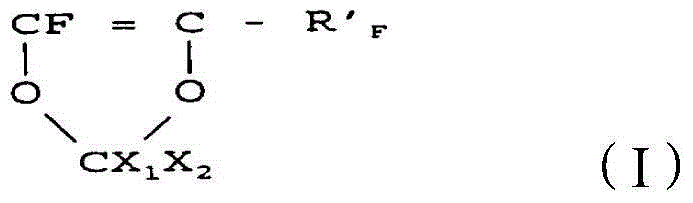

Perfluor dioxole-modified fluorine-containing polymer

A dioxole, polymer technology, applied in offensive equipment, explosives, non-explosive/non-thermal agent components, etc., can solve the problems of limited application, inability to meet military industry, low glass transition temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

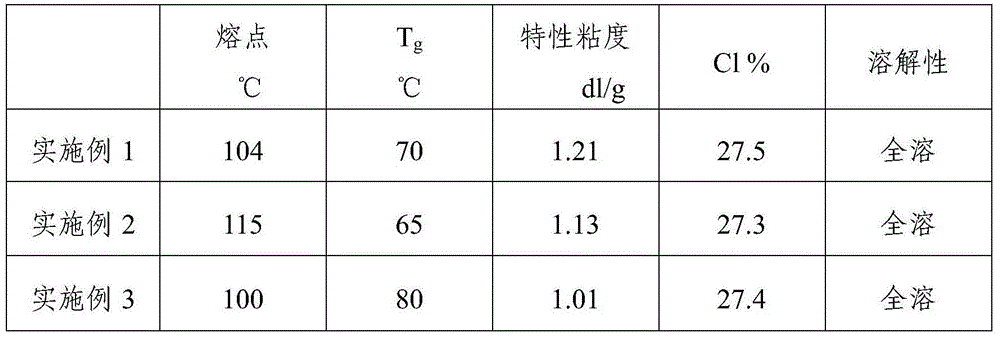

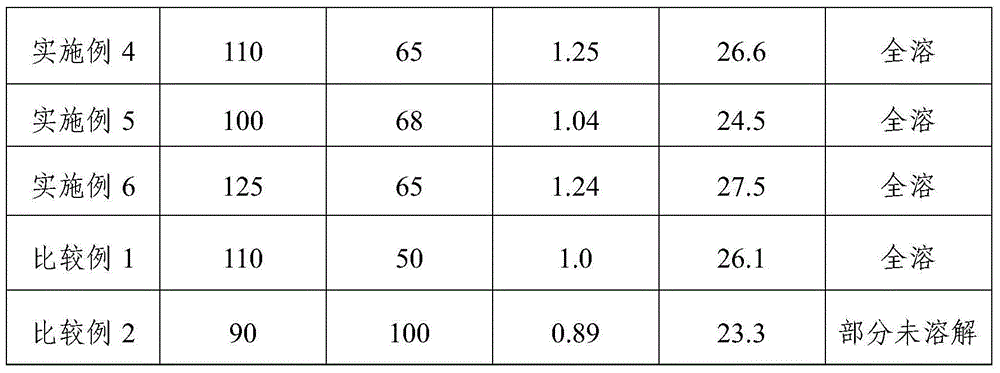

Examples

Embodiment 1

[0047] In a 50L stainless steel reaction kettle with a stirrer, add 30L of deionized water, blow nitrogen and oxygen three times, evacuate until the oxygen content is less than or equal to 25ppm, add 60g of fluorine-containing emulsifier ammonium perfluorooctanoate, 400ml of liquid paraffin (liquid at room temperature), Start stirring at a speed of 200 rpm, raise the temperature to 60°C, and add 85% chlorotrifluoroethylene, 8% vinylidene fluoride and 7% PDD mixed monomer to 2.0 MPa.

[0048] After the system is stable, add 9g of potassium persulfate, 3g of sodium sulfite, 15g of sodium acetate, and 30g of ethanol to start the polymerization reaction. At the same time, continuously add mixed monomers to keep the pressure of the reactor at 3.5 MPa until the solid content of the emulsion in the reactor reaches 30% to stop the reaction.

[0049] Recover the unreacted monomer, release the polymer emulsion, filter paraffin and other impurities, seal and freeze the obtained emulsion ...

Embodiment 2

[0051] In a 50L reactor, add 30L of deionized water, blow nitrogen and deoxygenate three times, evacuate until the oxygen content is less than or equal to 25ppm, add 60g of fluorine-containing emulsifier sodium perfluorooctanoate, 400ml of liquid paraffin (liquid at room temperature), and start stirring at a speed of 200rpm , heat up to 55°C, add 85% chlorotrifluoroethylene, 14.9% vinylidene fluoride and 0.1% PDD mixed monomer to 2.0MPa, after the system is stable, add 4g potassium persulfate and 5 ammonium persulfate composite initiators, 3g partial weight Sodium sulfite, 25g sodium acetate, 10g diethyl malonate, start the reaction. Polymerization begins. Simultaneously add mixed monomer constantly and keep reactor pressure 3.5MPa, stop reaction until emulsion solid content reaches 30% in the reactor, reclaim unreacted monomer, emit polymer emulsion, filter paraffin and other impurity, the emulsion that makes is in Seal and freeze in a frozen alcohol tank at -40°C, then thaw...

Embodiment 3

[0053] Repeat the steps described in Example 1, just add 12g potassium permanganate initiator and 12g oxalic acid, and simultaneously 85% chlorotrifluoroethylene, 5% vinylidene fluoride and 10% PDD mixed monomer. The results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com