Corn-shaped nano lanthanum cerium oxide/graphene composite rare earth polishing powder and preparation method thereof

A composite technology of nano-lanthanum oxide and graphene, which is applied in the direction of polishing compositions containing abrasives, can solve problems such as glass that is easy to scratch, and achieve the effects of guaranteed purity, advanced technology, excellent thermal conductivity and ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

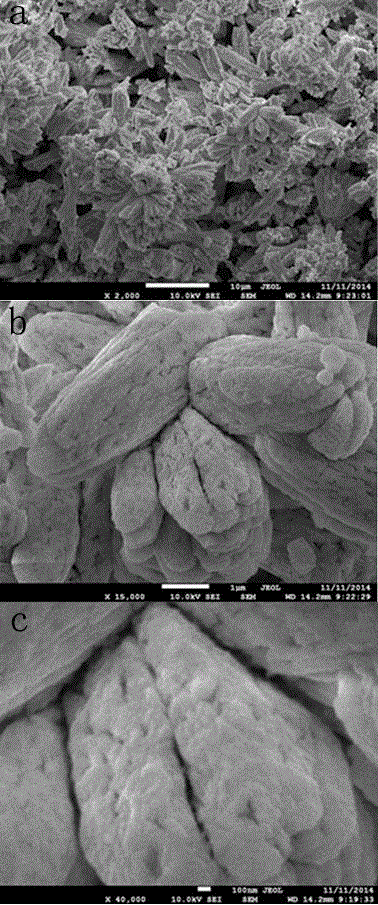

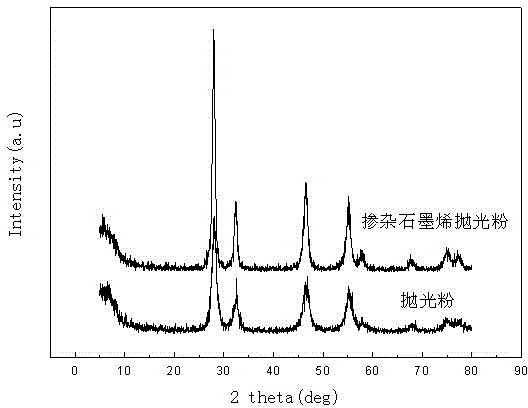

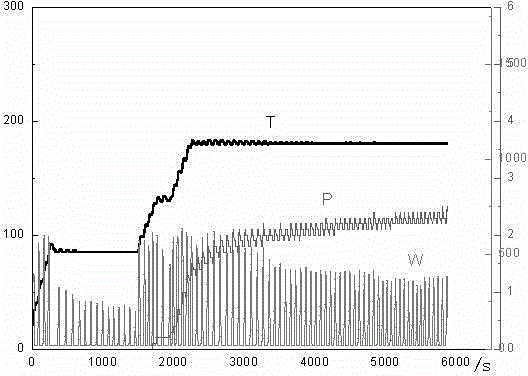

[0025] Weigh 8.9305 g of industrial lanthanum cerium carbonate (atomic ratio La:Ce=1:2) and dissolve it in 50.00 ml of deionized water, slowly add dilute nitric acid, stop adding when the pH of the solution is 6.5~7.0, then add 13.5112 g of urea and 1.0 Add 25.0mL graphene oxide solution with a concentration of 1.0mg / mL to g CTAB, slowly mix the above two solutions, add deionized water to mix evenly and make the volume of the whole solution reach 120mL, transfer it to a microwave hydrothermal reaction tank, Under the condition of constant stirring, the temperature was raised from room temperature to 85°C within 5 minutes and held for 20 minutes, then raised to 180°C within 15 minutes and held for 60 minutes to obtain off-white lanthanum cerium oxide / graphene composite rare earth polishing powder. The morphology of the obtained material is shown in figure 1 As shown in a, the partial enlarged picture is shown in figure 1 b and figure 1 As shown in c, the main body of the obta...

Embodiment 2

[0027] Weigh 7.6860 g of industrial lanthanum cerium carbonate (atomic ratio La:Ce=1:2) and dissolve it in 50.00 mL of deionized water, slowly add dilute hydrochloric acid, stop adding when the pH of the solution is 6.5~7.0, then add 10.8876 g of urea and 2.5 Add 40.0mL graphene oxide solution with a concentration of 1.0mg / mL to g CTAB, slowly mix the above two solutions, add deionized water to mix evenly and make the volume of the whole solution reach 120mL, transfer it to a microwave hydrothermal reaction tank, Under the condition of constant stirring, the temperature was raised from room temperature to 85°C within 5 minutes and held for 25 minutes, then the temperature was raised to 200°C within 15 minutes and held for 30 minutes to obtain off-white lanthanum cerium oxide / graphene composite rare earth polishing powder.

Embodiment 3

[0029] Weigh 10.2784 g of industrial lanthanum cerium carbonate (atomic ratio La:Ce=1:2) and dissolve it in 50.00 mL of deionized water, slowly add dilute sulfuric acid, stop adding when the pH of the solution is 6.5~7.0, then add 15.6840 g of urea and 2.02 Add 20.0mL graphene oxide solution with a concentration of 1.0mg / mL to CTAB, slowly mix the above two solutions, add deionized water to mix evenly and make the volume of the whole solution reach 120mL, then transfer it to a microwave hydrothermal reaction tank. Under the condition of constant stirring, the temperature was raised from room temperature to 85°C within 5 minutes and kept for 30 minutes, then the temperature was raised to 170°C within 15 minutes and kept for 45 minutes to obtain off-white lanthanum cerium oxide / graphene composite rare earth polishing powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com