Process for novel preparing cutting tooth of coal cutter

A technology for shearers and picks, which is applied in the direction of manufacturing tools, furnace types, heat treatment equipment, etc., can solve the problems of short service life of shearer picks, reduce coal mining costs, prolong service life, and improve coal mining efficiency Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

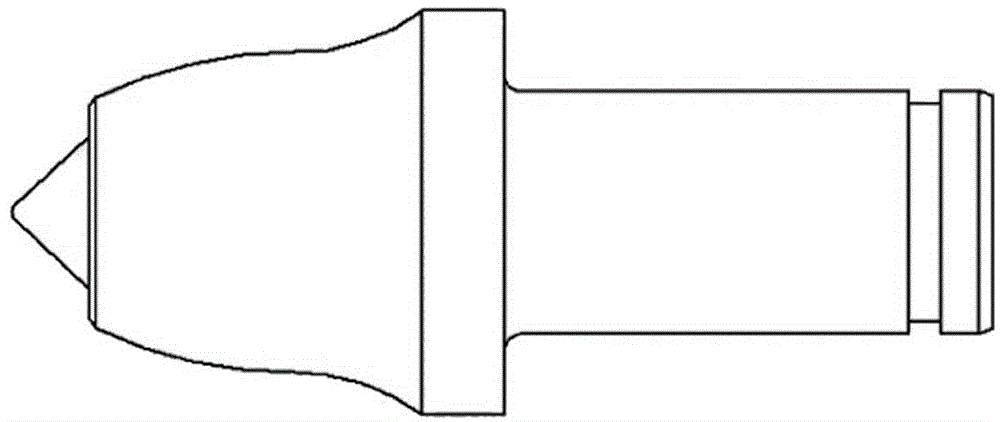

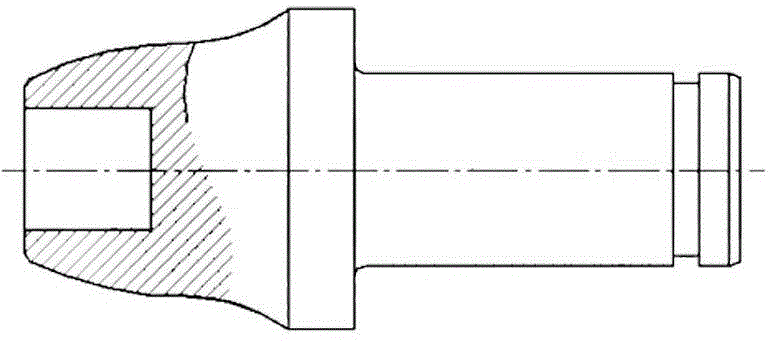

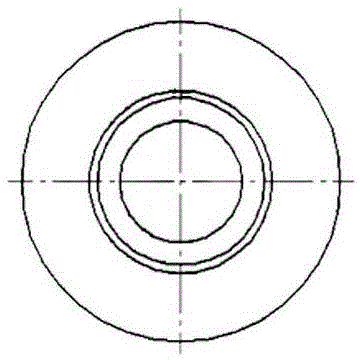

[0021] Below in conjunction with accompanying drawing, the present invention will be further described:

[0022] The purpose of the present invention is to manufacture a new type of cutting tooth for a coal mining machine, which has the same shape and size as the existing cutting tooth, and the cutting body has excellent wear resistance from the inside to the outside, so that it can be extended The service life of picks. In the research process, three important problems must be solved: first, the casting process must ensure uniform structure and composition to improve the wear resistance of cast steel; second, cold work and strengthen the cast pick body. The hardness and wear resistance of the final pick body should exceed the existing pick; the third is to ensure that the hole at the front end of the pick body and the cemented carbide post maintain an interference fit when installing the cemented carbide post, but the amount of interference It must be less than ±0.005mm, so ...

Embodiment 1

[0032] In this example, 50 kg of molten steel was smelted, and 1 kg of wear-resistant alloy was added, the proportion of which was 2%. 49 kg of medium-carbon low-alloy steel raw materials were prepared, accounting for 98% of the total mass of molten steel. The composition of medium carbon low alloy steel is as follows: C: 0.45%; Si: 0.34%; Mn: 0.65%; S: 0.001%; P: 0.001%; Gr: 1.05%; Ni: 2.15%; Mo: 0.50%; Impurities are less than 0.35%, and the balance is iron Fe.

[0033] The implementation process is as follows:

[0034]Using casting technology to prepare a new type of pick body, first prepare the charge according to the above-mentioned medium-carbon low-alloy steel composition, and use an induction furnace to melt the charge first; raise the temperature of the electric furnace to 1550°C to fully melt the charge, remove the slag and carry out rapid pre-furnace composition Analysis to ensure that the composition of the molten steel in the furnace complies with the above-m...

Embodiment 2

[0038] In this embodiment, a total of 50 kg of molten steel was smelted, wherein 4 kg of wear-resistant alloy was added, and its ratio was 8%; 46 kg of medium-carbon low-alloy steel raw material accounted for 92% of the total mass of molten steel, and the described medium-carbon low-alloy composition was as follows: C: 0.3 %; Si: 0.15%; Mn: 0.45%; S: 0.001%; P: 0.001%; Gr: 1.20%; Ni: 1.85%; Mo: 0.6%; .

[0039] The manufacturing process is as follows:

[0040] Use casting technology to prepare a new type of pick body, prepare the furnace charge according to the above-mentioned medium-carbon low-alloy steel composition range, raise the temperature of the electric furnace to 1550°C to melt the charge, remove the slag and conduct a rapid composition analysis before the furnace to ensure that the composition of the molten steel in the furnace meets the requirements. Add wear-resistant alloy to the above-mentioned medium-carbon low-alloy steel, then increase the temperature by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com