A kind of ramie and flax mixed mat and its processing technology

A processing technology, mat technology, applied in textiles and papermaking, heating/cooling fabrics, textiles, etc., can solve the problem that mats cannot achieve antibacterial, anti-odor and anti-ultraviolet, resource-consuming, etc., to eliminate bad odor, not easy to mold corrosion , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

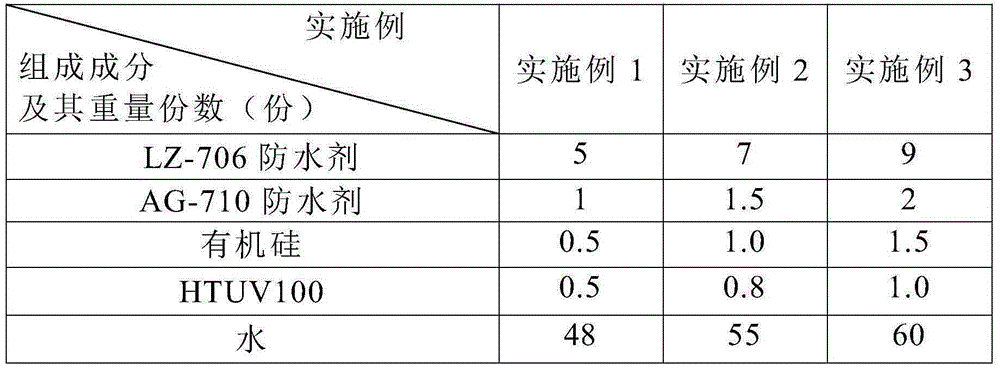

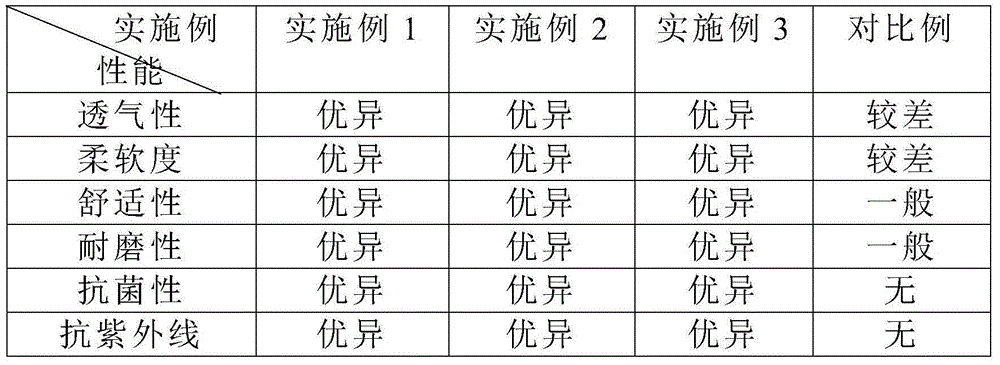

Embodiment 1

[0032] Sub-grass as weft treatment: firstly, the sub-grass is made into pulp by semi-chemical pulping method, and then processed by loose pulp, beating, glue and filling, etc., and then the prepared pulp is dehydrated, dried, calendered, etc. The finished paper is obtained through the papermaking process, and then the paper made of grass is cut into sheets, and finally the sheet-shaped paper is rolled into a rope-shaped paper as the weft thread.

[0033] Ramie as warp treatment: first chemically degumming the ramie to obtain ramie fibers, twisting the ramie fibers into threads, then soaking them in a solution of nano-silver antibacterial finishing agent with a pH of 5.0 and a concentration of 4.0%, and drying at 110°C for 1.0 Min later, it was woven as a warp thread to obtain the main body of the mat; the nano-silver antibacterial finishing agent was obtained by mixing nano-silver particles with a particle size of 25nm and polybutylacrylate emulsion at a mass ratio of 1:700 at ...

Embodiment 2

[0037] Sub-grass as weft thread treatment: Firstly, the sub-grass is made into pulp by semi-chemical pulping method, in which organic fluorine surfactant is added in the pulping process, and then the pulp is prepared by loose pulp, beating, glue and filling, and then the The prepared pulp is dehydrated, dried, and calendered to make paper products, and then the paper made of grass is cut into sheets, and finally the cotton thread is wrapped with a sheet of paper to form a rope-shaped paper. weft.

[0038] Ramie as warp treatment: first chemically degumming the ramie to obtain ramie fibers, twisting the ramie fibers into threads, then soaking them in a solution of nano-silver antibacterial finishing agent with a pH of 5.5 and a concentration of 5.0%, and drying at 120°C for 1.2 Min later, it was woven as a warp thread to obtain the main body of the mat; the nano-silver antibacterial finishing agent was obtained by mixing nano-silver particles with a particle size of 35nm and po...

Embodiment 3

[0042] Sub-grass as weft thread treatment: Firstly, the sub-grass is made into pulp by semi-chemical pulping method, in which organic fluorine surfactant is added in the pulping process, and then the pulp is prepared by loose pulp, beating, glue and filling, and then the The prepared pulp is dehydrated, dried, and calendered to make paper products, and then the paper made of grass is cut into sheets, and finally the sheet-shaped paper is rolled into rope-shaped paper as the weft.

[0043] Ramie as warp treatment: first chemically degumming the ramie to obtain ramie fibers, twisting the ramie fibers into threads, then soaking them in a solution of nano-silver antibacterial finishing agent with a pH of 6.5 and a concentration of 6.0%, and drying at 125°C for 1.5 Min later, it was woven as a warp thread to obtain the main body of the mat; the nano-silver antibacterial finishing agent was obtained by mixing nano-silver particles with a particle size of 40nm and polybutylacrylate em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com