An oil shale gas heat carrier carbonization furnace that is easy to be enlarged

A technology of gas heat carrier and carbonization furnace, which is applied in the field of oil shale carbonization furnace, can solve the problems of insufficient material utilization efficiency, low calorific value of outlet gas, and environmental pollution, so as to solve the problems of coking and incomplete carbonization, and improve output The effect of improving the oil rate and improving the efficiency of dry distillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following structural drawings and embodiments further describe the present invention:

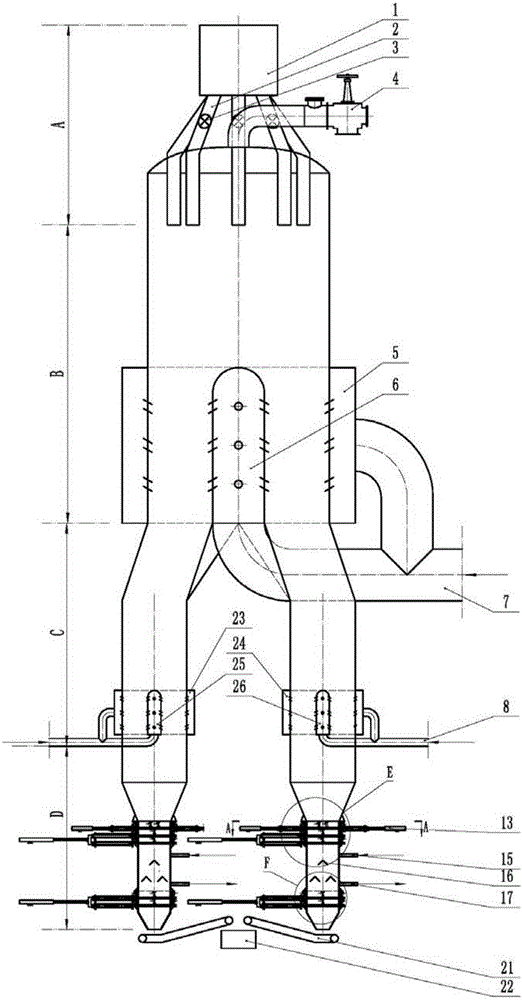

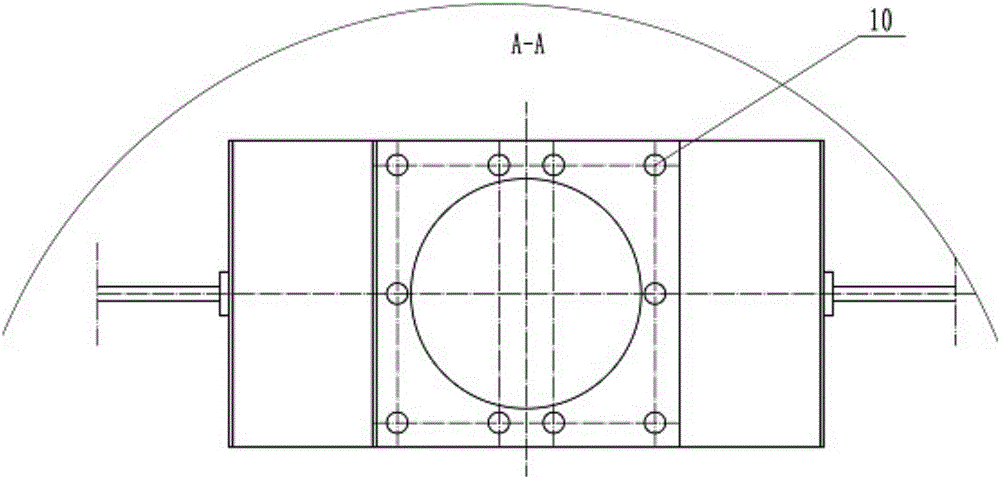

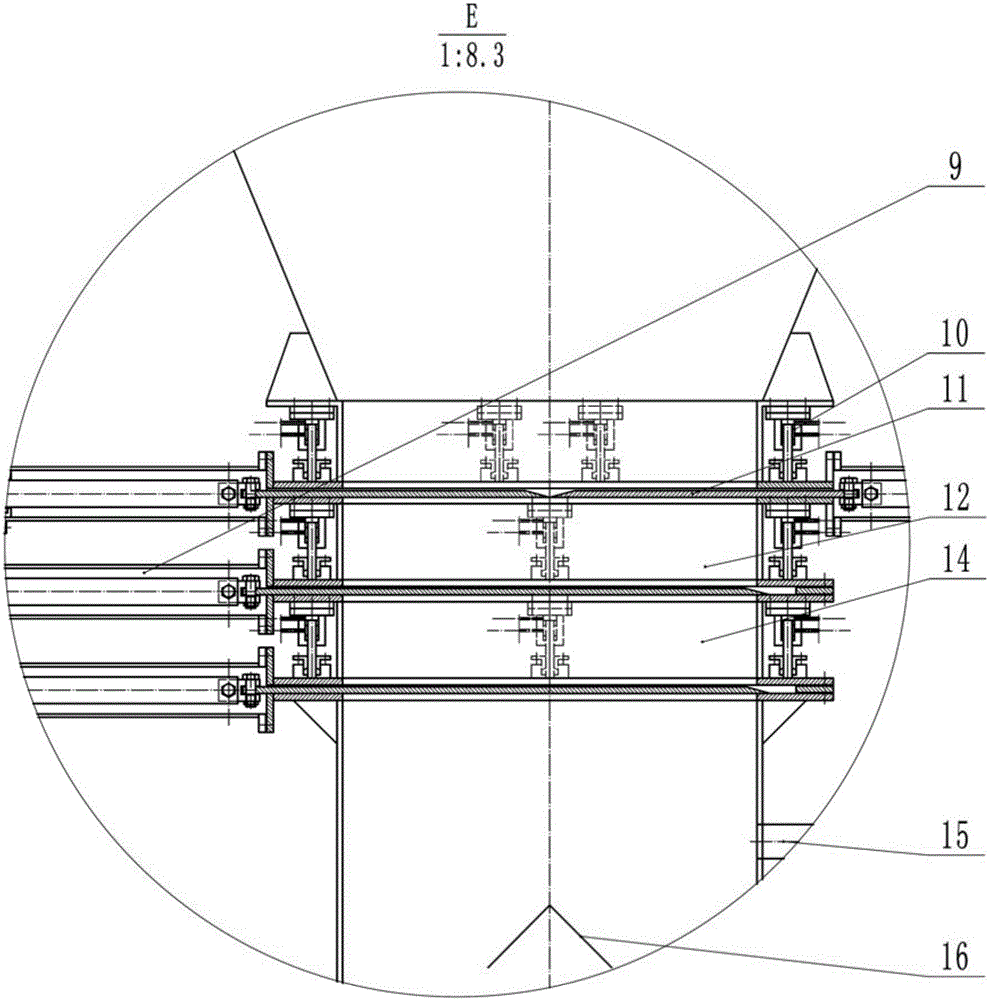

[0018] see Figure 1-Figure 4 , an oil shale gas heat carrier retort furnace that is easy to be enlarged in the present invention includes a furnace body, and the furnace body is composed of a feed section A, a retort section B, a cooling section C and a dry slagging system arranged in sequence from top to bottom D composition, a hopper 1 is set on the top of the furnace body where the feed section A of the furnace body is located, and the hopper 1 is connected with a distributor 2 that extends into the furnace body through a star valve 3 and has several distribution pipes. Oil and gas outlet 4, a sealed first air distribution bellows 5 is provided on the furnace body where the retort section B is located, and a first hood-type air distribution device connected to the first air distribution bellows 5 is provided in the furnace body where the retort section B is located 6. The fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com