Ceramic or enamel sterilization glaze material and preparation method and application thereof

A technology of enamel glaze and ceramics, which is applied in the field of ceramic sterilizing materials, can solve the problems of limited bactericidal ability improvement and useless bactericidal effect, and achieve the effects of strong sterilizing stability, environmentally friendly components, and guaranteed reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

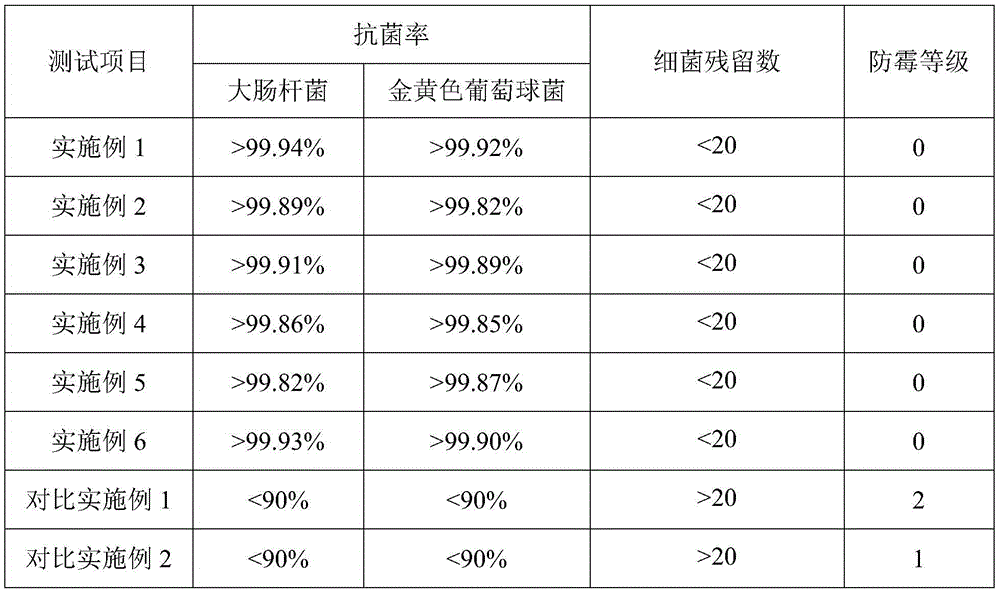

Embodiment 1

[0032] A ceramic or enamel sterilizing glaze material, which includes components and their weight percentages: 80% of the original liquid of ceramic glaze, 15% of silver powder, and 5% of copper oxide powder. The purity of the silver powder is not less than 99.99%. The particle size of the silver powder is 500 mesh, and the particle size of the copper oxide powder is 500 mesh. The above materials are mixed and ground for 30 hours with a high-speed ball mill, so that the powder particles are smaller than 200 nm, and a ceramic or enamel sterilization glaze material silver copper oxide composite glaze is prepared.

[0033] When applying the silver-copper oxide composite glaze obtained above to the ceramic surface as a top glaze, first apply the ordinary ceramic stock glaze as a base glaze, and cover the silver-copper oxide composite glaze obtained above as a surface glaze. It is sintered and melted on the surface of ceramic products at 1200°C to form a dense glaze of silver-copper ...

Embodiment 2

[0038] A ceramic or enamel sterilization glaze material, which includes components and their weight percentages: 90% of the original liquid of ceramic glaze, 5% of silver powder, and 5% of copper oxide powder. The purity of the silver powder is not less than 99.99%. The particle size of the silver powder is 800 mesh, and the particle size of the copper oxide powder is 500 mesh. The above materials are mixed and ground by a high-speed ball mill for 24 hours, so that the powder particles are less than 200 nm, and a ceramic or enamel sterilization glaze material silver copper oxide composite glaze is prepared.

[0039] When applying the silver-copper oxide composite glaze obtained above to the ceramic surface as a top glaze, first apply the ordinary ceramic stock glaze as a base glaze, and cover the silver-copper oxide composite glaze obtained above as a surface glaze. It is sintered and melted on the surface of ceramic products at 1200°C to form a dense glaze of silver-copper oxid...

Embodiment 3

[0041] A ceramic or enamel sterilizing glaze material, which includes components and their weight percentages: 80% of the original liquid of ceramic glaze, 6% of silver powder, and 14% of copper oxide powder. The purity of the silver powder is not less than 99.99%. The particle size of the silver powder is 500 mesh, and the particle size of the copper oxide powder is 800 mesh. The above materials are mixed and ground by a high-speed ball mill for 24 hours, so that the powder particles are less than 200 nm, and a ceramic or enamel sterilization glaze material silver copper oxide composite glaze is prepared.

[0042] When applying the silver-copper oxide composite glaze obtained above to the ceramic surface as a top glaze, first apply the ordinary ceramic stock glaze as a base glaze, and cover the silver-copper oxide composite glaze obtained above as a surface glaze. It is sintered and melted on the surface of ceramic products at 1200°C to form a dense glaze of silver-copper oxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com