A new welding device and method for soldering components on ceramic substrates

A welding device and ceramic substrate technology, applied in the direction of assembling printed circuits with electrical components, auxiliary devices, welding equipment, etc., can solve the problems that affect the welding quality and product performance, the operator's proficiency is greatly affected, and the welding consistency is poor. Achieve the effect of ensuring stability and reliability of solder joints, good operability, and reducing possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described in detail below in conjunction with accompanying drawing:

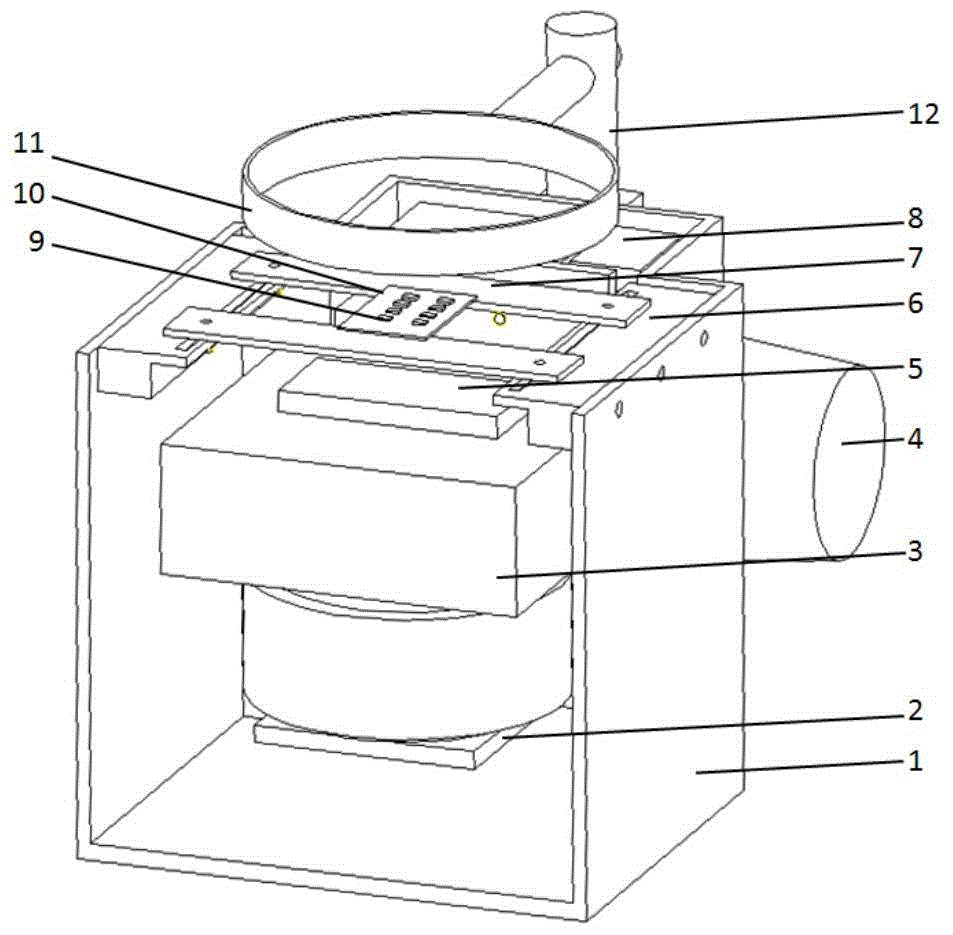

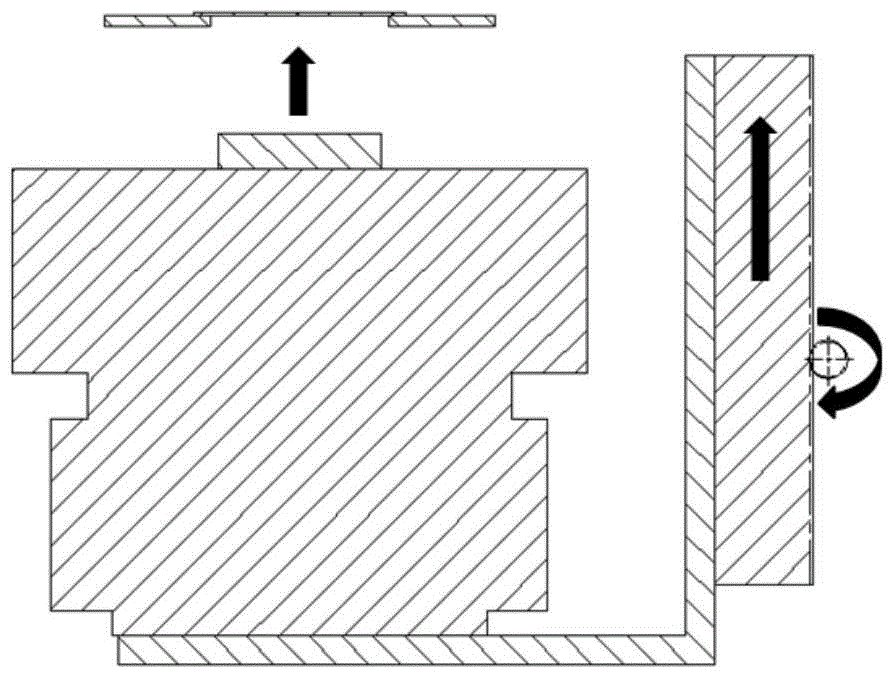

[0036] Such as figure 1 As shown, the device can be used to solder components on various ceramic substrates. Compared with traditional welding heating devices, this device has better welding quality and higher welding efficiency. A new welding device for soldering components on a ceramic substrate, the device is composed of four parts: a casing 1, a heating assembly, a lifting assembly, a carrying assembly and an observation assembly. The bottom of the shell is connected with the heating platform 3 of the heating assembly through the connecting plate 2 .

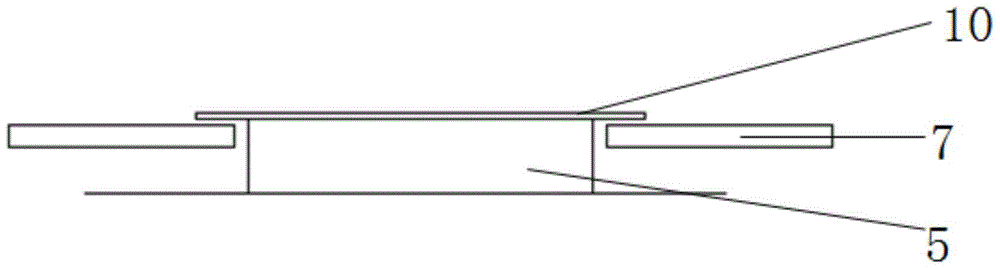

[0037]Heating component: the heating component is composed of a heating platform 3, a power supply and a heat transfer block 5, and the power supply is connected to the heating platform through wires to adjust the temperature of the heating platform. The current general-purpose heating table 3 is limited by the thermal co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com