Novel bipolar plate for vanadium battery and preparation method thereof

A bipolar plate and vanadium battery technology, applied in battery electrodes, fuel cells, circuits, etc., can solve the problems of high resistivity and large contact resistance of composite bipolar plates, meet the requirements of ensuring consistency, reduce contact resistance, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

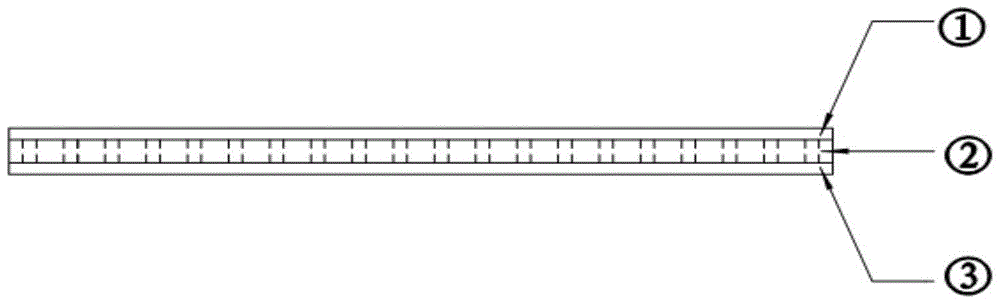

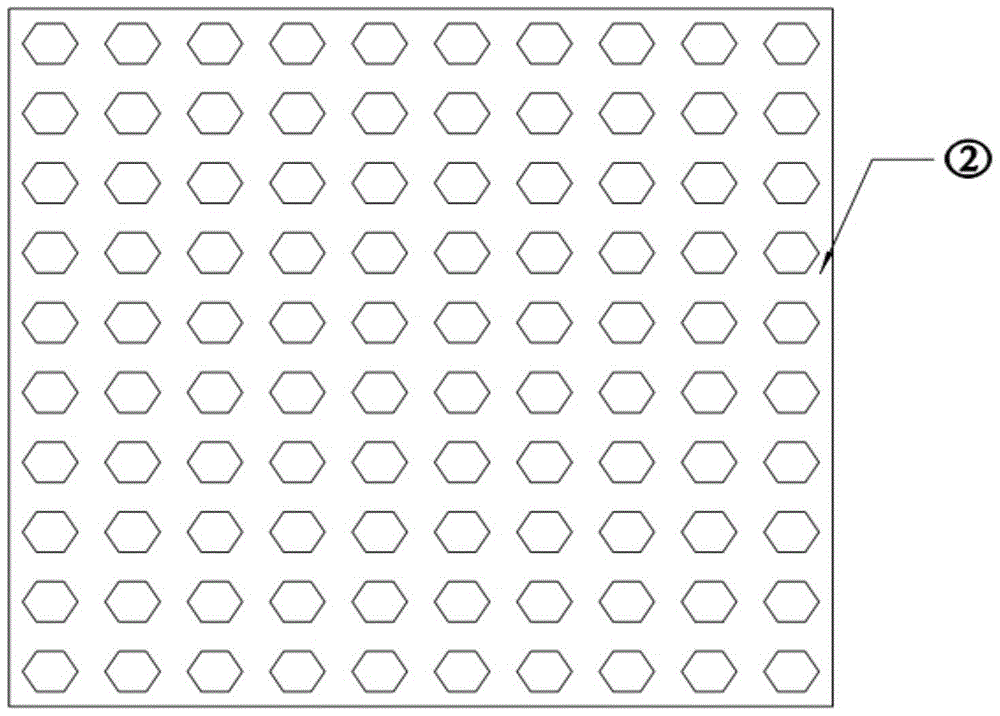

[0022] The preparation method of the bipolar plate for the vanadium battery, the specific steps are as follows:

[0023] 1) Put the grid-shaped resin plate 2 with through-holes on both sides into the bottom layer of the mold, add conductive fillers and put them into the holes (grids), and make a low-conductivity plastic plate as the skeleton layer after hot pressing. The hot-pressing temperature is 100-300°C (preferably 150-200°C), the hot-pressing time is 5-200min (preferably 10-30min), and the hot-pressing pressure is 0.1-25MPa (preferably 1-20MPa).

[0024] Among them, the conductive filler is carbon fiber powder; or, the conductive filler uses carbon fiber powder as the main agent and conductive carbon black as the auxiliary agent; when carbon fiber powder and conductive carbon black are selected, the mass ratio of the two is (1:1)~(1: 10), the preferred mass ratio is (1:2)-(1:5). The particle size of the conductive carbon black is 10 μm to 500 μm, and the particle size o...

Embodiment 1

[0028] First, take a polyethylene resin plate (PE) (specification: length 300mm×width 300mm×thickness 1mm), first put a grid-shaped polyethylene resin plate with holes on both sides into the bottom layer of the mold, and then choose conductive agent carbon fiber powder 50g and Add 100g of carbon black powder into the hole (grid), close the mold, hot-press at 180°C, 20min for 20min, and 5MPa to obtain a low-conductivity plastic plate with a skeleton layer, then select 1mm thick pure graphite powder and put it into the At the bottom of the mold, put a low-conductivity plastic plate, put 1mm thick pure graphite powder on the conductive plastic plate to close the mold, hot-press temperature is 180°C, hot-press time is 20min, pressure is 15MPa, and a new type of vanadium battery is obtained. bipolar plate.

[0029] In the present embodiment, the technical parameters and performance indicators of the vanadium battery bipolar plate are as follows:

[0030] The volume resistivity of ...

Embodiment 2

[0032] First, take a polypropylene resin board (PP) (specification: length 300mm×width 300mm×thickness 1mm), put a grid-shaped polypropylene resin board with holes on both sides into the bottom of the mold, and then choose conductive agent carbon fiber powder 50g and Add 100g of carbon black powder into the hole, close the mold, hot pressing temperature is 180°C, hot pressing time is 20min, and pressure is 10MPa to obtain a low-conductivity plastic plate with a skeleton layer, then select 2mm thick pure carbon black and put it on the bottom of the mold first, Then put a low-conductivity plastic plate, put 2mm thick pure carbon black on the conductive plastic plate to close the mold, the hot-pressing temperature is 180°C, the hot-pressing time is 20min, and the pressure is 10MPa, and a new bipolar plate for vanadium battery is obtained.

[0033] In the present embodiment, the technical parameters and performance indicators of the vanadium battery bipolar plate are as follows:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com