Method and device for directly preparing diethyl carbonate by adopting one-step method

A diethyl carbonate, direct technology, applied in the field of diethyl carbonate preparation, can solve the problems of DEC decomposition, catalyst deactivation, low single-pass conversion rate, etc., to improve reaction conversion rate, follow-up separation convenience, and increase conversion rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

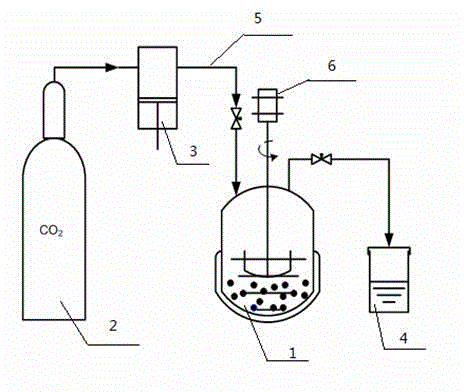

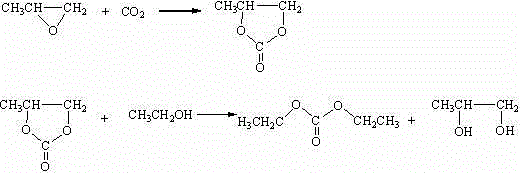

[0025] A method for directly preparing diethyl carbonate by one-step method, comprising the following steps:

[0026] 1) Put 20 mL of absolute ethanol in the reaction kettle, add 20 mL of propylene oxide, and add 0.3 g of two-component metal oxide catalyst K with a mass ratio of 1:0.4 2 O / ZrO 2 , cover and seal well;

[0027] The two-component metal catalyst K 2 O / ZrO 2 Prepared by impregnation method: at 70 ° C, zirconium nitrate was used as the precursor first, and NH 3 ·H 2 After precipitation occurs in O titration, reflux and aging for 6 hours, and ZrO is obtained after drying and roasting. 2 powder; then impregnated with potassium nitrate solution for 6h, then dried and roasted at 600 °C to obtain the catalyst K of double metal oxide 2 O / ZrO 2 ; Potassium nitrate and ZrO 2 The mass ratio of powder is 1:0.4.

[0028] 2) Pass CO 2 Purge and replace the air in the reactor, and then introduce CO 2 Gas to 5MPa, heated to a temperature of 150oC, and then CO 2 Pres...

Embodiment 2

[0034] A method for directly preparing diethyl carbonate by one-step method, comprising the following steps:

[0035] 1) Put 10 mL of absolute ethanol in the reaction kettle, add 30 mL of propylene oxide, and add 0.1 g of two-component metal oxide catalyst K with a mass ratio of 1:0.4 2 O / CeO 2 , cover and seal well;

[0036] Two-component metal oxide catalyst K 2 O / CeO 2 The preparation method is basically the same as Example 1, except that the transition metal is Ce;

[0037] 2) Pass CO 2 Purge and replace the air in the reactor, and then introduce CO 2 Gas to 4MPa, heated to a temperature of 150oC, and then CO 2 Pressurize to a reaction pressure of 7Mpa;

[0038] 3) Turn on the stirring controller, the stirring speed is 600rpm, and react for 8h;

[0039] 4) After the reaction is over, wait for the reactor to cool down to room temperature, release the pressure in the reactor to obtain diethyl carbonate and receive the product with ethanol.

[0040]Product detection ...

Embodiment 3

[0042] A method for directly preparing diethyl carbonate by one-step method, comprising the following steps:

[0043] 1) Put 30 mL of absolute ethanol in the reaction kettle, add 10 mL of propylene oxide, and at the same time add 0.5 g of a two-component metal oxide catalyst MgO / Nu with a mass ratio of 1:0.4 2 o 3 , cover and seal well;

[0044] Two-component metal oxide catalyst MgO / Nu 2 o 3 The preparation method is basically the same as in Example 1, except that the transition metal is Nu, and the alkali metal is Mg;

[0045] 2) Pass CO 2 Purge and replace the air in the reactor, and then introduce CO 2 Gas to 5MPa, heated to a temperature of 150oC, and then CO 2 Pressurize to a reaction pressure of 7Mpa;

[0046] 3) Turn on the stirring controller, the stirring speed is 700rpm, and react for 8h;

[0047] 4) After the reaction is over, wait for the reactor to cool down to room temperature, release the pressure in the reactor to obtain diethyl carbonate and receive t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com