Low-cost lead-free soldering flux alloy powder for LED (light emitting diode) and preparation method of alloy powder

A lead-free solder alloy, low-cost technology, applied in the field of SnZnBiCu-X lead-free solder alloy powder and its preparation for LED, low-cost lead-free solder alloy powder and its preparation field, can solve the problem of poor oxidation resistance, corrosion resistance, and constraints The development of the LED industry, the increase in raw material costs and other issues, achieve the effect of smooth surface, improved atomization efficiency, and stable particle size distribution range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

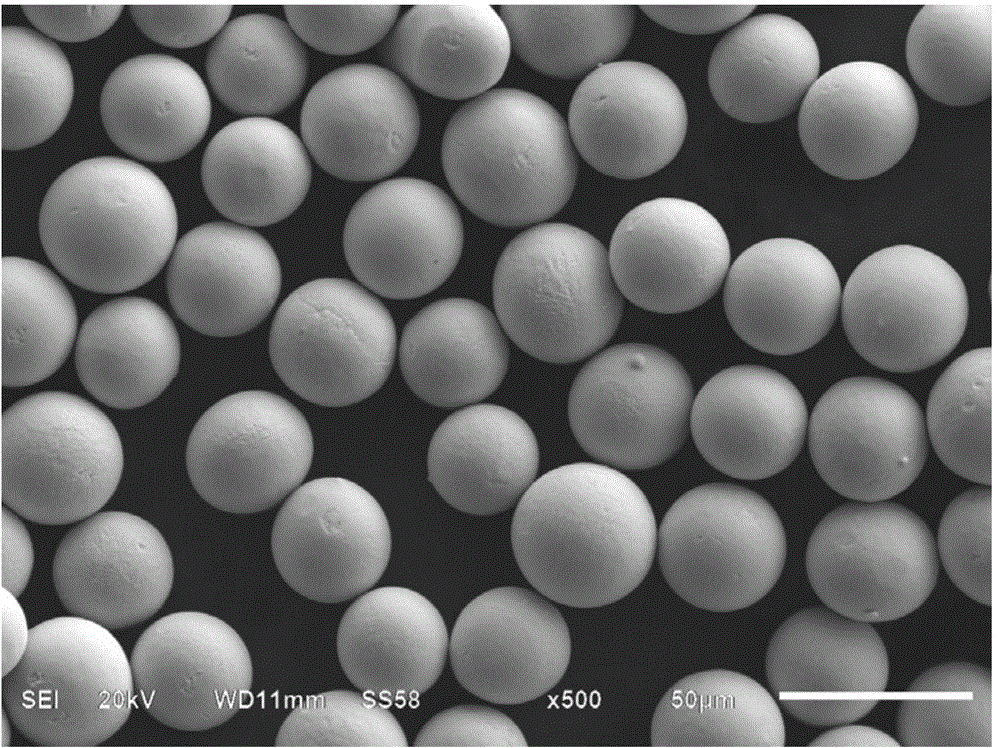

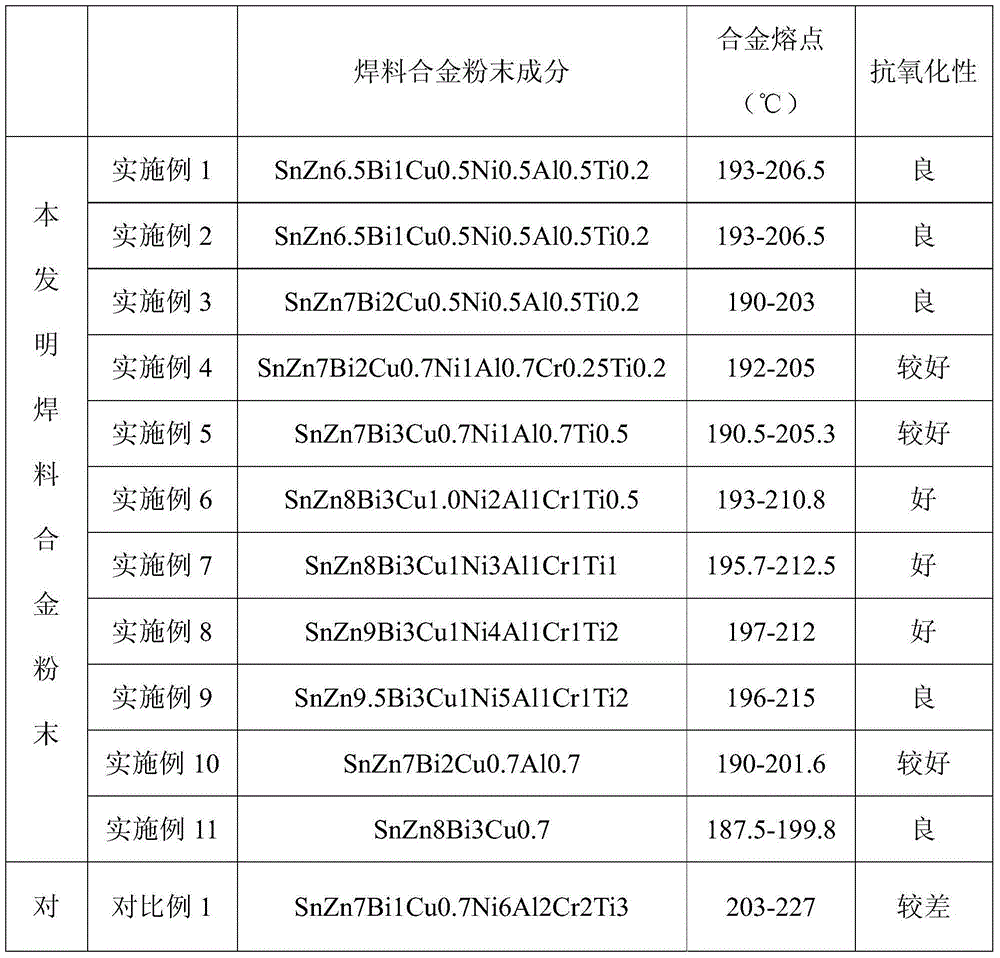

[0031] A kind of lead-free solder alloy powder for LED, by weight percentage, this lead-free solder alloy powder comprises: Zn 6.5%, Bi 1.0%, Cu 0.5%, Ni 0.5%, Al 0.5%, Ti 0.2%, the rest is Sn , the lead-free solder alloy powder is spherical, and its shape is as follows figure 1 As shown, its oxygen content is lower than 75ppm, its particle size distribution range is 25-35μm, the average particle size is 28μm, and its melting point is 193-206.5°C. The method for preparing the lead-free solder alloy powder for LED comprises the following steps:

[0032] 1) The metal Sn, Sn-10Cu, Sn-5Ni, Sn-6Al, Zn-3Ti master alloy and metal Bi are proportioned according to the weight percentage, and put into the induction furnace crucible as raw materials.

[0033] 2) Pre-vacuumize the smelting chamber and atomization chamber to 1×10 -2 Pa, and then filled with an inert protective gas (argon or nitrogen), the pressure of the melting chamber is 0.5MPa.

[0034] 3) The raw material is heated a...

Embodiment 2

[0038]A kind of lead-free solder alloy powder for LED, by weight percentage, this lead-free solder alloy powder comprises: Zn 6.5%, Bi 1.0%, Cu 0.5%, Ni 0.5%, Al 0.5%, Ti 0.2%, the rest is Sn , the lead-free solder alloy powder is spherical, its oxygen content is lower than 75ppm, its particle size is 20-38μm, its average particle size is 28.5μm, and its melting point is 193-206.5°C. The method for preparing the lead-free solder alloy powder for LED comprises the following steps:

[0039] 1) The metal Sn, Sn-10Cu, Sn-5Ni, Sn-6Al, Zn-3Ti master alloy and metal Bi are proportioned according to the weight percentage, and put into the induction furnace crucible as raw materials.

[0040] 2) Pre-vacuumize the smelting chamber and atomization chamber to 1×10 -1 Pa, and then filled with inert protective gas, the pressure of the smelting chamber is 0.5MPa.

[0041] 3) Induction coils are used to heat and melt the raw materials.

[0042] 4) Pass high-pressure atomizing gas into the ...

Embodiment 3

[0045] A kind of lead-free solder alloy powder for LED, by weight percentage, this lead-free solder alloy powder comprises: Zn 7.0%, Bi 2.0%, Cu 0.5%, Ni 0.5%, Al 0.5%, Ti 0.2%, the rest is Sn , the lead-free solder alloy powder is spherical, its oxygen content is lower than 78ppm, its particle size is 23-37μm, its average particle size is 30μm, and its melting point is 190-203°C. The method for preparing the lead-free solder alloy powder for LED comprises the following steps:

[0046] 1) The metal Sn, Sn-10Cu, Sn-5Ni, Sn-6Al, Zn-3Ti master alloy and metal Bi are proportioned according to the weight percentage, and put into the induction furnace crucible as raw materials.

[0047] 2) Pre-vacuumize the smelting chamber and atomization chamber to 1×10 -2 Pa, and then filled with inert protective gas, the pressure of the smelting chamber is 0.5MPa.

[0048] 3) Induction coils are used to heat and melt the raw materials.

[0049] 4) Pass high-pressure atomizing gas into the noz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen content | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com