Carbonaceous material for negative electrode of nonaqueous-electrolyte secondary battery, process for producing same, and negative electrode and nonaqueous-electrolyte secondary battery obtained using said carbonaceous material

A non-aqueous electrolyte, secondary battery technology, applied in non-aqueous electrolytes, secondary batteries, battery electrodes, etc., can solve the problems of crystal expansion and shrinkage, structural damage, reduction of high temperature cycle characteristics, etc., to improve high temperature cycle characteristics, deviation Small, uniform quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0271] 171 g of 35% hydrochloric acid (special grade manufactured by Junsei Chemical Co., Ltd.) was added to 2000 g of the extracted coffee residues (with a moisture content of 65%), and 5830 g of pure water was added to achieve a pH of 0.5. It was stirred for 1 hour at a liquid temperature of 20°C, and then filtered to obtain acid-treated coffee extract residue. Then, the water washing operation was repeated three times (6000 g of pure water was added to the acid-treated coffee extraction residue, and the mixture was stirred for 1 hour), and deashing treatment was performed to obtain a deashing coffee extraction residue.

[0272] The obtained degreased coffee extraction residue was dried in a nitrogen atmosphere at 150°C, and then tarred in a tubular furnace at a temperature of 380°C for 1 hour to obtain a detarred and deashed coffee extraction residue. Put 50 g of the obtained tarred and deashed coffee extract residues into an aluminum box, and perform oxidation treatment at 22...

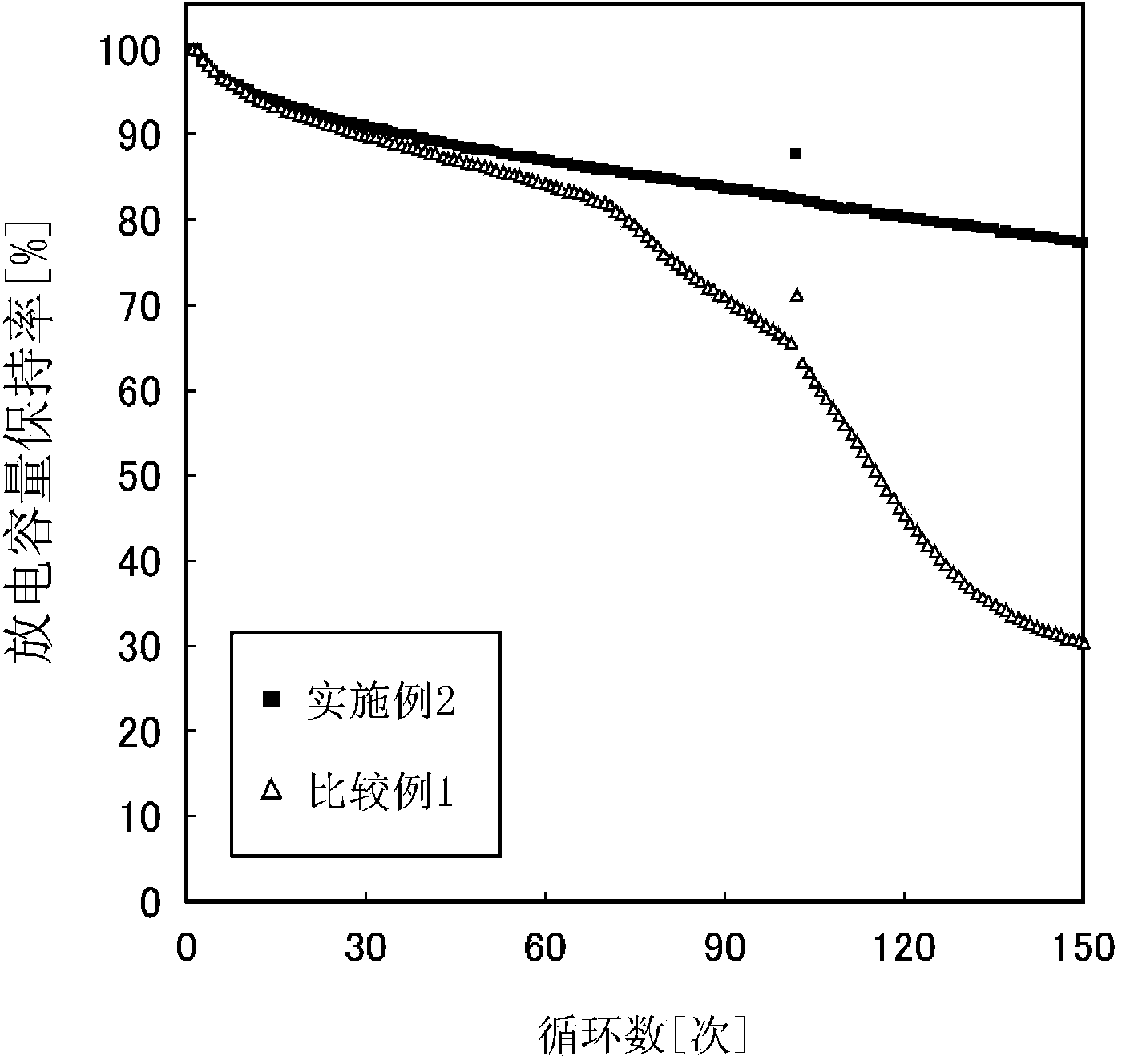

Embodiment 2

[0275] Except that the oxidation treatment temperature of Example 1 was changed to 260° C., the same method as that of Example 1 was used to obtain carbonaceous material 2.

Embodiment 3

[0277] Except that the oxidation treatment temperature of Example 1 was changed to 300° C., the same method as Example 1 was used to obtain carbonaceous material 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com