Preparing method of counter electrode for dye-sensitized solar cell

A solar cell and dye sensitization technology, which is applied in the field of dye sensitized solar cell materials, can solve the problems of easy reduction in activity and easy poisoning, and achieve the effects of reducing catalyst poisoning, easy implementation, and improving electrocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

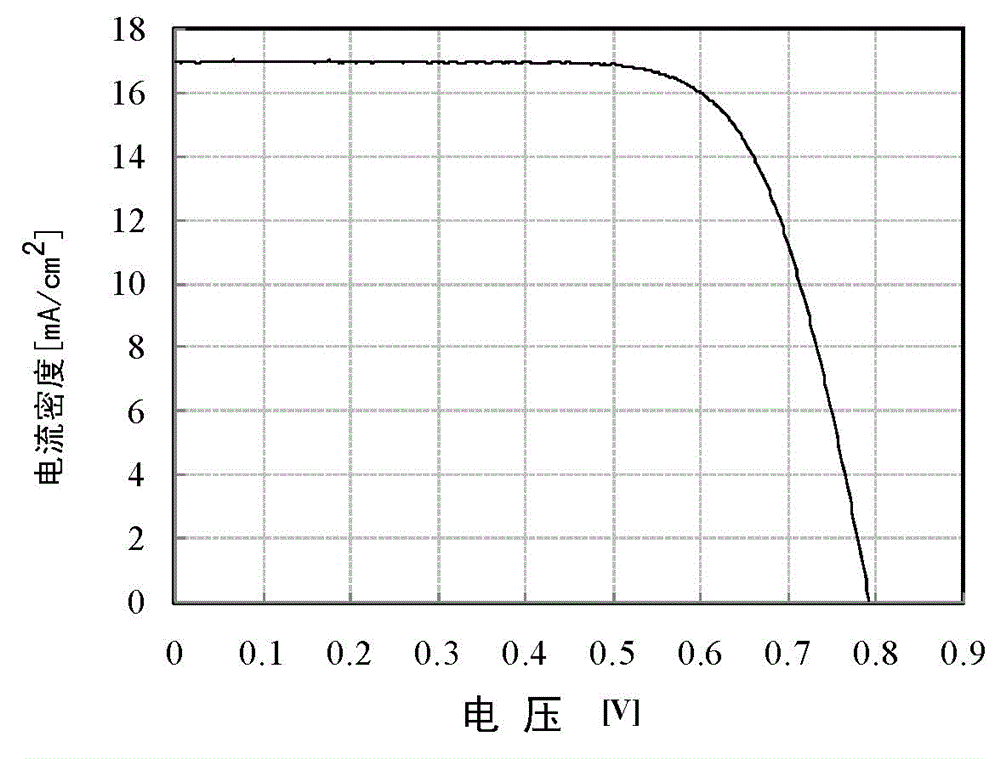

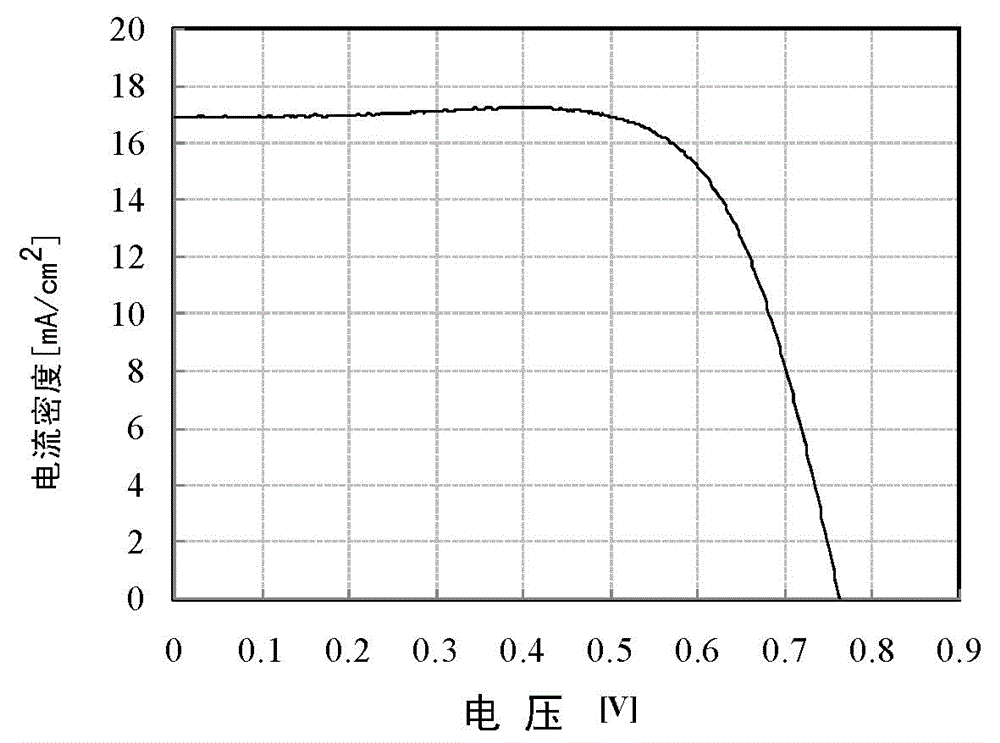

Examples

preparation example Construction

[0032] In order to solve the problem of catalyst poisoning in the counter electrode in the above production process, the present invention provides a method for preparing a counter electrode for a dye-sensitized solar cell, which can remove pollutants remaining in the pore structure of the counter electrode or adsorbed on the surface of the catalyst, Avoiding or alleviating catalyst poisoning in CE, and then preparing dye-sensitized solar cells with high photoelectric conversion performance, the technical solution of the invention is easy to implement, and provides a new idea for the preparation of counter electrodes for dye-sensitized solar cells.

[0033] The invention provides a method for preparing a counter electrode for a dye-sensitized solar cell (DSSC). The experimental steps of the preparation method of the counter electrode include ① preparing an electrocatalytic active material film on the counter electrode substrate, and ② performing activation treatment on the coun...

Embodiment 1

[0062] (1) Preparation of the slurry of the electrocatalytic material:

[0063] Mix 20g of carbon fiber, 5g of carbon nanohorn powder, 5g of vanadium nitride powder and 5g of vanadium sulfide powder, then add 15g of titanium dioxide powder with a particle size of 30nm, and 20g of ethyl cellulose, mix properly, and then add 100g of N-methyl- -Pyrrolidone (NMP), centrifugally mixed for 30min, then ball milled for 12h to prepare the slurry of the electrocatalytic material;

[0064] (2) Preparation of conductive substrate (ITO):

[0065] Clean the ITO board with deionized water and acetone ultrasonically for 25 minutes respectively, dry the ITO board after ultrasonic cleaning, and set aside;

[0066] (3) Slurry coating of electrocatalytic materials:

[0067] Coat low-cost electrocatalytic material slurry on the cleaned ITO substrate by screen printing method, dry at 100°C for 5 minutes, and then treat at 150°C for 15 minutes under the protection of inert gas;

[0068] (4) UV-oz...

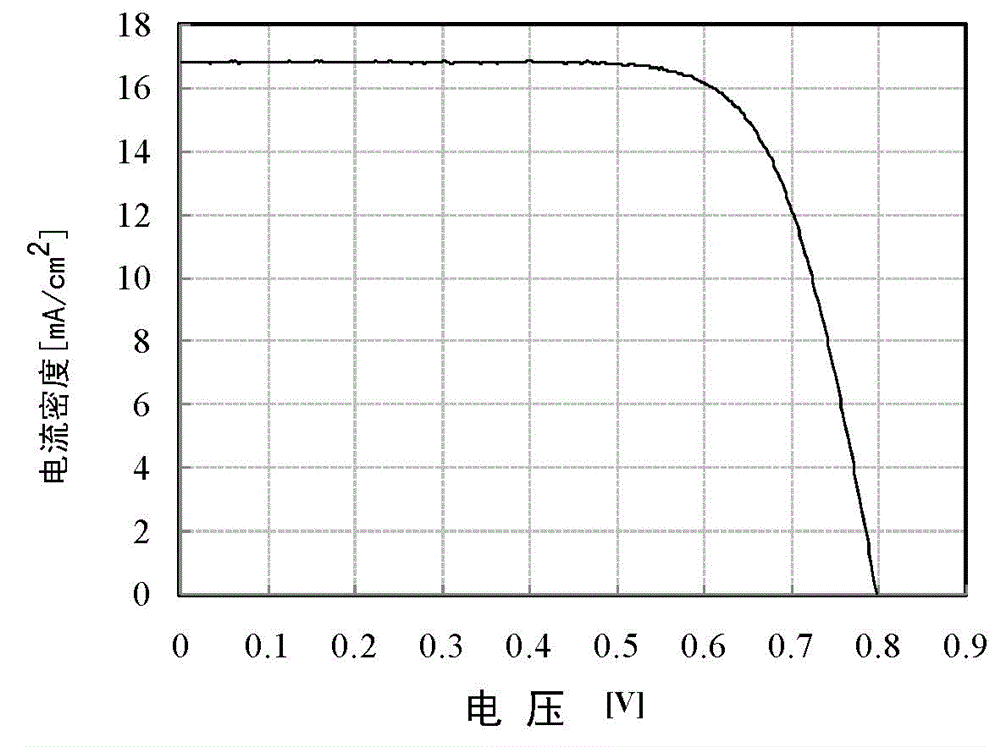

Embodiment 2

[0071] (1) Preparation of the slurry of the electrocatalytic material:

[0072] Mix 20g carbon fiber, 5g pigment carbon black powder, 5g tantalum carbide powder and 5g tungsten phosphide powder, then add 15g titanium dioxide powder with a particle size of 200nm, and 30g ethyl cellulose, after proper mixing, add 300g terpineol, high Shearing and mixing for 30 minutes, and ball milling and mixing for 5 hours to prepare the slurry of the electrocatalytic material;

[0073] (2) Preparation of conductive substrate (Ti plate):

[0074] Clean the Ti plate with deionized water and acetone ultrasonically for 25 minutes respectively, dry the Ti plate after ultrasonic cleaning, and set aside;

[0075] (3) Slurry coating of electrocatalytic materials:

[0076] Coat low-cost electrocatalytic material slurry on the cleaned Ti substrate by spin coating method, dry at 100°C for 5 minutes, and then treat at 450°C for 30 minutes;

[0077] (4) UV activation treatment of the electrode:

[007...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com