Preparation method of silicon carbide film

A silicon carbide and thin-film technology, applied in chemical instruments and methods, catalyst carriers, gaseous chemical plating, etc., can solve the problems of single surface morphology, low specific surface area, low efficiency, etc., to increase catalytic efficiency and service life , the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

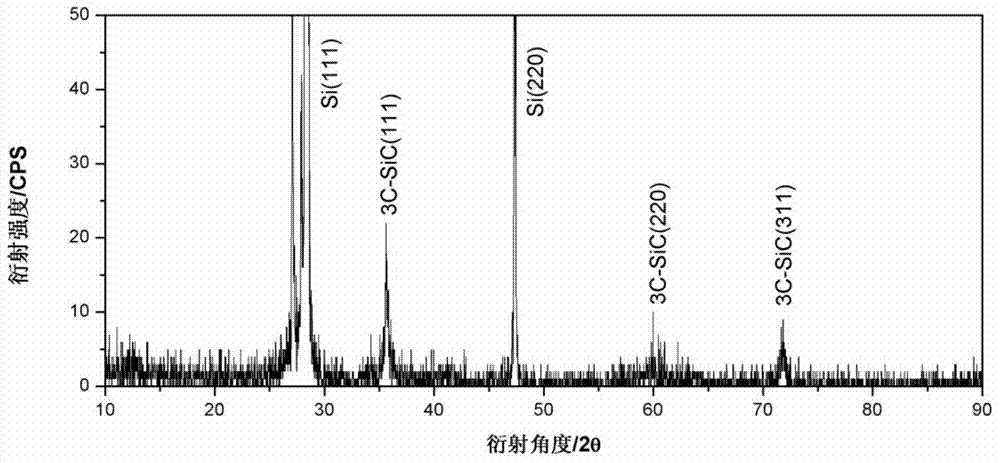

[0020] Such as figure 1 Shown, a kind of preparation method of silicon carbide film comprises the steps:

[0021] (1) The substrate is first placed in ethanol for ultrasonic treatment, then placed in a mixed solution of ammonia water and hydrogen peroxide for cleaning, then soaked in hydrofluoric acid aqueous solution, and then washed with deionized water;

[0022] (2) Put the cleaned monocrystalline silicon substrate on the substrate seat of the cold-wall laser chemical vapor deposition device, and vacuumize to reduce the pressure to 3Pa;

[0023] (3) Administer an appropriate amount of argon;

[0024] (4) Turn on the laser to irradiate the surface of the silicon substrate, the laser wavelength is 1050 nm, and wait until the temperature of the substrate rises to 1200 °C and remains stable;

[0025] (5) Open the carrier gas containing HMDS so that the flow rate of HMDS is 8×10 -5 Moles per minute, and adjust the vacuum degree of the reaction chamber to 1000Pa for 10 minutes...

Embodiment 2

[0029] A method for preparing a silicon carbide film comprises the following steps

[0030] (1) The substrate is first placed in ethanol for ultrasonic treatment, then placed in a mixed solution of ammonia water and hydrogen peroxide for cleaning, then soaked in hydrofluoric acid aqueous solution, and then washed with deionized water;

[0031] (2) Put the cleaned monocrystalline silicon substrate on the substrate seat of the cold-wall laser chemical vapor deposition device, and vacuumize to reduce the pressure to 3Pa;

[0032] (3) Administer an appropriate amount of argon;

[0033] (4) Turn on the laser to irradiate the surface of the silicon substrate, the laser wavelength is 1050 nm, and wait for the temperature of the substrate to rise to 1300 °C and keep it stable;

[0034] (5) Open the carrier gas containing HMDS so that the flow rate of HMDS is 1×10 -4 Moles per minute, and adjust the vacuum degree of the reaction chamber to 500Pa for 10 minutes;

[0035] (6) Turn off...

Embodiment 3

[0038] A method for preparing a silicon carbide film comprises the following steps

[0039] (1) The substrate is first placed in ethanol for ultrasonic treatment, then placed in a mixed solution of ammonia water and hydrogen peroxide for cleaning, then placed in hydrofluoric acid aqueous solution for ultrasonic cleaning, and then washed with deionized water;

[0040] (2) Put the cleaned monocrystalline silicon substrate on the substrate holder of the cold-wall laser chemical vapor deposition device, and vacuumize to reduce the pressure to below 3Pa;

[0041] (3) Administer an appropriate amount of argon;

[0042] (4) Turn on the laser to irradiate the surface of the silicon substrate, the laser wavelength is 1050 nm, and wait until the temperature of the substrate rises to 1380 °C and remains stable;

[0043] (5) Open the carrier gas containing HMDS so that the flow rate of HMDS is 4×10 -4 Moles per minute, and adjust the vacuum degree of the reaction chamber to 200Pa for 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com