Degradable UV curable resin and its preparation method and application in paper coating material

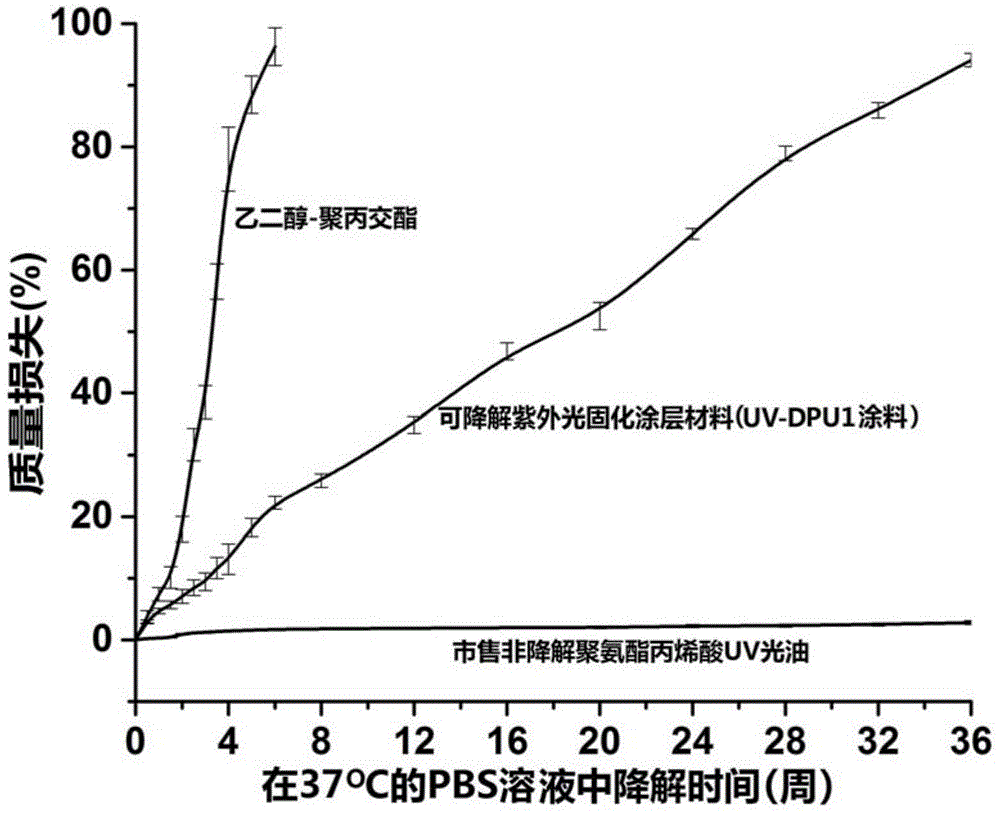

A technology of curing resin and ultraviolet light, which is applied in the direction of coating, polyurea/polyurethane coating, etc., can solve the problems of pollution, coating and printing waste that cannot be degraded and recycled by itself, and achieve high Young's modulus and good stress‐ Strain properties, effects of high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

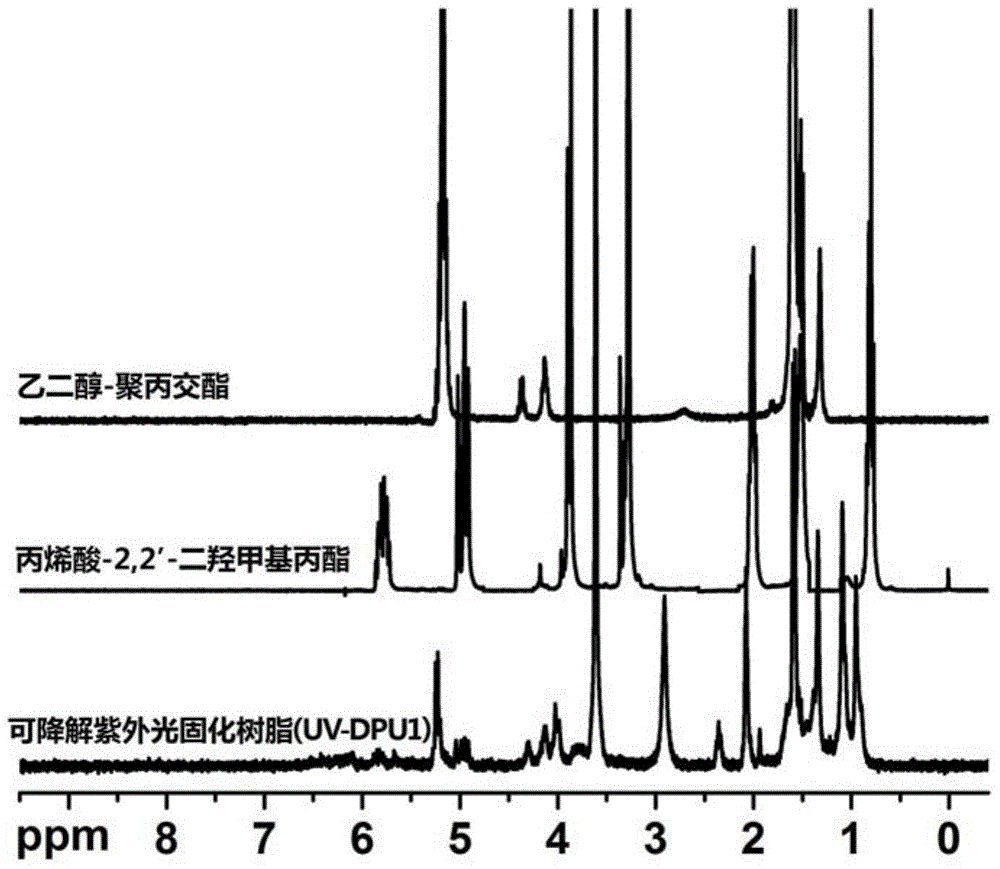

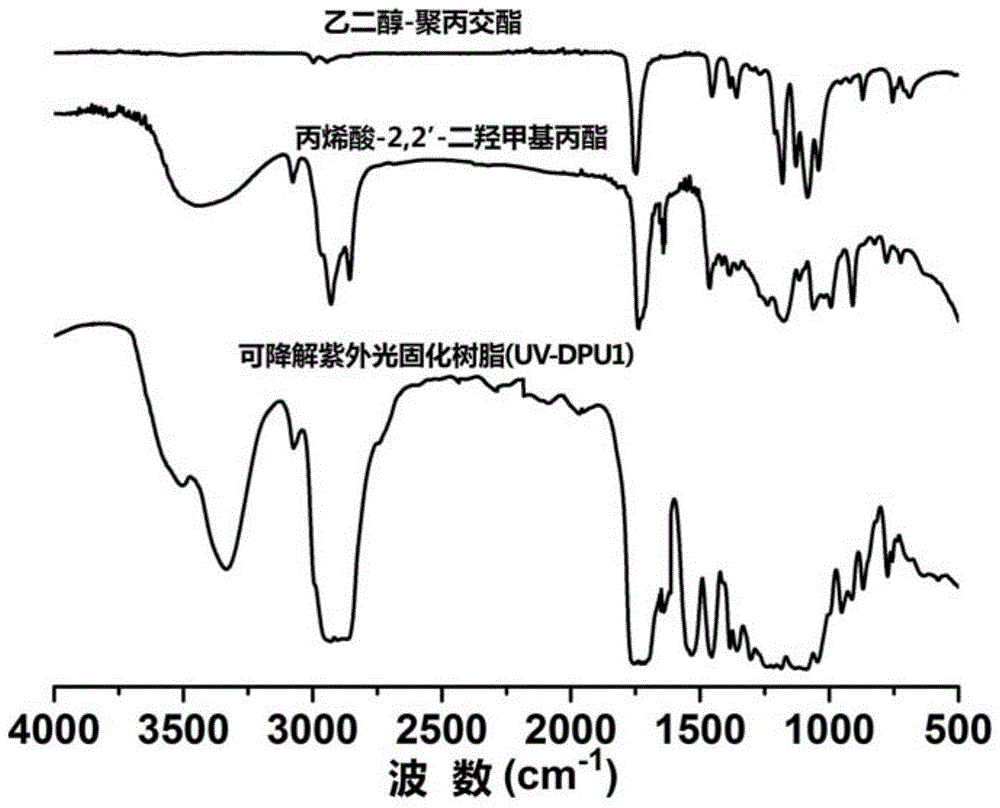

[0033] Prepare degradable UV-curable resin (UV-DPU1) and its coating materials (UV-DPU1 coating) as follows:

[0034] Step (1): Take 10 grams of ethylene glycol as an initiator, 0.1 grams of stannous octoate as a catalyst, and 75 grams of lactide, add them to a slender glass reaction tube with nitrogen, and then vacuumize. The glass at the mouth of the reaction tube was sintered and sealed with an alcohol torch flame; then the polymerization tube was reacted in an oil bath at 135°C for 18 hours. After cooling, the polymerization tube was broken to obtain a block polymer dissolved in chloroform, and then an excess of pure ethanol The polymer is precipitated from chloroform and dried under vacuum at room temperature to obtain degradable glycol-polylactide.

[0035] Step (2): Take 25 grams of trimethylolethane, 12 grams of acrylic acid, 0.01 grams of concentrated sulfuric acid as a catalyst, 0.005 grams of 2,5-di-tert-butyl hydroquinone as a polymerization inhibitor, and 80 grams of t...

Embodiment 2

[0044] Prepare the degradable ultraviolet curing resin (UV-DPU2) and its coating material (UV-DPU2 coating) as follows:

[0045] Step (1): Take 30 grams of 2-methyl-1,4-butanediol as an initiator, 0.065 grams of stannous octoate as a catalyst, and a mixed monomer of 75 grams of lactide and 25 grams of glycolide, and add them to The glass reaction tube with a slender neck is filled with nitrogen, and after vacuum treatment, the glass at the reaction tube mouth is sintered and sealed with an alcohol burner flame; then the reaction tube is reacted in an oil bath at 150°C for 24 hours, and then broken after cooling Polymerization tube, the obtained block polymer is dissolved in chloroform, and then the polymer is precipitated from chloroform with excess pure ethanol, and after vacuum drying at room temperature, the degradable 2-methyl-1,4-butanediol is obtained. Polylactide-glycolide.

[0046] Step (2): Take 45 grams of trimethylolpropane, add 20 grams of methacrylic acid, 0.02 grams ...

Embodiment 3

[0050] Prepare the degradable UV-curable resin (UV-DPU3) and its coating materials (UV-DPU3 coating) as follows:

[0051] Step (1): Take 20 grams of 1,4-butanediol as an initiator, 0.08 grams of stannous octoate as a catalyst, and 120 grams of lactide monomer, and add them to a glass reaction tube with a slender neck. After vacuuming, the glass at the mouth of the reaction tube was sintered and sealed with an alcohol torch flame; then the reaction tube was reacted in an oil bath at 130°C for 36 hours. After cooling, the polymer tube was broken and the bulk polymer was dissolved in chloroform. Then the polymer is precipitated from chloroform with an excess of pure ethanol, and after vacuum drying at room temperature, the degradable 1,4-butanediol-polylactide is obtained.

[0052] Step (2): Take 30 grams of trimethylolethane, add 15 grams of 3,3-dimethacrylic acid, 0.03 grams of concentrated sulfuric acid as a catalyst, and 0.005 grams of 2,5-di-tert-butyl hydroquinone as a catalyst....

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com