A new midanate pharmaceutical composition and preparation method thereof

A technology of midanacin and composition, which is applied in the field of pharmaceutical composition for treating urinary incontinence, can solve problems such as low dissolution rate, poor stability, and poor content uniformity, and achieve fast dissolution rate, good stability, and reduced impurities the increased effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

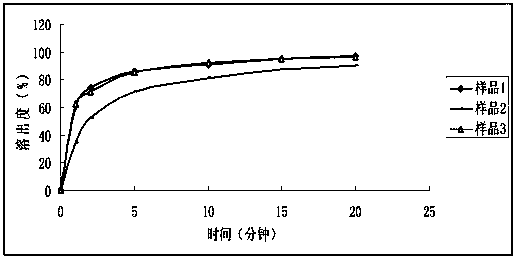

[0040] Content uniformity and dissolution rate comparison test

[0041] (1) Sample preparation

[0042] Preparation of Sample 1

[0043] Weigh 0.1g of midazine, add polyethylene glycol 200 4.0g, ultrasonically dissolve the midazine, add microcrystalline cellulose 302140g to fully mix, add 50g of pregelatinized starch as diluent, lubricant micropowder silica gel 1.0 g, after mixing evenly, press into tablets. Specification 0.1mg, tablet weight 200mg.

Embodiment 2

[0067] prescription

[0068] Accurately weigh 0.1 g of midanacin, add 2.0 g of polyethylene glycol 200, and sonicate for 10 minutes to dissolve the midanacin. Add microcrystalline cellulose to midanacin polyethylene glycol solution, mix at high speed for 2 minutes, add part of pregelatinized starch, mix at high speed for 1 minute, add binder (HPMC50 5% solution) at high speed After shearing and granulating, after obtaining suitable granules, take the material out of the equipment, dry it in an oven at 50°C for 3 hours, and sieve through a 20-mesh sieve for granulation. Add 0.2% magnesium stearate and mix and compress into tablets.

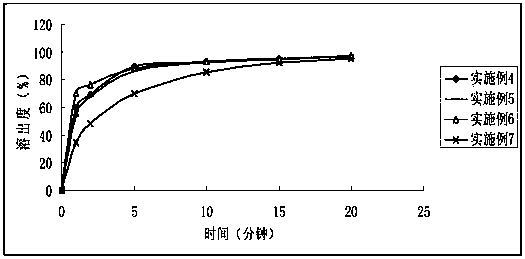

[0069] Table 4 Dissolution test results

[0070]

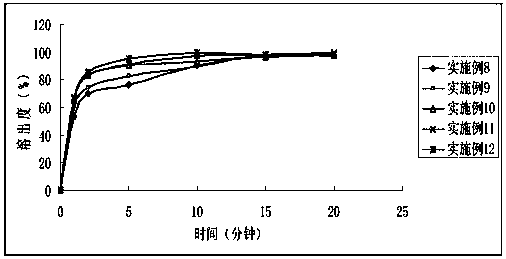

Embodiment 3

[0072] Midana new oral disintegration tablet

[0073]

[0074] Make a solution of the prescribed amount of midanacin solvent in polyethylene glycol, add microcrystalline cellulose to absorb the solution, add microscopic silica gel to absorb the excess solution, and obtain a fluid powder; add mannitol, sodium carboxymethylcellulose, Aspartame, the mixed powder is fully mixed with a high-speed shear mixing granulator, the mixed powder is added to the lubricant magnesium stearate and then compressed, and the pressure is adjusted to make the tablet hardness about 4kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com