A method for manufacturing ultra-high voltage and fast recovery glass-encapsulated diodes above 13,000 volts

A glass encapsulation and manufacturing method technology, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, and electrical solid-state devices, etc., can solve the problems of large forward power loss, unsuitable for mass production, and large volume of silicon stacks, and can reduce the Package volume, high long-term working reliability, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0048] to combine figure 1 The flow chart of the present invention illustrates the method step of the present invention:

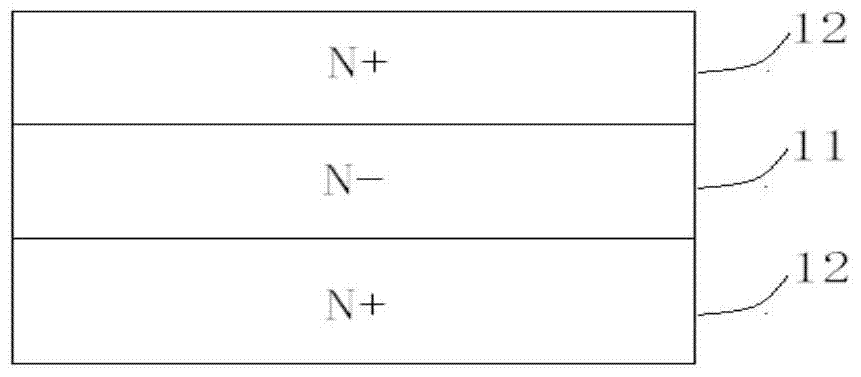

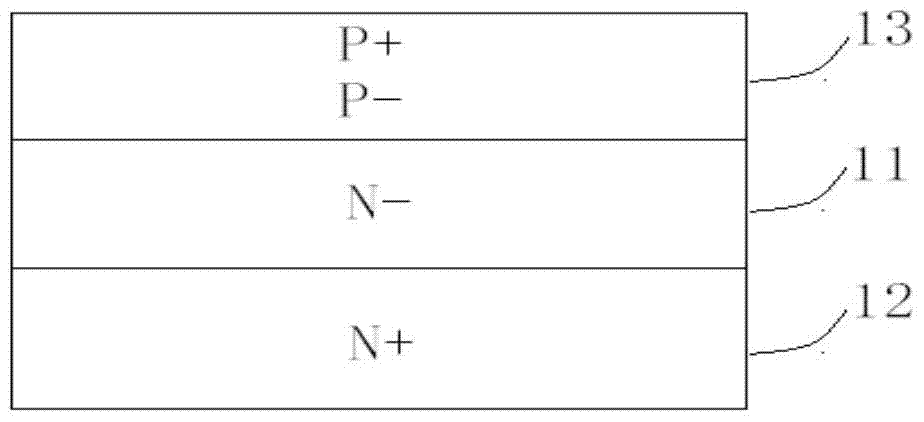

[0049] Step S101, providing a semiconductor substrate, the semiconductor substrate is an N-type semiconductor silicon material, and different material resistivities can be selected according to different reverse voltages. In order to ensure a reverse voltage above 13,000 volts, the voltage of a single tube must be at least Above 1500V, the resistivity of the material should be selected at 40-50Ω.cm, and the thickness of the N-type substrate should be 500μm; see figure 2 N-type silicon material layer 11;

[0050] Step S102, doping N on the N-type semiconductor substrate + Type impurities (phosphorous oxides, suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com