Protective material for joint coating of outer erosion resistant layer of pipeline

A technology of protective materials and anti-corrosion layers, which is applied in the field of pipeline systems, can solve problems that affect the progress of crossing construction, the time of protective treatment should not be too long, and affect the progress of construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

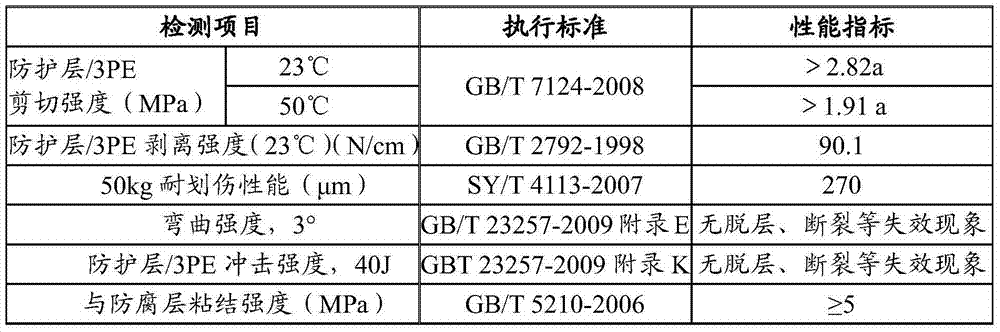

Examples

Embodiment 1

[0052] This embodiment provides a protective material for sealing the outer anticorrosion layer of a pipeline, which includes a protective layer covering the outside of the pipeline and a putty system at both ends of the protective layer. The protective layer includes a resin system and a fiber reinforcement. The resin system includes the following components in mass percent: E51 epoxy resin 55%, polyetheramine D2000 10%, polythiol 30%, 2,4,6-tris(dimethylaminomethyl)phenol accelerator 2 %, polypropylene oxide butyl ether reactive diluent 3%. The fiber reinforcement is 200g / m 2UHMWPE fiber unidirectional cloth. The putty system includes the following components in mass percent: E51 epoxy resin 45%, polyetheramine D2000 15%, polythiol 20%, 2,4,6-tris(dimethylaminomethyl)phenol accelerator 1%, polypropylene oxide butyl ether reactive diluent 3%; silane coupling agent KH550 1%; toughening agent CYH-277 5%; glass microspheres 10%.

Embodiment 2

[0054] This embodiment provides a protective material for sealing the outer anticorrosion layer of a pipeline, which includes a protective layer covering the outside of the pipeline and a putty system at both ends of the protective layer. The protective layer includes a resin system and a fiber reinforcement. The resin system includes the following components in mass percent: E51 epoxy resin 57%, polyetheramine D2000 13%, polythiol 25%, 2,4,6-tris(dimethylaminomethyl)phenol accelerator 1%, Polypropylene oxide butyl ether reactive diluent 4%. The fiber reinforcement is 200g / m 2 Fiberglass satin. The putty system includes the following components in mass percent: E51 epoxy resin 48%, polyetheramine D2000 12%, polythiol 15%, 2,4,6-tris(dimethylaminomethyl)phenol accelerator 2%, polypropylene oxide butyl ether reactive diluent 5%; silane coupling agent KH550 2%; toughening agent CYH-277 2%; glass microspheres 14%.

Embodiment 3

[0056] This embodiment provides a protective material for sealing the outer anticorrosion layer of a pipeline, which includes a protective layer covering the outside of the pipeline and a putty system at both ends of the protective layer. The protective layer includes a resin system and a fiber reinforcement. The resin system includes the following components in mass percent: E51 epoxy resin 60%, polyetheramine D2000 12%, polythiol 20%, 2,4,6-tris(dimethylaminomethyl)phenol accelerator 1%, polypropylene oxide butyl ether reactive diluent 7%. The fiber reinforcement is 200g / m 2 Basalt fiber non-woven fabric. The putty system includes the following components in mass percent: E51 epoxy resin 50%, polyetheramine D2000 10%, polythiol 15%, 2,4,6-tris(dimethylaminomethyl)phenol accelerator 1%, polypropylene oxide butyl ether reactive diluent 3%; silane coupling agent KH550 1%; toughening agent CYH-277 2%; glass microspheres 18%.

[0057] The specific preparation and construction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com