Flame-retardant thermoplastic dynamic silicon-sulfide rubber and preparation method thereof

A technology of dynamic vulcanization and silicone rubber, which is applied in the field of flame-retardant thermoplastic dynamic vulcanization silicone rubber and its preparation, can solve the problems of no further research on flame-retardant thermoplastic dynamic vulcanization silicone rubber, and achieve large-scale industrial production and excellent mechanical properties. Performance, the effect of improving the flame retardancy of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3 and comparative example 1

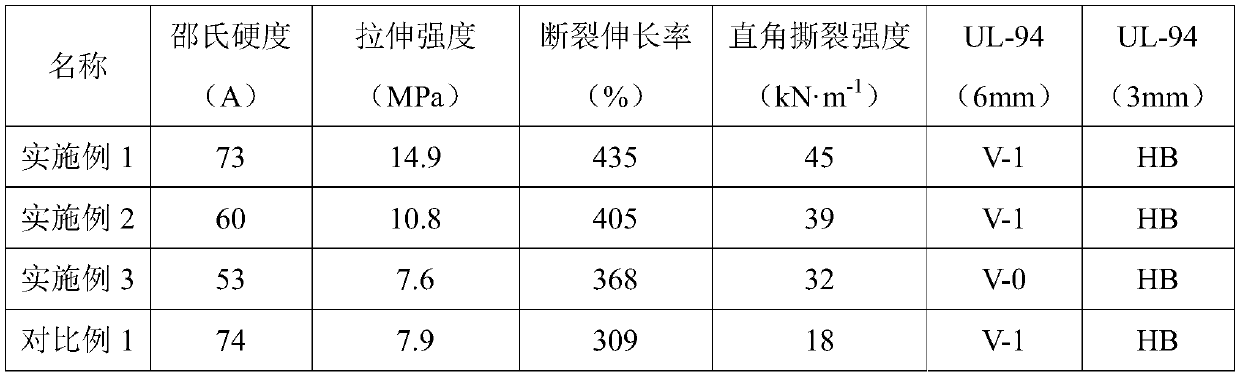

[0030] The silicone rubber compositions of Examples 1-3 and Comparative Example 1 are shown in Table 1, and the compositions stated in Table 1 are all parts by mass.

[0031] The silicone rubber composition of table 1 embodiment 1~3 and comparative example 1

[0032] name

TPU

Silicone rubber compound

Compatibilizer

crosslinking agent

catalyst

flame retardant

Example 1

70

30

5

2.5

0.05

10

Example 2

50

50

5

2.5

0.05

10

Example 3

30

70

5

2.5

0.05

10

Comparative example 1

70

30

5

0

0

10

[0033] The preparation method of the flame-retardant thermoplastic dynamic vulcanized silicone rubber of Examples 1-3 is as follows:

[0034] Step 1) Add thermoplastic polyurethane elastomer (TPU), silicone rubber compound, compatibilizer, crosslinking agent, and flame retardant in the formula shown in Table 1 to the internal mixer, and ...

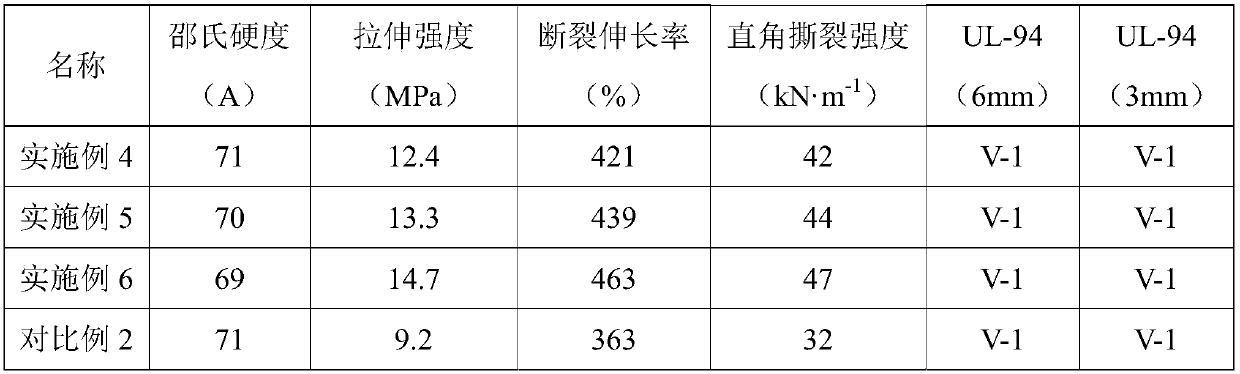

Embodiment 4~6 and comparative example 2

[0042] The silicone rubber compositions of Examples 4-6 and Comparative Example 2 are shown in Table 3, and the compositions stated in Table 3 are all parts by mass.

[0043] The silicone rubber composition of table 3 embodiment 4~6 and comparative example 2

[0044] name

TPU

Silicone rubber compound

Compatibilizer

crosslinking agent

catalyst

flame retardant

Example 4

60

40

5

2

0.1

10

Example 5

60

40

10

2

0.1

10

Example 6

60

40

20

2

0.1

10

Comparative example 2

60

40

0

2

0.1

10

[0045] The preparation method of the flame-retardant thermoplastic dynamic vulcanized silicone rubber of Examples 4-6 is as follows:

[0046]Step 1) Add the thermoplastic polyurethane elastomer (TPU), silicone rubber compound, compatibilizer, crosslinking agent, and flame retardant in the formula shown in Table 3 into the internal mixer, and ...

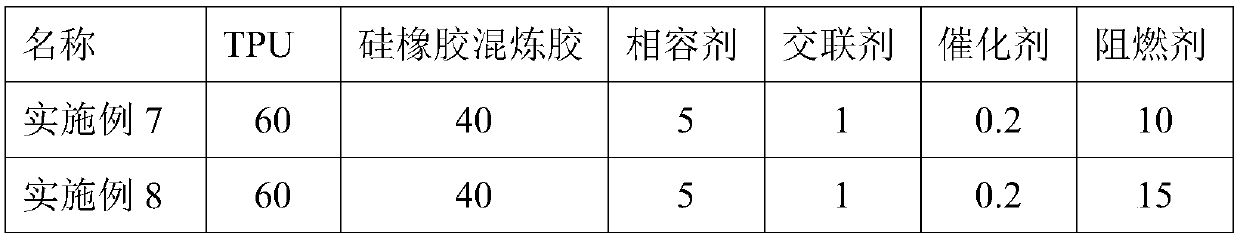

Embodiment 7~10 and comparative example 3

[0055] The silicone rubber compositions of Examples 7-10 and Comparative Example 3 are shown in Table 5, and the compositions stated in Table 5 are all parts by mass.

[0056] The silicone rubber composition of table 5 embodiment 7~10 and comparative example 3

[0057]

[0058]

[0059] The preparation method of the flame-retardant thermoplastic dynamic vulcanized silicone rubber of Examples 7-10 is as follows:

[0060] Step 1) Add the thermoplastic polyurethane elastomer (TPU), silicone rubber compound, compatibilizer, crosslinking agent, and flame retardant in the formula shown in Table 5 into the internal mixer, and set the temperature to 190°C. The rotational speed is 80 rpm, the banburying time is 4 minutes, and the premix is obtained by extrusion and granulation. The thermoplastic polyurethane elastomer used in Examples 7-10 is WHT-8285 of Wanhua Chemical Company, the silicone rubber compound is EN-5150A of Dongjue Silicone Company, the compatibilizer is EMA, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com