Hydrodesulfurization catalyst, preparation method and application thereof

A hydrodesulfurization and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of low catalyst activity and few active components, achieve high hydrodesulfurization performance, improve Active, interaction-reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation of modified titania-alumina composite support:

[0038] The titania-alumina composite carrier was prepared according to the method in Example 1 of the published patent CN1184289C. Take the specific surface area as 160m 2 / g, 90g of clover-shaped alumina with a pore volume of 0.58ml / g and a most probable pore diameter of 130 angstroms, impregnated with 53ml of titanium sulfate in a 0.557g / ml dilute sulfuric acid solution, stirred for 15 minutes, and dried at 120°C for 8 hours Then, calcined at 900°C for 4 hours to obtain titanium oxide-alumina composite oxide A 1 , namely titania-alumina composite support. The resulting titanium oxide-alumina composite oxide A 1 The titanium oxide content is 10% by weight, and the specific surface area is 144m 2 / g, the pore volume is 0.56ml / g, and the most probable pore diameter is 125 angstroms.

[0039] Get 21.7g of cobalt nitrate hexahydrate and 12.4g of cerium nitrate hexahydrate to form a solution, add water to mak...

Embodiment 2

[0043] The steps are the same as in Example 1, the difference is that.

[0044] Get 21.7g of cobalt nitrate hexahydrate and 13.6g of lanthanum nitrate hexahydrate to form a solution, add water to prepare a 140mL mixed solution, add 100g of titanium oxide-alumina to the solution obtained by preparing cobalt nitrate hexahydrate and cerium nitrate hexahydrate Composite oxide A 1 , stirred for 20 minutes, dried at 120°C after draining the water, and then calcined at 600°C for 4 hours to obtain the modified titanium oxide-alumina composite oxide A 3 , namely the modified titania-alumina composite support A 3 .

[0045] Prepare 20ml of ammonia water impregnation solution containing 2.1g of nickel hypophosphite, the pH of the impregnation solution is 9.0, at room temperature, take 10g of modified titanium oxide-alumina composite carrier A 3 , impregnated with impregnation solution, dried at 120°C for 24 hours, then calcined at 550°C for 4 hours, taken out and cooled to room temper...

Embodiment 3

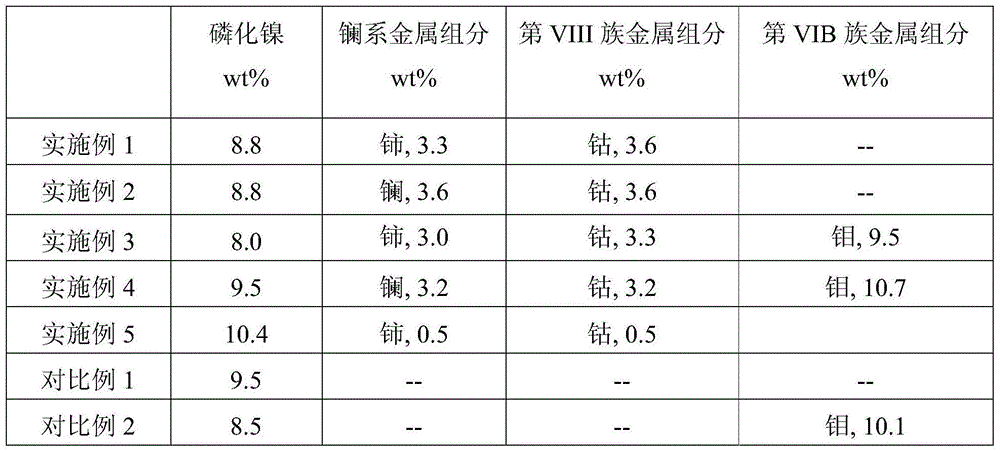

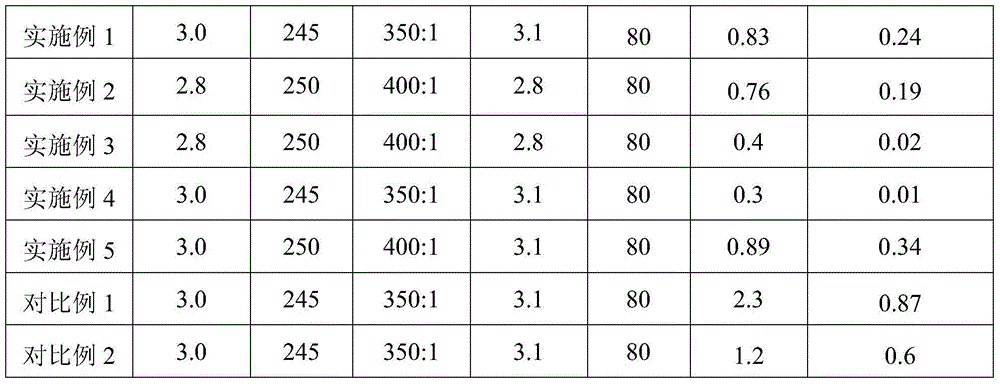

[0048] The steps are the same as in Example 1, except that the impregnation solution contains 2.1 g of nickel hypophosphite and 2.3 g of ammonium molybdate. Catalyst data are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com