Perovskite phase organic metal halide-based solar cell and manufacturing method thereof

A solar cell and organometallic technology, applied in the field of photovoltaics, can solve the problems of reducing semiconductor photovoltaic performance, small grain size of semiconductor layer, complicated process, etc., and achieve the effects of improving photovoltaic conversion efficiency, optimizing crystal growth, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

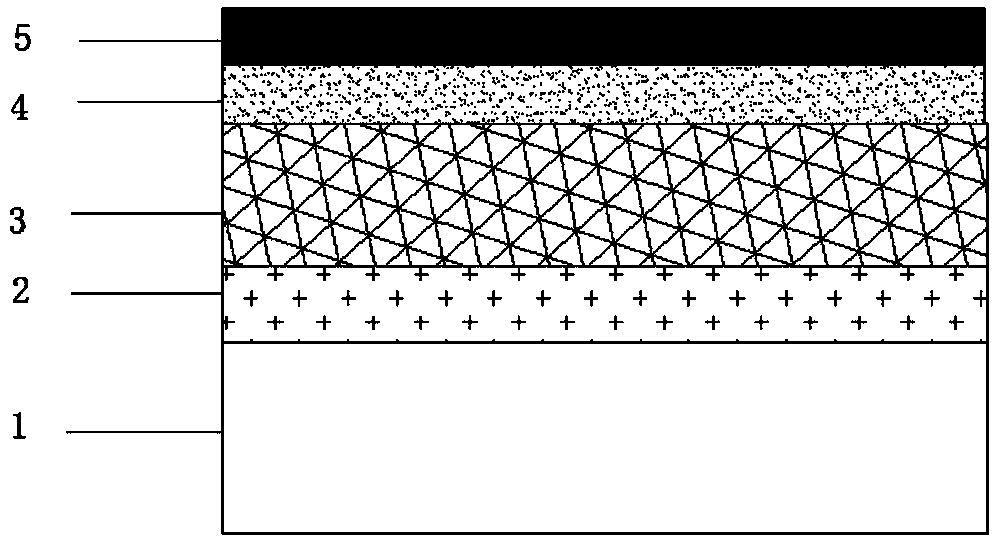

[0046] figure 1 It is a structural diagram of the solar cell of this embodiment, which includes a substrate 1 , an electron transport layer 2 , a perovskite phase organic metal halide semiconductor layer 3 , a hole transport layer 4 and a counter electrode layer 5 from bottom to top.

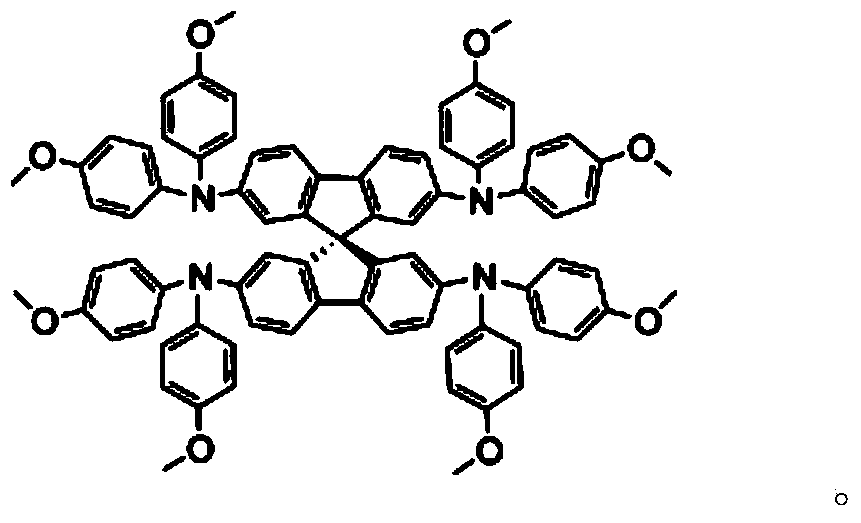

[0047] In this embodiment, the substrate 1 is indium tin oxide glass. The electron transport layer 2 is a dense titanium dioxide nano film with a surface roughness of less than 10nm and a thickness of 350nm. The thickness of the perovskite phase organic metal halide semiconductor layer 3 is 350nm, and the perovskite phase organic metal halide is CH 3 NH 3 PB 3-n Cl n , n is 0.05 in this embodiment. The hole transport layer 4 is made of Spiro-OMeTAD (2,2',7,7'-tetrakis[N,N-bis(4-methoxyphenyl)amino]-9,9'-spirobifluorene) , with a thickness of 350nm. The electrode layer 5 is made of Au and has a thickness of 60 nm.

[0048] The solar cell of this embodiment is prepared by the following ste...

Embodiment 2

[0062] The structure of the solar cell of this embodiment is the same as that of Example 1, and the preparation method is the same as that of Example 1, except that the step (S2) prepares the perovskite phase organic metal halide semiconductor layer on the electron transport layer, the step (S2) 2) General PbX 2 layer placed in CH 3 NH 3 PbX was soaked in 2-propanol solution of Y for 20s 2 The layer was soaked in 2-propanol solution for 1-2s to prevent PbX 2 layer for surface treatment. In actual operation, the substrate in step (1) is directly immersed in 2-propanol solution for 1-2 seconds.

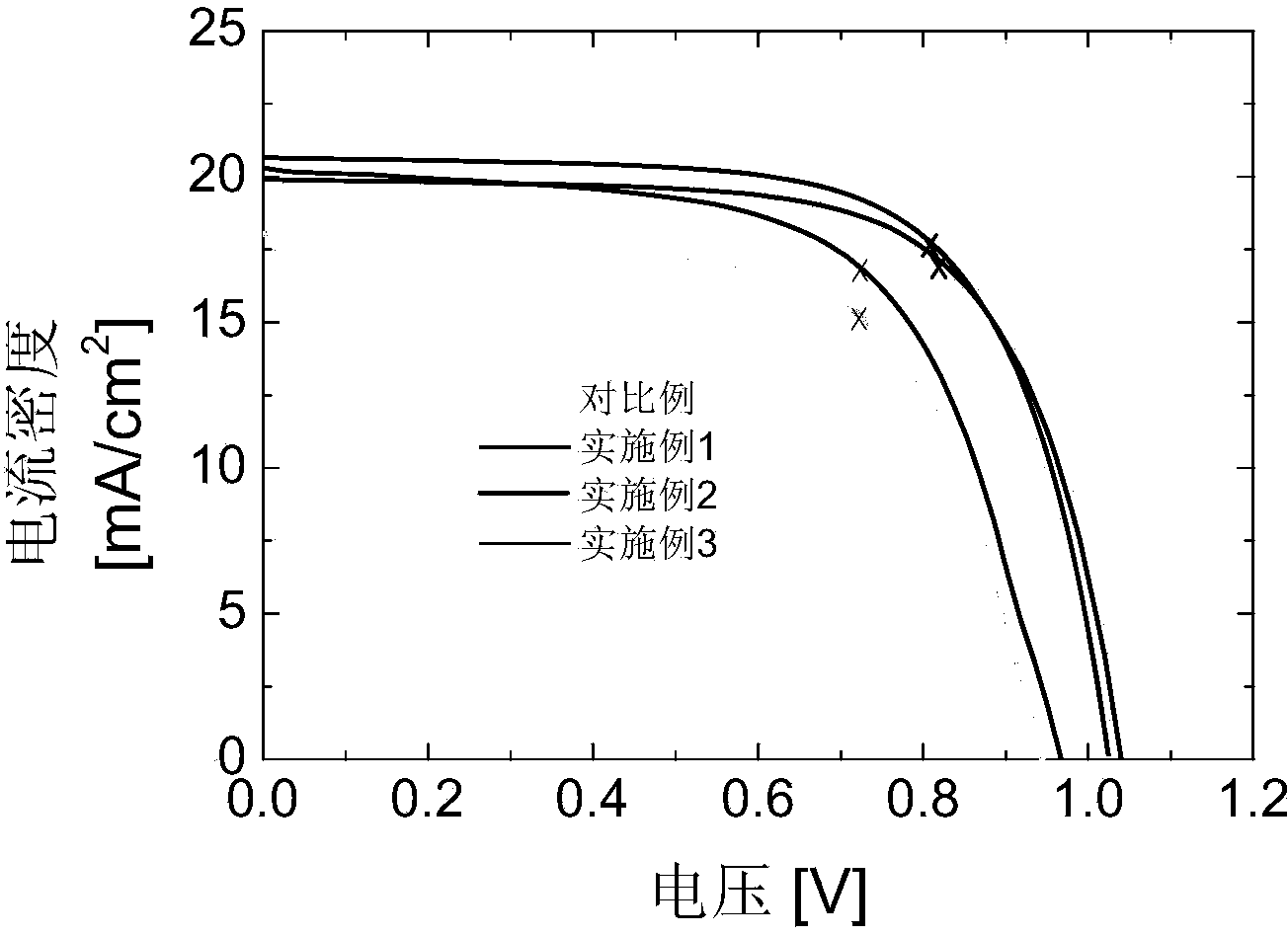

[0063] The solar cell of the present embodiment is at 100mW / cm 2 The current-voltage curve under AM1.5 sunlight is as follows figure 2 Shown in the corresponding curve of embodiment 2. Its volt-ampere performance curve is shown in Table 1.

Embodiment 3

[0065] The structure of the solar cell of this embodiment is the same as that of Example 1, and the preparation method is the same as that of Example 2, except that the PbX in step (1) 2 for PbCl 2 and PbI 2 mixture, and PbCl 2 and PbI 2 The molar ratio of the mixture is 1:9. CH in step (2) 3 NH 3 Y is CH 3 NH 3 I.

[0066] The solar cell of the present embodiment is at 100mW / cm 2The current-voltage curve under AM1.5 sunlight is as follows figure 2 Shown in the corresponding curve of embodiment 3. Its volt-ampere performance curve is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com