Ivabradine hydrochloride osmotic pump controlled-release tablet and preparation method thereof

A controlled-release technology of ivabradine hydrochloride and osmotic pumps, which is applied in the fields of pharmaceutical formulations, medical preparations of non-active ingredients, cardiovascular system diseases, etc., can solve the problems that are not suitable for industrial production and the preparation process is complicated, and achieve Reduce the number of times of taking medicine, the process is mature, and the effect of good release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Tablet prescription:

[0032]

[0033] Coating prescription

[0034] composition

Dosage / g

Cellulose acetate

100

polyethylene glycol 4000

10

Appropriate amount

water

Appropriate amount

[0035] Preparation Process:

[0036] Pass the drug and polyoxyethylene in the prescription amount of the drug-containing layer through a 80-mesh sieve, add a lubricant and mix evenly; pass the prescription amount of polyoxyethylene, sodium chloride and magnesium stearate in the booster layer through a 80-mesh sieve, and add a lubricant Mix evenly, use the No. 8 punch twice to pressurize to get the tablet core. Cellulose acetate and polyethylene glycol were dissolved in acetone and distilled water respectively and mixed evenly, and the tablet core was coated with a coating pan with a weight gain of 6%. After coating, it was cured in an oven at 40°C for 12 hours. Then prepare and punch a 0.6mm diameter release h...

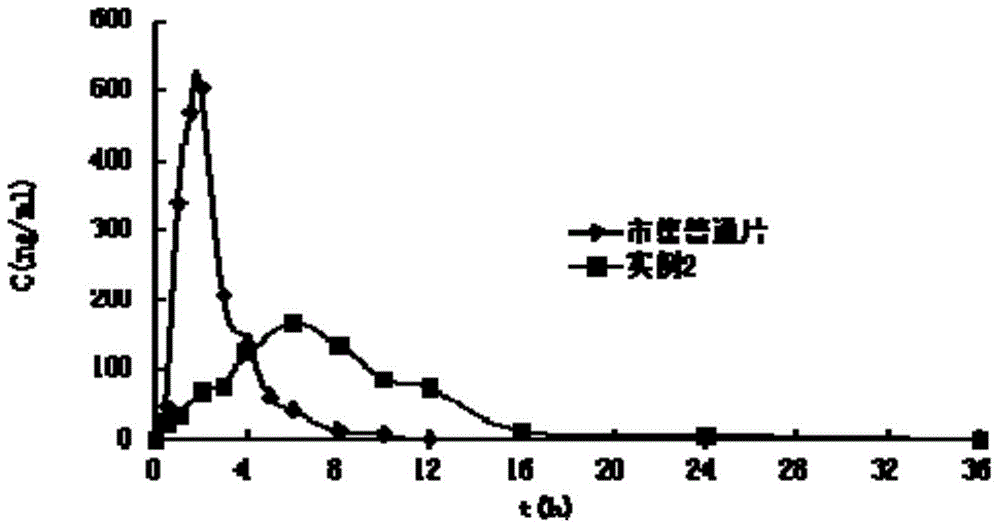

Embodiment 2

[0038] Tablet prescription:

[0039]

[0040] Coating film prescription:

[0041] composition

Dosage / g

100

polyethylene glycol 4000

12.5

Appropriate amount

Appropriate amount

[0042] Preparation Process:

[0043] Pass the drug, polyoxyethylene, and lactose in the prescription amount of the drug-containing layer through a 80-mesh sieve, add lubricant, and mix evenly; pass the prescription amount of polyoxyethylene and sodium chloride in the booster layer through an 80-mesh sieve, add lubricant and mix evenly , Use the No. 8 punch to pressurize twice to get the tablet core. Dissolve ethyl cellulose and polyethylene glycol in acetone and distilled water respectively and mix evenly, coat the tablet core with a coating pan, with a weight gain of 6%, and cure in an oven at 40°C for 12 hours after coating . Then prepare a 0.6mm diameter drug release hole on the drug-contai...

Embodiment 3

[0045]Tablet prescription:

[0046]

[0047] Coating film prescription:

[0048] composition

Dosage / g

Cellulose acetate

100

polyethylene glycol 4000

12.5

acetone

Appropriate amount

water

Appropriate amount

[0049] Preparation Process:

[0050] Pass the drug, polyoxyethylene, and mannitol in the prescription amount of the drug-containing layer through a 80-mesh sieve, add lubricant and mix evenly, pass the prescription amount of polyoxyethylene and sodium chloride in the booster layer through an 80-mesh sieve, add lubricant and mix evenly , Use the No. 8 punch to pressurize twice to get the tablet core. Cellulose acetate and polyethylene glycol were dissolved in acetone and distilled water respectively and mixed evenly, and the tablet core was coated with a coating pan, with a weight gain of 8%. After coating, it was cured in an oven at 40°C for 12 hours. Then prepare a 0.6mm diameter release hole on the si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com