Co-N-C catalyst, and preparation method and applications thereof

A catalyst and compound technology, applied in the field of catalyst preparation and application, can solve the problems such as the catalyst cannot be recycled, the added value of the product is reduced, and the product selectivity is not high, and the effect of excellent cycle performance, low cost and broad application prospects can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Under room temperature conditions, accurately weigh 3g melamine and 1.85g cobalt nitrate hexahydrate (m 三聚氰胺 :m Co 2+ =8:1), put the two in a mortar and grind them thoroughly to obtain a blue-green solid powder with uniform color, and obtain the Co-N-C catalyst 1.

[0029] Catalyst 1 prepared by grinding was used to catalyze the conversion of ethylbenzene to acetophenone.

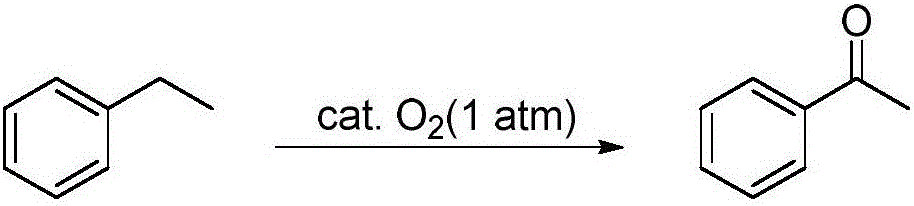

[0030]

[0031] The specific experimental steps are as follows: add 1 mL of ethylbenzene to a 25 mL sealed tube, add 0.5 mol% of Co-N-C catalyst 1, seal it with a rubber stopper, and after purging with oxygen, insert an oxygen balloon to provide oxygen. The reaction was stirred for 20 h under the condition, and the conversion rate of ethylbenzene was 89% and the selectivity of acetophenone was 95% as detected by gas chromatography.

Embodiment 2

[0033] In this example, except that the mass ratios of melamine and cobalt nitrate hexahydrate are different, other parameters and steps for preparing the Co-N-C catalyst 1 are the same as in Example 1, and the specific test results are shown in Table 1.

[0034] Table 1 mass ratio is (1-20): 1 the data of catalyst 1 catalyzing the oxidation of ethylbenzene prepared by the grinding method of melamine and cobalt nitrate hexahydrate

[0035] different ratios 1:1 2:1 3:1 4:1 5:1 6:1 7:1 8:1 9:1 10:1 Conversion rate(%) 83 82 85 84 86 80 82 89 68 62 Selectivity (%) 77 83 84 90 94 92 92 95 96 95 different ratios 11:1 12:1 13:1 14:1 15:1 16:1 17:1 18:1 19:1 20:1 Conversion rate(%) 54 58 55 51 46 42 40 35 37 34 Selectivity (%) 98 96 96 96 98 97 95 98 97 96

Embodiment 3

[0037] By the method of ball milling, at room temperature, accurately weigh 3g melamine and 1.85g cobalt nitrate hexahydrate (m 三聚氰胺 :m Co 2+ =8:1), the two are placed in a ball mill jar, high-energy ball milling, the rotating speed is 200r / min, and the ball milling time is 240min to obtain a blue-green solid powder with uniform color, and obtain the Co-N-C catalyst 2.

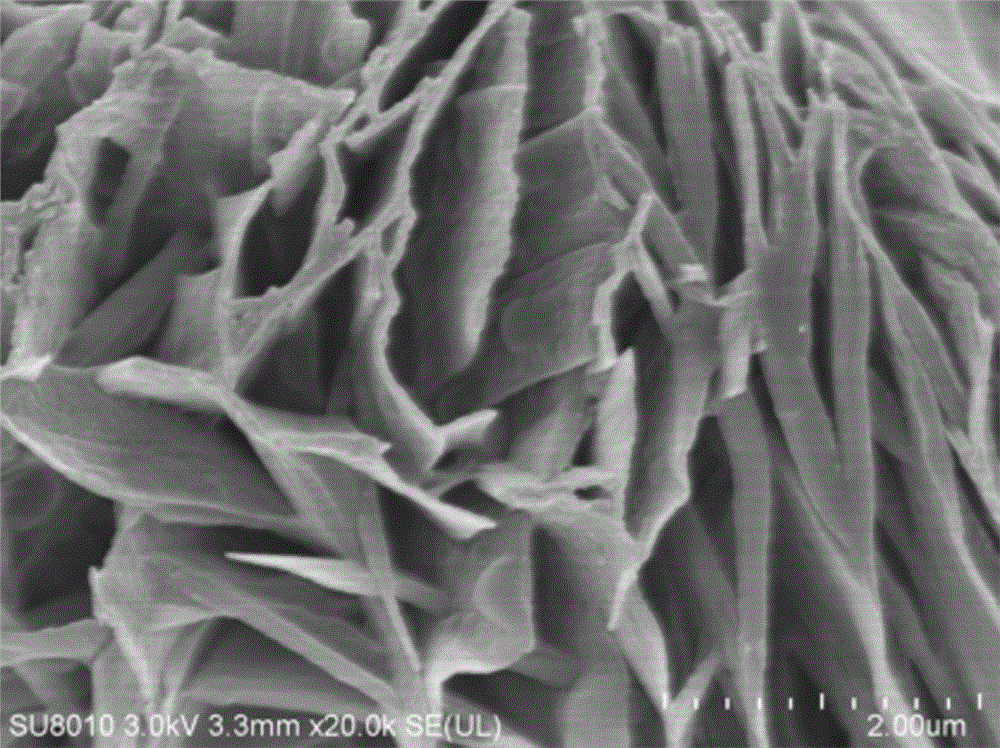

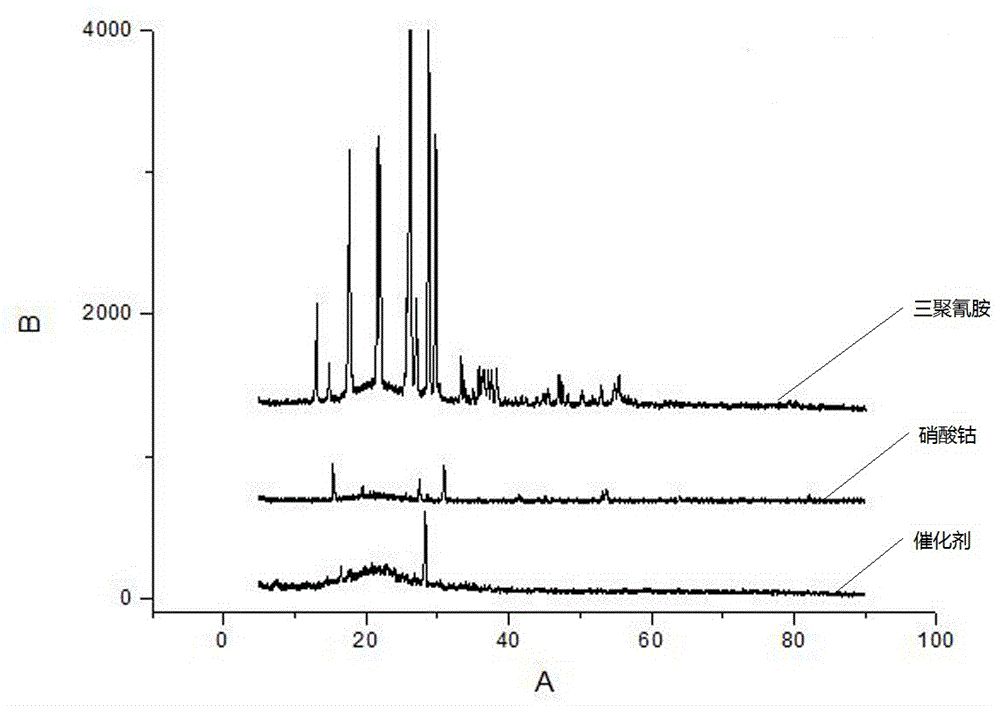

[0038] like figure 1 as well as figure 2 As shown, the prepared Co-N-C catalyst 2 was characterized by scanning electron microscope and XRD. It can be seen from the electron microscope that the catalyst is flake-shaped; from the XRD data, it is shown that the original crystal form of the original cobalt nitrate hexahydrate and melamine was destroyed, and a new crystal form appeared.

[0039] The Co-N-C catalyst 2 prepared by ball milling was used to catalyze the conversion of ethylbenzene to acetophenone.

[0040]

[0041] The specific experimental steps are as follows: add 1mL ethylbenzene to a 25mL ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com