Super-high-efficiency lipid hydrolysis reactor and reaction process

An oil hydrolysis and ultra-efficient technology, applied in the chemical industry, can solve the problems of poor operation safety, large shortening space, and high equipment requirements, and achieve the effects of reducing energy consumption, reducing reaction temperature and pressure, and shortening reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

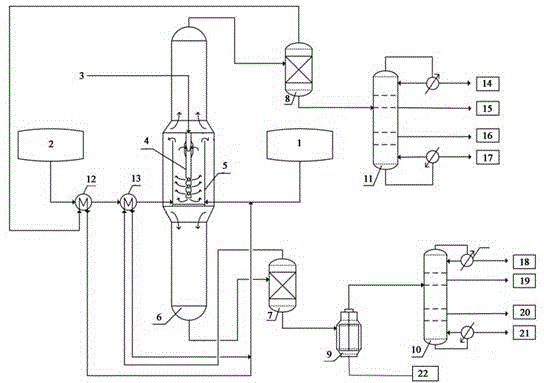

[0025] An ultra-high-efficiency oil hydrolysis reactor, including a raw oil oil storage tank 1, a water storage tank 2, a steam inlet pipe 3, a gas-liquid jet mixer 4, an inner cylinder 5, an outer cylinder 6, a glycerin flash tank 7, and a fatty acid flash tank Tank 8, scraper evaporator 9, glycerin rectification tower 10 and fatty acid rectification tower 11, wherein the gas-liquid jet mixer 4 is tubular, the bottom end is a helical tube, and the side wall of the helical tube has a plurality of small holes , The function of the gas-liquid jet mixer is to form a strong mixing action with the oil through the highly turbulent jet action of the high-pressure steam, so that the oil-water two phases that are difficult to be miscible can be highly emulsified and mixed and undergo a rapid hydrolysis reaction. The top of the gas-liquid jet mixer 4 is connected to the steam inlet pipe 3, and the bottom end enters the inner cylinder 5. The top of the inner cylinder 5 is open, and the bo...

Embodiment 2

[0029] A kind of reaction technique of ultra-efficient grease hydrolysis reactor according to claim 1, this technique comprises the following steps:

[0030] (1) After the water vapor ejected from the steam inlet pipe 3 passes through the gas-liquid jet mixer 4, it is injected into the inner cylinder 5 in a highly turbulent flow, which promotes the highly emulsified and hydrolyzed oil-water mixture in the inner cylinder 5. Specifically, after preheating the raw oil and water in the raw oil storage tank and water storage tank, they are respectively fed into the bottom of the inner cylinder of the reactor through a high-pressure pump, and the high-temperature and high-pressure water vapor is passed through the steam inlet pipe through the gas-liquid The jet mixer feeds into the reactor inner barrel. The water vapor is sprayed from the gas-liquid jet mixer at high speed to the bottom of the inner cylinder, and fully contacts with the reaction materials for efficient heat transfer...

Embodiment 3

[0035] This example illustrates ultra-efficient high-pressure continuous hydrolysis of palm oil.

[0036] (1) The hydrolysis reaction tower is 38 meters high, and the upper and lower sections are 1.2 meters in diameter. The axis of the main reaction section is fixed. The rectification section of the glycerol water rectification tower adopts a packed column with 40 theoretical plates, the stripping section adopts a valve tower with a plate number of 30; the fatty acid distillation adopts a packed column with a plate number of 80.

[0037] (2) The raw palm oil (containing 40% oleic acid; 10% linoleic acid; 45% palmitic acid and 5% stearic acid) is preheated and fed into the reactor inner cylinder 3 at a rate of 4t / h, while The hydrolyzed water is sent into the inner cylinder of the reactor at a rate of 2.2t / h, and the water vapor at 250°C and 4MPa is sprayed into the inner cylinder through the gas-liquid jet mixer at a rate of 2.5t / h, and the reactor starts to work at this time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com