Epoxy resin bonding agent cured at normal temperature for roads and bridges and preparation method of epoxy resin bonding agent

An epoxy resin, curing technology at room temperature, applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of inability to resist vehicles and the environment, pavement layer damage, low strength, etc., achieve good flexibility, increase Water resistance and low temperature resistance, and the effect of improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

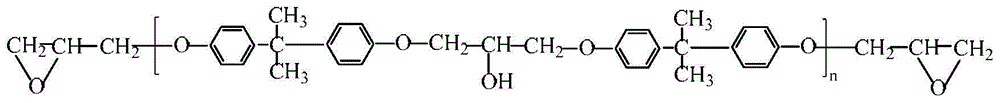

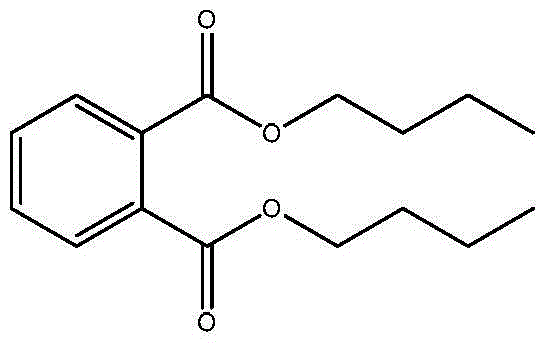

[0036] Embodiment 1: Weigh 100 parts (parts by mass, the same below) bisphenol A glycidyl ether epoxy resin (E51, provided by Wuxi Bluestar Petrochemical Co., Ltd.), add 30 parts of glycidyl ether type flexible epoxy resin ( JEF-0211, provided by Changshu Changshu Jiafa Chemical Co., Ltd.), start stirring, and raise the temperature to 60 ° C, react for 2 hours and cool to room temperature, add 10 parts of dibutyl phthalate (DBP) (Shandong Qilu Plasticizer Co., Ltd. provides) to obtain the A component of the normal temperature curing epoxy resin adhesive for road bridges.

Embodiment 2

[0037] Example 2: Weigh 100 parts of bisphenol A glycidyl ether epoxy resin (E51), add 40 parts of glycidyl ether flexible epoxy resin (JEF-0211), start stirring, and raise the temperature to 60°C , after reacting for 2 hours, cool to room temperature, add 15 parts of nonylphenol (NP) (provided by Jiangsu Lingfei Technology Co., Ltd.), to obtain component A of room temperature curing epoxy resin adhesive for road bridges.

Embodiment 3

[0038] Example 3: Weigh 100 parts of bisphenol A type glycidyl ether epoxy resin (E51), add 35 parts of glycidyl ether type flexible epoxy resin (JEF-0211), start stirring, and raise the temperature to 60°C , After reacting for 2 hours, cool to room temperature, and add 5 parts of dibutyl phthalate (DBP) to obtain component A of room temperature curing epoxy resin adhesive for road bridges.

[0039] The preparation method of component B of normal temperature curing epoxy resin adhesive for road and bridge is as follows:

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com