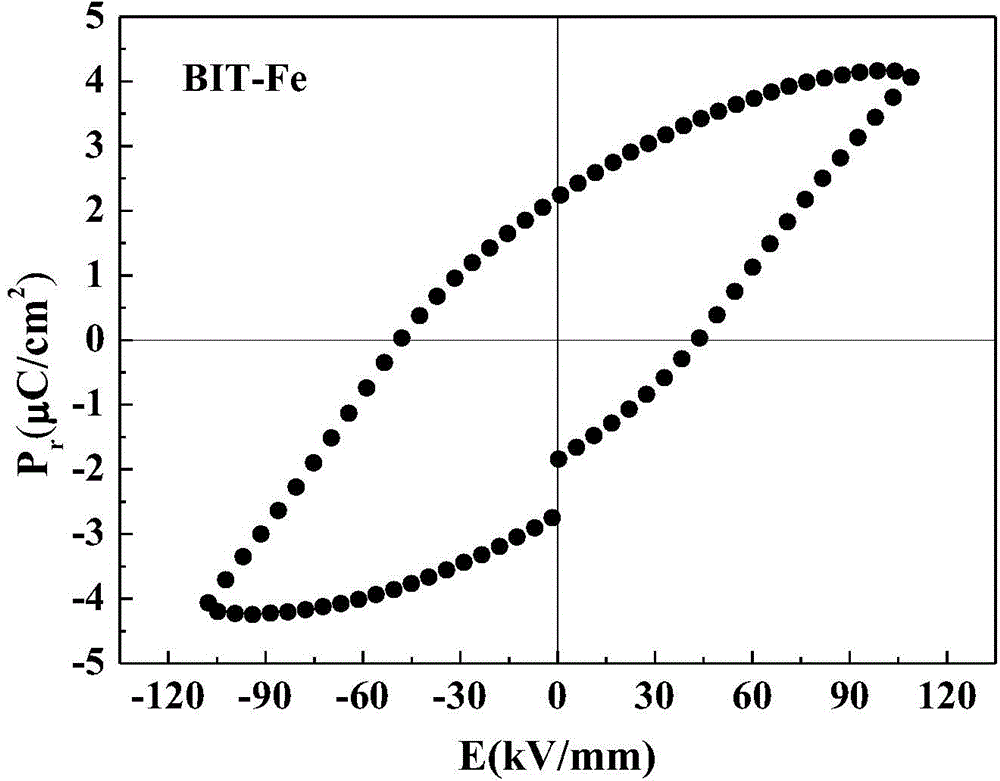

Preparation method of BIT-Fe multiferroic ferroelectric ceramic

A multiferroic and ferroelectric technology, which is applied in the field of preparation of ferroelectric ceramics to achieve the effects of simple and easy-to-obtain dopant and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Step 1: Put Bi 2 o 3 、TiO 2 and Fe 2 o 3 Accurately weigh the materials according to the molar ratio of 2:3:0.01. After mixing, powder A is obtained. According to the mass ratio, powder A: zirconia ball stone: distilled water = 1:3:1. After mixing, ball mill in a ball mill tank for 5 hours;

[0029] Step 2: Dry the powder A after ball milling in step 1 in a constant temperature oven at 70°C for 15 hours, grind and briquette, and then pre-fire it in a muffle furnace. The heating and cooling rates are 3-4°C / min, firstly from room temperature to 400°C, and hold for 10 minutes; then from 400°C to 810°C, and hold for 2.5 hours; then cool down from 810°C to 400°C; finally cool with the furnace to room temperature; grind again to obtain Bi 4 Ti 3 o 12 -Fe 2 o 3 Powder;

[0030] Step 3: Bi according to mass ratio 4 Ti 3 o 12 -Fe 2 o 3 Powder: zirconia ball stone: distilled water = 1:3:1, the Bi obtained in step 2 4 Ti 3 o 12 -Fe 2 o 3 The powder is ball mill...

Embodiment 2

[0032] Step 1: Put Bi 2 o 3 、TiO 2 and Fe 2 o 3 Accurately weigh the materials according to the molar ratio of 2:4:0.1. After mixing, powder A is obtained. According to the mass ratio, powder A: zirconia ball stone: distilled water = 1:5:1.1. After mixing, ball mill in a ball mill tank for 8 hours;

[0033] Step 2: Dry the powder A after ball milling in step 1 in a thermostat at 75°C for 8 hours, grind and briquette, and pre-fire in a muffle furnace. The pre-fire conditions are: in the muffle furnace, follow the temperature The heating and cooling rates are 4~5°C / min respectively. First, the temperature is raised from room temperature to 400°C and held for 10 minutes; then the temperature is raised from 400°C to 820°C and held for 3 hours; Room temperature; regrind to get Bi 4 Ti 3 o 12 -Fe 2 o 3 Powder;

[0034] Step 3: Bi according to mass ratio 4 Ti 3 o 12 -Fe 2 o 3 Powder: zirconia ball stone: distilled water = 1:8:1.2, the Bi obtained in step 2 4 Ti 3 o ...

Embodiment 3

[0036] Step 1: Put Bi 2 o 3 、TiO 2 and Fe 2 o 3 Accurately weigh the materials according to the molar ratio of 3:3:0.06. After mixing, powder A is obtained. According to the mass ratio, powder A: zirconia ball stone: distilled water = 1:1:1.2. After mixing, ball mill in a ball mill tank for 6 hours;

[0037] Step 2: Dry the powder A after ball milling in step 1 in an incubator at 80°C for 12 hours. After grinding and briquetting, pre-fire in a muffle furnace. The pre-fire conditions are: in the muffle furnace, follow the temperature rise The heating and cooling rates are respectively 5-6°C / min. First, the temperature is raised from room temperature to 400°C and kept for 10 minutes; then the temperature is raised from 400°C to 800°C and kept for 2.8 hours; then the temperature is lowered from 800°C to 400°C; to room temperature; grind again to obtain Bi 4 Ti 3 o 12 -Fe 2 o 3 Powder;

[0038] Step 3: Bi according to mass ratio 4 Ti 3 o 12 -Fe 2 o 3 Powder: zirconi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com