Food waste oil-water centrifugal separation device

A technology for centrifugal separation and kitchen waste, which is applied in the direction of centrifugal separation of water/sewage treatment, liquid separation, separation methods, etc. It can solve the problems of large equipment investment, difficulty in dredging, inconvenient oil extraction, etc., and achieves high separation efficiency and automation High-level, simple-to-run effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

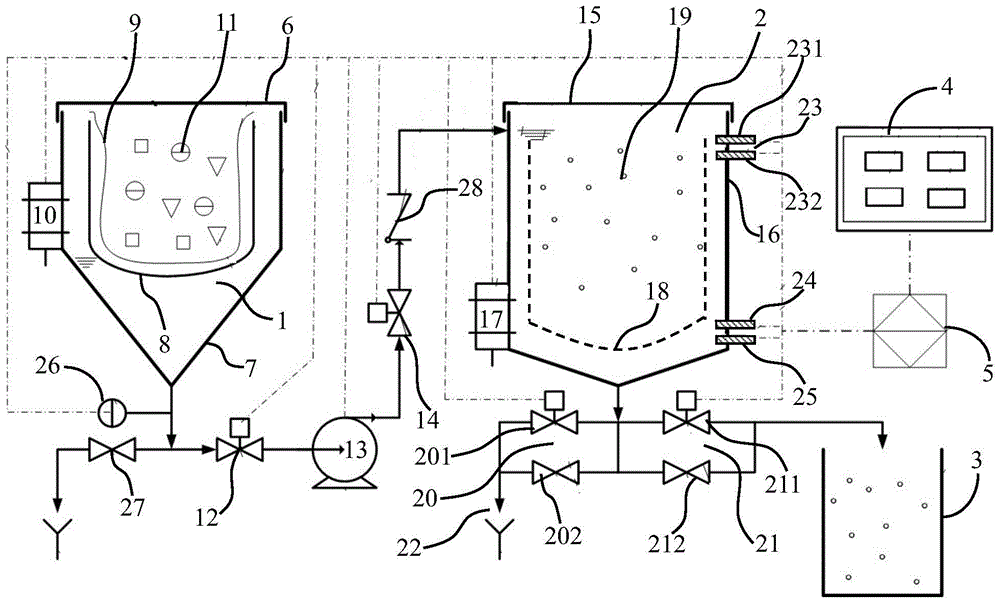

[0022] Embodiment: a kitchen garbage oil-water centrifugal separation device, comprising a solid-liquid separation centrifuge 1, an oil-water separation centrifuge 2, an oil storage tank 3, a control box 4 and a PLC controller 5, and the solid-liquid separation centrifuge 1 includes The first machine cover 6, the first box body 7, the stainless steel mesh liner 8, the garbage collection bag 9 and the first motor 10, the garbage collection bag 9 is used to place kitchen waste 11, and the garbage collection bag 9 is located Inside the stainless steel mesh liner 8, the stainless steel mesh liner 8 is located in the first box body 7, the first motor 10 is connected to the stainless steel mesh liner 8 and drives the stainless steel mesh liner 8 under working conditions Rotate, the first machine cover 6 is installed on the top surface of the first box body 7, the bottom of the first box body 7 is connected to the liquid inlet valve 12 and one end of the lift pump 13 in turn through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com