Environmental-friendly modified calcium carbonate with delicate fragrance and preparation method thereof

A technology of calcium carbonate and light calcium carbonate, applied in chemical instruments and methods, addition of inorganic compounds, inorganic pigment treatment, etc., can solve problems such as defects, air bubbles, affecting material appearance, heat resistance and mechanical properties, and achieve good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

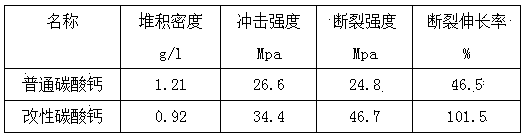

Image

Examples

Embodiment Construction

[0012] specific implementation plan

[0013] The present invention will be described in detail below through specific examples.

[0014] An environmentally friendly and fragrant modified calcium carbonate, prepared from the following raw materials in parts by weight (kg): light calcium carbonate 90, diatomaceous earth 3, dipotassium glycyrrhizinate 1, crushed lemongrass 3, crushed melon seed shell 2, dried Orange peel 2, crushed neem peel 2, fly ash 2, polylactic acid fiber 3, itaconate 4, glycidyl acrylate 4, mineral oil 3, modified titanium dioxide 3;

[0015] The modified titanium dioxide is made of the following raw materials in parts by weight (kg): nano-titanium dioxide 50, magnesium hydroxide 2, ethyl cellulose 4, n-butyl acrylate 5, quartz powder 3, polyisobutylene 3, alkyd resin 3 , terpineol 2, water 50; the preparation method is to first add n-butyl acrylate, nano-titanium dioxide, magnesium hydroxide, ethyl cellulose, and water to stir evenly to form a suspension,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com