Preparation method for nickel-based glass fiber composite material based on laser cladding

A glass fiber, composite material technology, applied in the direction of metal material coating process, coating, etc., to achieve good resistance to intermetallic friction and wear and low-stress abrasive wear, high corrosion resistance, good toughness and impact resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0031] (1) Select 45# steel with a V-shaped groove as the substrate for cladding. The size of the V-shaped groove is 0.7mm×2.1mm, and it is polished with 600-mesh sandpaper, and then the oil and rust on the surface of the substrate are cleaned with acetone solution;

[0032] (2) Dry the nickel-based powder in a dryer at a temperature of 120°C for 60 minutes;

[0033] (3) Put the glass fiber in the V-shaped groove, pre-set the nickel-based powder on the surface of the 45# steel substrate, and the powder thickness is 1.5mm;

[0034] (4) Use a high-power semiconductor laser for cladding, where the laser power is 3000W. The selected spot width is 2-8mm, and the focal length is 370mm. The scanning speed is 8mm / s, and the protective gas is argon;

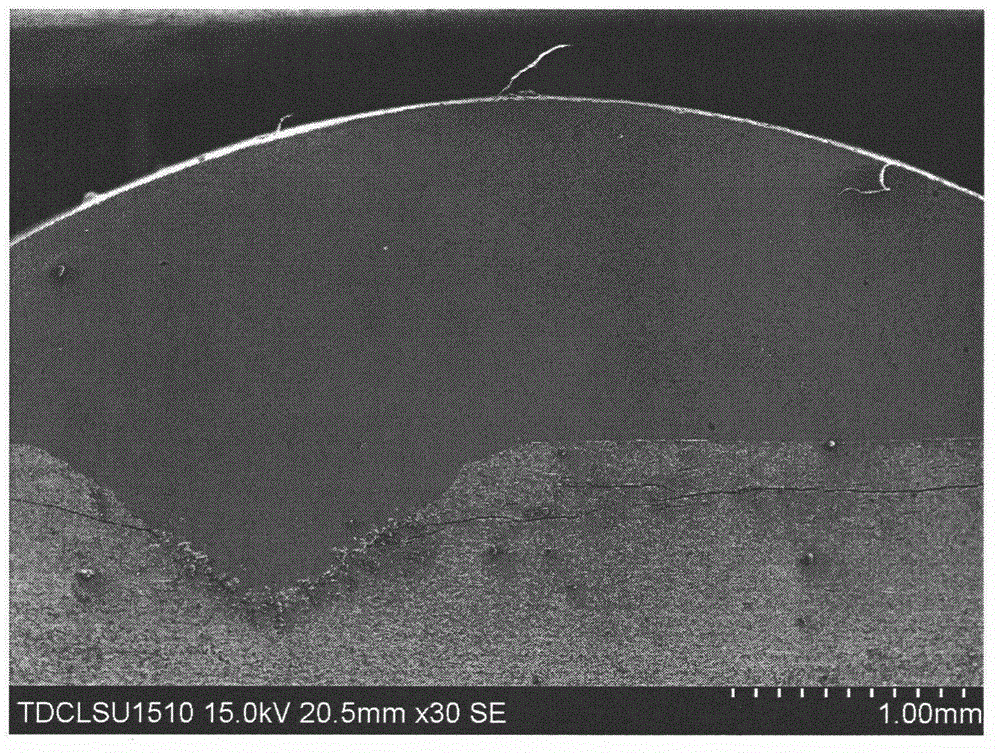

[0035] (5) After the microhardness test, the average hardness of the obtained cladding layer is 384.2HV, and the macroscopic appearance of the cladding layer after cladding is as follows figure 1 As shown, the SEM metallographic pictur...

example 2

[0037] (1) Select 45# steel with a V-shaped groove as the substrate for cladding. The size of the V-shaped groove is 0.7mm×2.1mm, and it is polished with 600-mesh sandpaper, and then the oil and rust on the surface of the substrate are cleaned with acetone solution;

[0038] (2) Dry the nickel-based powder in a dryer at a temperature of 120°C for 60 minutes;

[0039] (3) Put the glass fiber in the V-shaped groove, pre-set the nickel-based powder on the surface of the 45# steel substrate, and the powder thickness is 1.5mm;

[0040] (4) Use a high-power semiconductor laser for cladding, where the laser power is 3000W. The selected spot width is 2-8mm, and the focal length is 370mm. The scanning speed is 16mm / s, and the protective gas is argon;

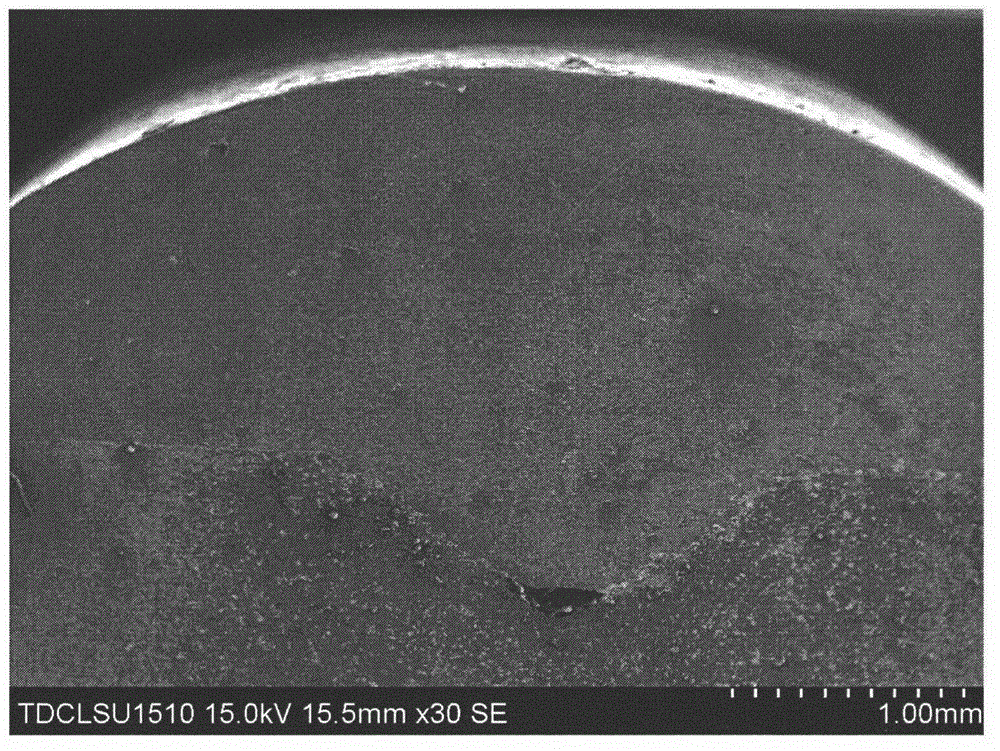

[0041] (5) After the microhardness test, the average hardness of the obtained cladding layer is 307.3HV, and the macroscopic appearance of the cladding layer after cladding is as follows figure 1 As shown, the SEM metallographic pictu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com