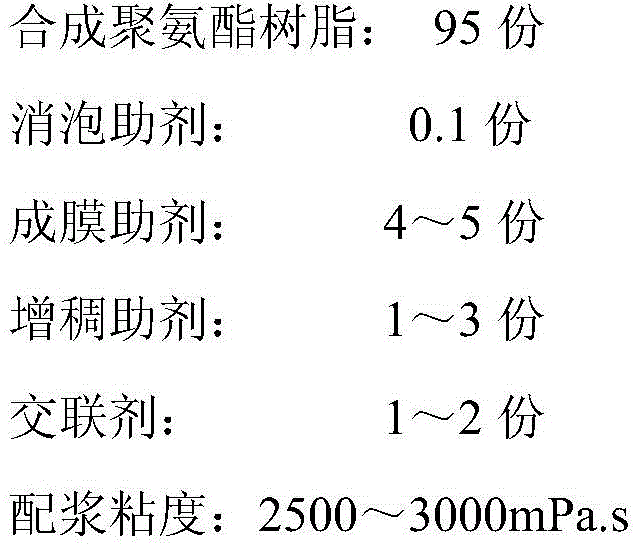

[0088] A preparation method of polyurethane coated fabric, comprising the following steps:

[0089] (1) Preparation of amino fatty acid ethylene glycol ester:

[0090] 1) Add dodecanedicarboxylic acid and methanol into the reactor at a molar ratio of 1:1.5, heat to 80°C under the catalysis of concentrated sulfuric acid, reflux for esterification, cool, separate and purify to obtain dodecanedicarboxylic acid Acid monomethyl ester; Described concentrated sulfuric acid refers to the sulfuric acid that mass concentration is 70%, and the concentrated sulfuric acid add-on is 3wt% of dodecane dicarboxylic acid;

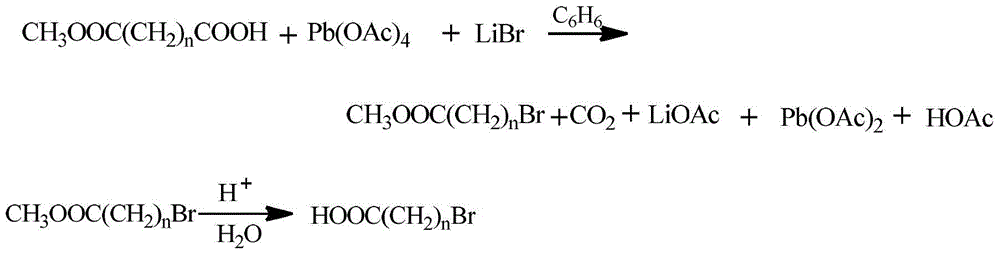

[0091] 2) Dissolve the monomethyl dodecanedicarboxylate, lead tetraacetate and lithium bromide in benzene (molar ratio 1:1:1), wherein the monomethyl dodecanedicarboxylate concentration is 0.05mol / L , under a nitrogen atmosphere, react at 80 ° C, reflux, when no more gas is produced, add a certain amount of dilute sulfuric acid to react for 2 hours, then wash, purify and dry ...

Embodiment 2

[0129] A preparation method of polyurethane coated fabric, comprising the following steps:

[0130] (1) Preparation of amino fatty acid ethylene glycol ester:

[0131] 1) Add pentacodecanedicarboxylic acid and methanol into the reactor in a molar ratio of 1:1.5, under the catalysis of concentrated sulfuric acid, heat to 110°C, reflux for esterification, cool, separate and purify to obtain pentacodecane Dicarboxylic acid monomethyl ester; Described concentrated sulfuric acid refers to the sulfuric acid that mass concentration is 70%, and the concentrated sulfuric acid add-on is 3wt% of pentacosane dicarboxylic acid;

[0132] 2) The monomethyl pentacodecanedicarboxylate, lead tetraacetate and lithium bromide are dissolved in benzene (molar ratio 1:1:1), wherein the concentration of monomethyl pentacodecanedicarboxylate is 0.07mol / L, under nitrogen atmosphere, react at 85°C, reflux, when no more gas is generated, add a certain amount of dilute sulfuric acid to react for 3 hours...

Embodiment 3

[0170] A preparation method of polyurethane coated fabric, comprising the following steps:

[0171] (1) Preparation of amino fatty acid ethylene glycol ester:

[0172] 1) Add pentadecanedicarboxylic acid and methanol into the reactor in a molar ratio of 1:1.5, under the catalysis of concentrated sulfuric acid, heat to 85°C, reflux for esterification, cool, separate and purify to obtain pentadecanedicarboxylic acid acid monomethyl ester; described concentrated sulfuric acid refers to the sulfuric acid that mass concentration is 70%, and the concentrated sulfuric acid add-on is 3wt% of pentadecanedicarboxylic acid;

[0173] 2) Dissolve the monomethyl pentadecanedicarboxylate, lead tetraacetate and lithium bromide in benzene (molar ratio 1:1:1), wherein the concentration of monomethyl pentadecanedicarboxylate is 0.08mol / L , under nitrogen atmosphere, react at 90°C, reflux, when no more gas is produced, add a certain amount of dilute sulfuric acid to react for 2.5 hours, then was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water pressure | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com