Preparation method of mould proof heat treatment wood and application thereof

A kind of wood and anti-mildew technology, which is applied in the direction of wood heat treatment, wood treatment, impregnated wood, etc., can solve the problems of wood yellowing, etc., and achieve the effect of inhibiting mold and good anti-mildew control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

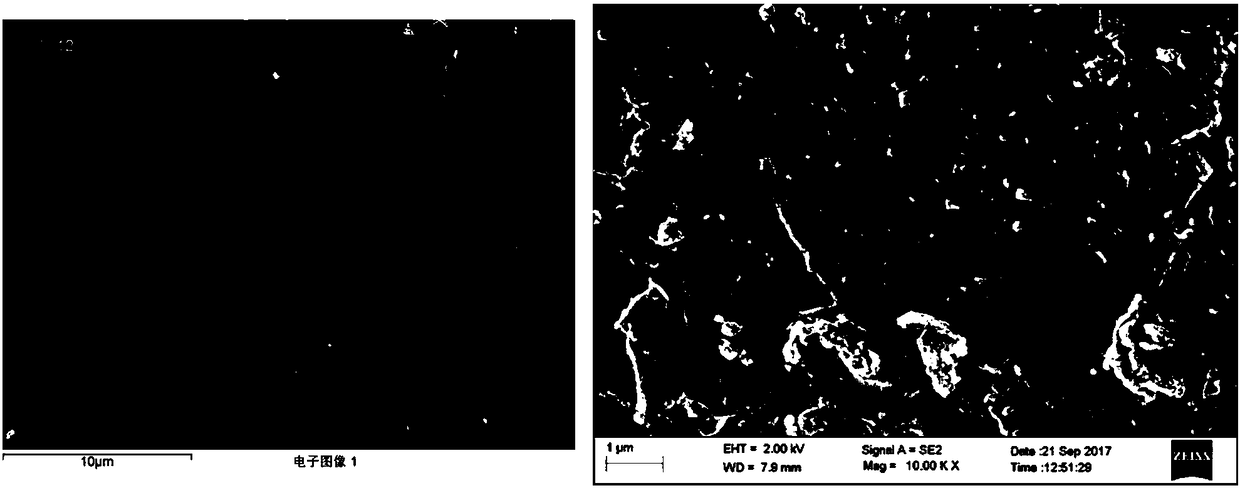

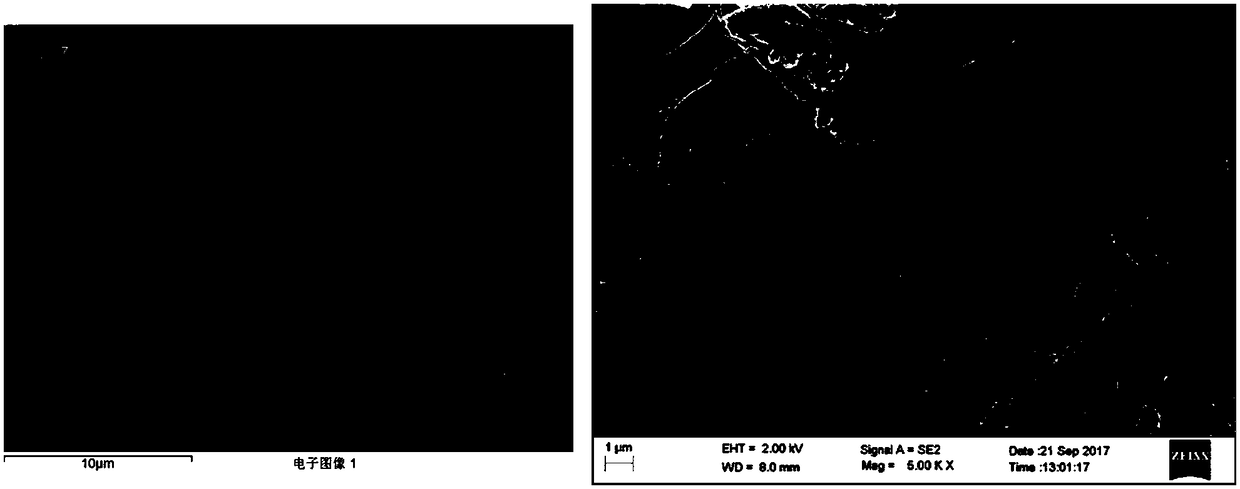

Image

Examples

Embodiment 1

[0041] Preparation of copper-containing compound impregnating solution Dissolve 349.2 g of copper hydroxide in 755.2 g of diethanolamine, add 537.4 g of water to form a cuproammonia solution, and then mix in 358.2 g of PEG200 to form a copper-containing compound impregnating solution. The mass proportions of diethanolamine, copper hydroxide, PEG200 and water are 37.76%, 17.46%, 17.91% and 26.87%.

[0042] Both the dipping solution treatment and the high temperature heat treatment are operated according to the following steps:

[0043] (1) Pretreatment of wood

[0044] (1) Take 25-year-old masson pine wood sapwood to prepare wood samples, the size of which is 50mm (longitudinal) x 20 (chord) mm x 5mm (radial);

[0045] (2) Before the vacuum pressure treatment, first place the wood sample in an oven at 60°C until the quality is constant; then immerse the wood sample in the copper-containing compound impregnation solution, keep the vacuum at -0.09MPa for 30min, and then Take it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com