Automatic line sander

A sanding machine and line technology, which is applied in the field of automatic line sanding machines, can solve the problems of polluting the environment, consumption of labor hours, and small cross-section.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

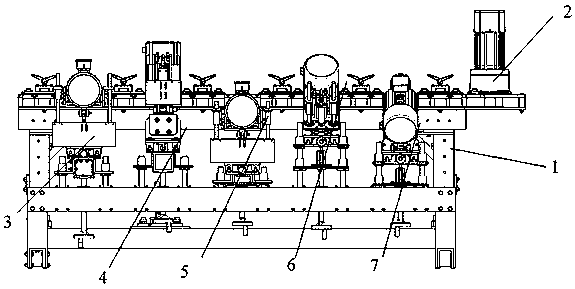

[0062] The automatic line sander includes a frame 1, a feeding drive unit 2 and a grinding head system; wherein the feeding driving unit 2 is installed on the frame 1; the grinding head system is installed on the grinding head mounting frame in the frame 1; the The grinding head system includes 5 grinding head mechanisms, which are divided into 2 horizontal grinding head mechanisms, 1 vertical grinding head mechanism and 2 inclined grinding head mechanisms.

[0063] The frame 1 also includes an adjustable lifting mechanism, a lifting operation mechanism for a feeding table, and the grinding head installation frame is connected with the adjustable lifting mechanism through bolts; 9. Feeding support fixed frame 10 and A screw mandrel 11, A screw mandrel 11 is connected with screw mandrel fixed belt seat bearing 8, screw mandrel fixed belt seat bearing 8 is connected with feeding support fixed frame 10, there are Slide rail 49, there are slide blocks 50 on both sides of the feedi...

Embodiment 2

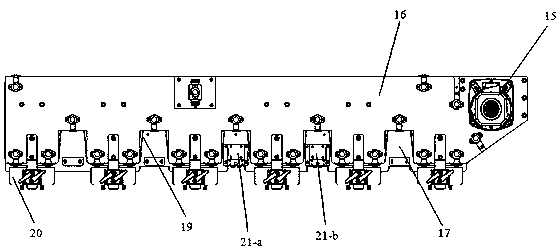

[0073] Automatic line sander, including frame 1, feeding drive unit 2 and grinding head system, frame 1 includes adjustable lifting mechanism, feeding platform lifting operating mechanism, timing belt 43 and grinding head mounting frame, adjustable lifting mechanism includes wire Rod fixed belt seat bearing 8, feeding platform lifting part 9, feeding support fixed frame 10, screw rod 11 are used to support and adjust the feeding drive unit 2, and the height of the feeding frame can be adjusted by operating the lifting hand wheel 42 to match different heights. End milling machine; grinding head mounting frame, including grinding head mounting frame column 13, gusset plate 12, grinding head mechanism installation profile 14, grinding head mounting frame column 13 is locked on the feeding support fixing frame 10 by bolts and passed through the angle bracket The plate 12 is fixed, and the grinding head mechanism installation profile 14 is locked on the column by bolts, which plays ...

Embodiment 3

[0079] The automatic line sander includes a frame 1, a feeding drive unit 2 and a grinding head system; wherein the feeding driving unit 2 is installed on the frame 1; the grinding head system is installed on the grinding head mounting frame in the frame 1; the The grinding head system includes 5 grinding head mechanisms, which are divided into 2 horizontal grinding head mechanisms, 1 vertical grinding head mechanism and 2 inclined grinding head mechanisms.

[0080] The frame 1 also includes an adjustable lifting mechanism, a lifting operation mechanism for a feeding table, and the grinding head installation frame is connected with the adjustable lifting mechanism through bolts; 9. Feeding support fixed frame 10 and A screw mandrel 11, A screw mandrel 11 is connected with screw mandrel fixed belt seat bearing 8, screw mandrel fixed belt seat bearing 8 is connected with feeding support fixed frame 10, there are Slide rail 49, there are slide blocks 50 on both sides of the feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com