A simple method for pretreatment-acid leaching of NdFeB waste

A NdFeB and acid leaching technology, which is applied in the field of comprehensive utilization of waste resources, can solve the problems of high operating intensity, low actual conversion rate, and reduced production effect, and achieve the effect of improving oxidation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

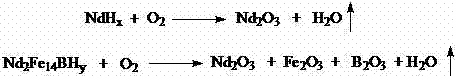

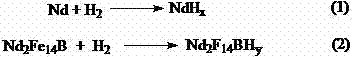

Method used

Image

Examples

Embodiment 1

[0043] Take a batch of NdFeB waste mainly from the machining of magnetic materials, and its solid content is 95%.

[0044] After testing, based on 1Kg of solids, there are 960.5g of NdFeB alloy in the waste, 20.3g of various oxides and compounds, and 19.2g of obvious physical impurities; the composition of NdFeB alloy is Nd 32.80 Fe 66.10 B 1.1 .

[0045] (1) Take a batch of NdFeB waste (as above, 1000Kg after folding and solidification), and separate the obvious impurities by physical separation.

[0046] (2) Put the above-mentioned NdFeB waste into the hydrogenation basket, place it in a hydrogenation device without a dehydrogenation unit, and put it at room temperature, H 2 Press 4×10 5 Under the condition of Pa, hydrogen is introduced, and after the hydrogenation amount reaches more than 380g, it enters the rapid hydrogen absorption stage, and the waste material rapidly bursts and breaks during the hydrogenation process, and the damage is further accelerated in the rap...

Embodiment 2

[0053] Take a batch of NdFeB waste, mainly from the scraps produced in the machining of magnetic materials and the grinding mud produced in the grinding process, with a solid content of 92%.

[0054] After testing, based on 1Kg of solids, there are 919.9g of NdFeB alloy in the waste, 49.8g of oxides and compounds, and 30.3g of obvious physical impurities; the composition of NdFeB alloy is Nd 32.73 Fe 66.17 B 1.1 .

[0055] (1) Take a batch of NdFeB waste (as above, 1000Kg after folding and solidification), and separate the obvious impurities by physical separation.

[0056] (2) Put the above-mentioned NdFeB waste into the hydrogenation basket, place it in a hydrogenation device without a dehydrogenation unit, and put it at room temperature, H 2 Press 3×10 5 Under the condition of Pa, hydrogen is introduced, and after the hydrogenation amount reaches more than 360g, it enters the rapid hydrogen absorption stage, and the waste material rapidly bursts and breaks during the hy...

Embodiment 3

[0063] A batch of NdFeB waste was taken, mainly from the scraps produced in the machining of magnetic materials, the grinding mud produced in the grinding process and the waste slag produced in the smelting process, with a solid content of 91%.

[0064] After testing, calculated by 1Kg solid amount, 927.4g of NdFeB alloy, 50.2g of oxide and compound total amount, 22.4g of obvious physical impurities in the waste material; wherein the composition of NdFeB alloy is (Dy 3 Gd 1 Nd 96 ) 32.73 Fe 66.17 B 1.1 .

[0065] (1) Take a batch of NdFeB waste (as above, 1000Kg after folding and solidification), and separate the obvious impurities by physical separation.

[0066] (2) Put the above-mentioned NdFeB waste into the hydrogenation basket, place it in a hydrogen crushing furnace with a dehydrogenation unit, and put it at room temperature, H 2 Press 4×10 5 Under the condition of Pa, hydrogen is introduced, and after the hydrogenation amount reaches more than 370g, it enters th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com