Combined treatment method for acid sludge and desulfurization ash

A disposal method and desulfurization ash technology, applied in the direction of solid waste removal, etc., can solve the problems of complicated product purification, inability to realize industrialized production, and difficult utilization, achieve good economic and environmental benefits, and facilitate subsequent resource utilization. , does not produce the effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

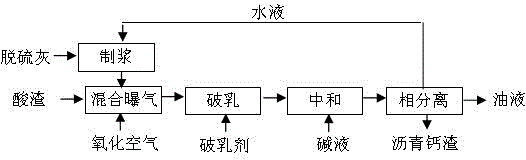

[0084] Such as figure 1 As shown, it is a method for joint disposal of lubricating oil regeneration waste acid slag and dry / semi-dry desulfurization ash, including the following steps:

[0085] (1) Desulfurization ash and acid residue

[0086] The desulfurization ash is taken from the circulating fluidized bed dry sintering flue gas desulfurization device, the main component is: CaSO 4 ·H 2 O, 16.7%, CaSO 3 1 / 2H 2 O, 42.6%, f-CaO, 14.3%, Ca(OH) 2 , 9.5%, CaCO 3 , 6.5%, the total mass percentage of the latter four substances is 72.9%.

[0087] Acid residue is the acid residue produced by the sulfuric acid-clay regeneration process of waste lubricating oil. 4 2- 66.4%, oil content 85.6mg / g, poor fluidity, high viscosity, sulfur content 20%, mainly as residual sulfuric acid, oil, colloid, asphaltenes, heavy aromatics, petroleum sulfonic acid, naphthenic acid , sulfuric acid ester, polymer condensate, heavy metal compound, salt mixture.

[0088] Take 200 g of acid slag a...

Embodiment 2

[0098] Such as figure 1 As shown, it is a method for joint disposal of lubricating oil regeneration waste acid slag and dry / semi-dry desulfurization ash, including the following steps:

[0099] (1) Desulfurization ash and acid residue

[0100] The desulfurization ash is taken from the flue gas desulfurization system of the rotary spray semi-dry coal-fired power plant, the main component is: CaSO 4 ·H 2 O, 26.5%, CaSO 3 1 / 2H 2 O, 32.6%, f-CaO, 10.3%, Ca(OH) 2 , 8.8%, CaCO 3 , 4.5%, the total mass percentage of the latter four substances is 56.2%.

[0101] Acid residue is the acid residue produced by the sulfuric acid-clay regeneration process of waste engine oil, which is in the form of black grease, with a pH value 4 2- 60.4%, oil content 75.8mg / g, poor fluidity, high viscosity, sulfur content 30%, mainly as residual sulfuric acid, oil, colloid, asphaltene, naphthenic acid, sulfuric acid ester, polymer condensation mixtures of substances, heavy metal compounds, and sal...

Embodiment 3

[0112] Such as figure 1 As shown, it is a method for joint disposal of lubricating oil regeneration waste acid slag and dry / semi-dry desulfurization ash, including the following steps:

[0113] (1) Desulfurization ash and acid residue

[0114] The desulfurization ash is taken from the gas suspension absorption dry process coal-fired power plant flue gas desulfurization device, the main component is: CaSO 4 ·H 2 O, 15.8%, CaSO 3 1 / 2H 2 O, 38.9%, f-CaO, 10.5%, Ca(OH) 2 , 8.6%, CaCO 3 , 4.3%, the total mass percentage of the latter four substances is 62.3%.

[0115] Acid residue is the acid residue produced by the sulfuric acid-clay regeneration process of waste oil sludge, which is in the form of black ointment, with a pH value of 4 2- 44.8%, oil content 65.4mg / g, poor fluidity, high viscosity, sulfur content 5%, mainly as residual sulfuric acid, oil, colloid, asphaltene, naphthenic acid, sulfuric acid ester, polymer condensation mixtures of substances, heavy metal compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com