High-temperature resisting phosphorus-bromines type solvent-free epoxy matrix resin for carbon fiber cable core and preparation method of epoxy matrix resin

An epoxy matrix and epoxy resin technology, applied in the field of matrix resin, can solve the problems of high price, unfavorable large-scale popularization and application, high cost of polyetherimide resin, and achieve the advantages of convenient operation, low cost and good comprehensive performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Put 100.0 grams of ES216 epoxy resin and 25.0 grams of 2,2-bis[4-(2,4-bismaleimidophenoxy)phenyl]propane into the reaction kettle, stir and mix, and set at 120°C After reacting for 0.5 hours, cool down to below 80°C, add 70.0 grams of reactive diluent CE793, stir and mix evenly to obtain 195.0 grams of component A, which is designated as A1.

[0041] Put 50.0 grams of tetrabromobisphenol A epoxy resin and 10.0 grams of DOPO (9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide) into the reactor, and react at 120 ° C for 0.5 After 1 hour, add 10.0 grams of tetrabromophthalic anhydride, continue the reaction for 0.5 hours, add 30.0 grams of reactive diluent CE793, stir and mix evenly to obtain 100.0 grams of component B, which is designated as B1.

[0042] Component C consists of 100.0 grams of dodecenyl succinic anhydride and 20.0 grams of N,N-dimethyl-p-methylaniline, denoted as C1. Put components A1 and B1 into a reaction kettle, stir and mix at 110°C for 10 minutes, co...

Embodiment 2

[0044] Mix 100.0 grams of ES216 epoxy resin with 2.0 grams of 1,4-bis(2,4-bismaleimidophenoxy)benzene, 2.0 grams of 2,2-bis[4-(2,4-dimaleimide Put imidophenoxy)phenyl]propane into the reaction kettle, stir and mix, react at 100°C for 1.5 hours, cool to below 80°C, add 10.0 grams of reactive diluent CE793, stir and mix evenly, and get 114.0 grams of component A, denoted as A2.

[0045] Put 10.0 grams of tetrabromobisphenol A epoxy resin and 100.0 grams of DOPO (9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide) into the reactor, and react at 100°C for 1.5 After 1 hour, add 85.0 grams of tetrabromophthalic anhydride, continue the reaction for 1.5 hours, add 20.0 grams of reactive diluent CE793, stir and mix evenly to obtain 215.0 grams of component B, which is designated as B2.

[0046] Component C consists of 200.0 grams of methyltetrahydrophthalic anhydride, 100.0 grams of dodecenyl succinic anhydride, 5.0 grams of 2-ethyl-4-methylimidazole, and 5.0 grams of N,N-dimethyl-p-m...

Embodiment 3

[0048] Take an appropriate amount of high temperature resistant phosphorous bromine type solvent-free epoxy matrix resins for carbon fiber cable cores in Example 1 and Example 2 respectively, i.e. CFPM-1 and CFPM-2, and apply them evenly on standard stainless steel test pieces respectively, and let them dry in the air at room temperature. After standing for 10 minutes, stack, clamp, and put it into a blast oven for curing: start from room temperature to 100°C, keep warm for 1.5 hours, continue to heat up to 140°C, keep warm for 1.5 hours, continue to heat up to 170°C, keep warm Reacted for 1.5 hours and cooled naturally to room temperature. The tensile shear strength (σ) test was carried out at room temperature (25°C) and high temperature (240°C) using an electronic tensile machine, and the results are shown in Table 1.

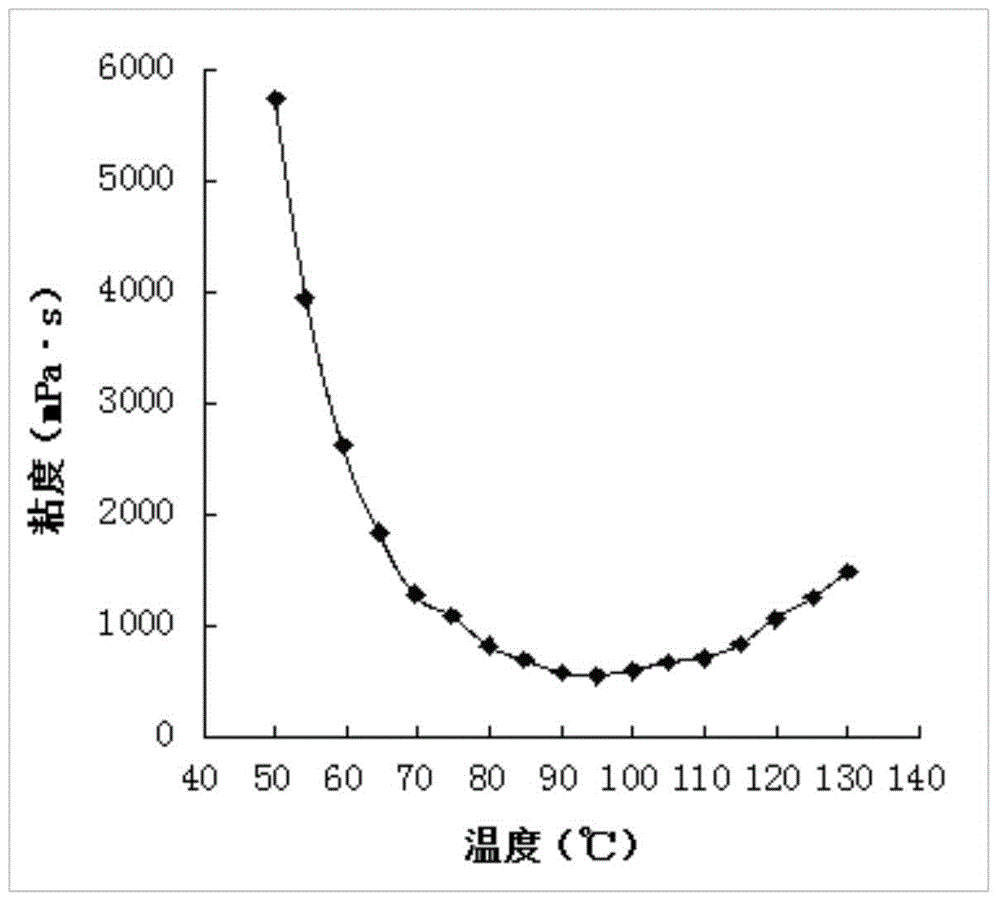

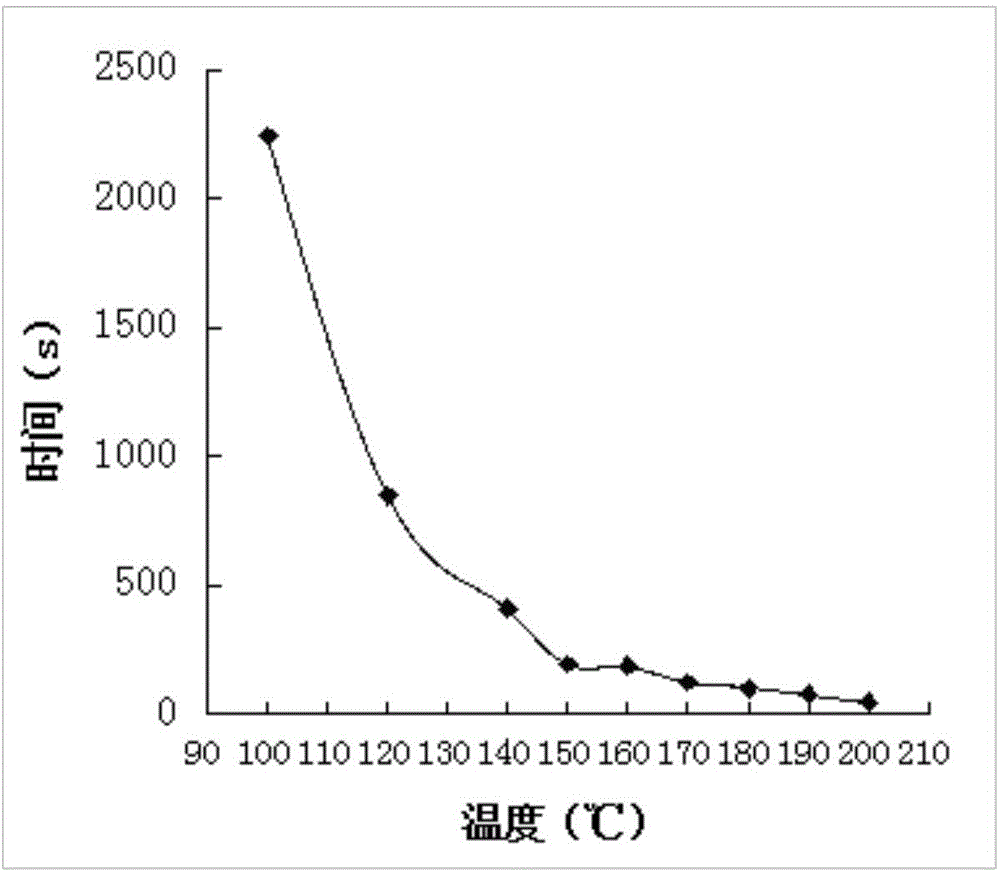

[0049] Take appropriate amount of high temperature resistant phosphorus bromine type solvent-free epoxy matrix resin for carbon fiber cable core of embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com