Nanometer calcium carbonate-polyvinyl chloride composite resin preparation method

A technology of polyvinyl chloride resin and nano-calcium carbonate, which is applied in the field of polymer materials, can solve problems such as complex process control, uneven dispersion of polyvinyl chloride, and impact on product performance, and achieve simple operation, no solid dust pollution, and improved polyvinyl chloride. Effect of properties of vinyl chloride products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

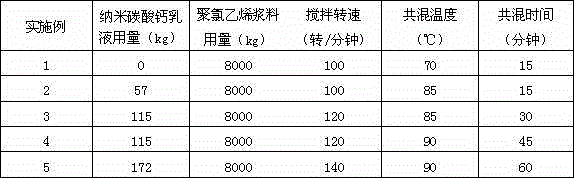

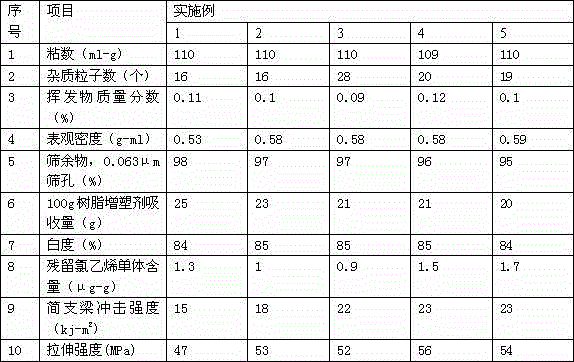

[0018] The present invention will be further described below in conjunction with the examples, without any limitation to the present invention.

[0019] The nano-calcium carbonate emulsion modified by titanate coupling agent (the solid content of nano-calcium carbonate is 35%) was stirred in the storage tank and preheated to 70°C for later use.

[0020] After the vinyl chloride polymerization reaction is over, the stripping tower strips the residues of vinyl chloride and ethylene dichloride in the polyvinyl chloride resin, and when starting to continuously feed into the slurry tank, open the outlet pipeline valve of the nano-calcium carbonate emulsion storage tank to feed Enter the nano calcium carbonate emulsion into the pre-mixing tank, pre-mix with the incoming polyvinyl chloride slurry (polyvinyl chloride content 25%), and then continuously enter the slurry tank, and control the blending temperature of the slurry tank to 70~ 100°C, pulse stirring for 10 to 90 minutes, then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com