Method for producing tert-butylamine by direct catalytic amination of isobutene

A technology of isobutylene and tert-butylamine, which is applied in the field of organic amine production, can solve the problems of high temperature in the preparation process, low reaction conversion rate, equipment corrosion, etc., and achieve the effects of long catalyst life, avoiding polymerization, and avoiding high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

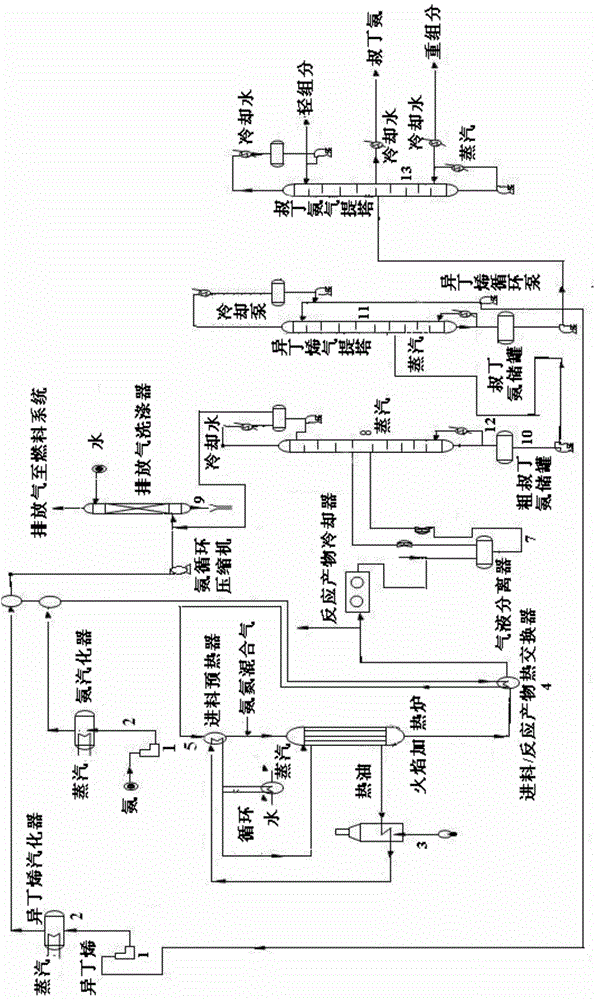

Method used

Image

Examples

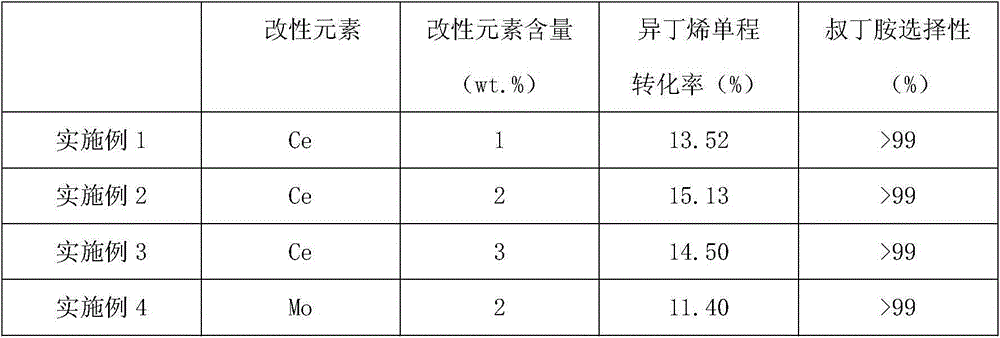

Embodiment (1~10

[0046] Catalyst of the present invention can be prepared by following method:

[0047] (1) The original powder of silica-alumina molecular sieve was mixed with 0.5mol / mL NH 4 The Cl aqueous solution is refluxed and condensed at about 80°C for ion exchange, washing, drying at 110°C, and then roasted to obtain H-type silica-alumina molecular sieve raw powder.

[0048] (2) The H-type silica-alumina molecular sieve raw powder obtained in step 1 is respectively loaded with nitrate, sulfate or carbonate of modifying elements, aged for 12 hours, dried at 110°C for 2 hours, and roasted A modified silica-alumina molecular sieve was obtained.

[0049] (3) Grafting the modified silica-alumina molecular sieve prepared in step 2 with an organic halide in a chemical bonding method.

[0050] (4) The modified silica-alumina molecular sieve prepared in step 3 and the binder boehmite or γ-Al 2 o 3 Mixing, forming, drying and roasting the formed product to obtain a modified silica-alumina mo...

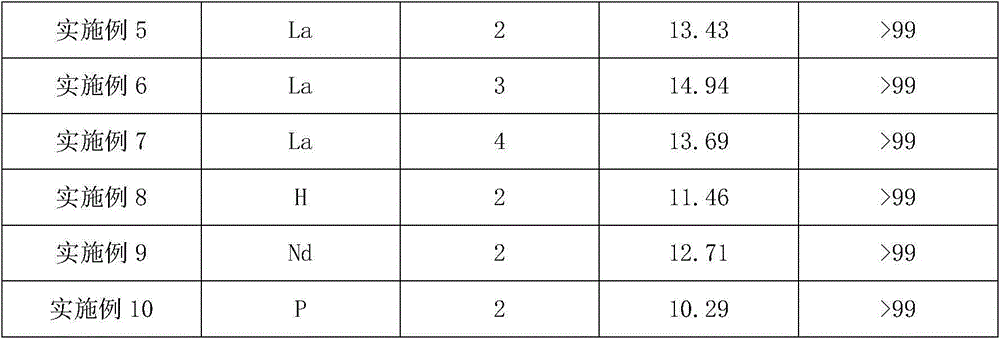

Embodiment 11~13

[0058] According to the method of embodiment 6, just changing the reaction temperature is 260 ℃, 300 ℃, 320 ℃, and the results are listed in table 2.

[0059] Table 2:

[0060]

Embodiment 14~16

[0062] According to the method of embodiment 6, just changing reaction pressure is 5.0MPa, 8.0MPa, 11.0MPa, and reaction result is listed in table 3.

[0063] table 3:

[0064]

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com