Preparation method of recycled polyester

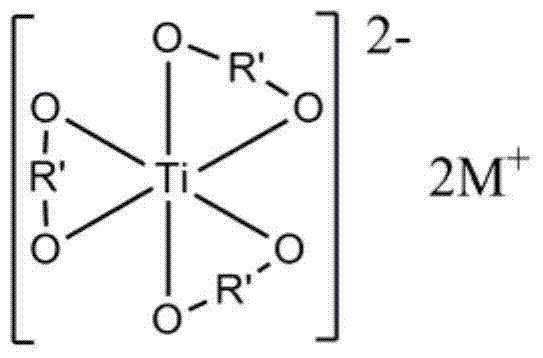

A technology for regenerating polyesters and polyesters, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, plastic recycling, etc., can solve the problems of catalyst heterogeneity and low catalytic efficiency, and achieve high efficiency and The effect of directional catalytic activity, increasing storage cost, improving homogeneity and ligand exchange activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

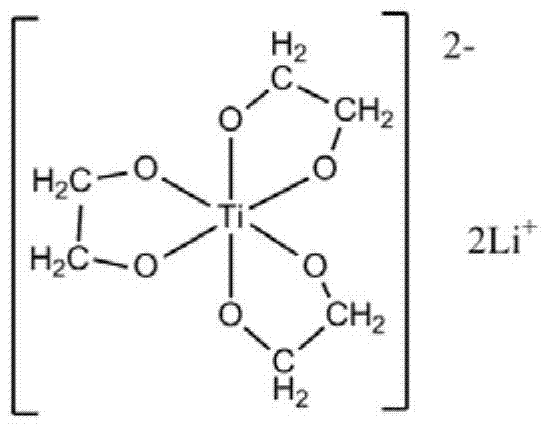

[0050] At first carry out the preparation of ethylene glycol lithium titanate, it comprises the following steps:

[0051] a) Uniformly mix tetraethyl titanate with ethylene glycol at 50°C under nitrogen protection, the molar ratio of tetraethyl titanate to ethylene glycol is 1:100;

[0052] b) Add lithium hydroxide, the molar ratio of lithium hydroxide to tetraethyl titanate is 2.05:1, continue to stir until the reaction system is a uniform and transparent liquid, then raise the reaction temperature to 180°C;

[0053] c) During the reaction process, reflux ethylene glycol and exclude the low-boiling ethanol and water generated by the reaction. The reaction time is 3 hours. Completely evaporate the ethylene glycol in the system, and completely evaporate the dihydric alcohol in the system to obtain a white solid, which is recrystallized three times with ethanol-chloroform to obtain a colorless crystal, which is to obtain ethylene glycol lithium titanate;

[0054] The structural...

Embodiment 2

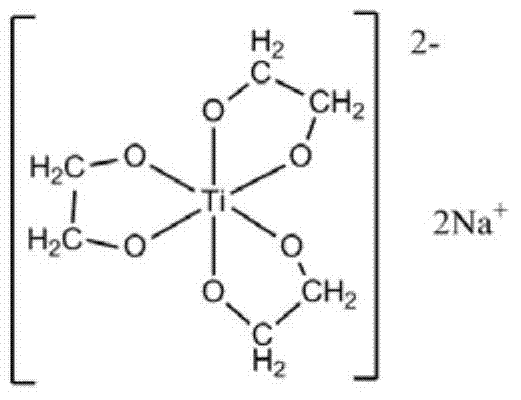

[0065] At first carry out the preparation of ethylene glycol sodium titanate, it may further comprise the steps:

[0066] a) Uniformly mix tetra-n-butyl titanate with ethylene glycol at 150°C under nitrogen protection, the molar ratio of tetra-n-butyl titanate to ethylene glycol is 1:50;

[0067] b) Add sodium hydroxide, the molar ratio of sodium hydroxide to tetra-n-butyl titanate is 2.03:1, and continue to stir until the reaction system becomes a uniform and transparent liquid, then raise the reaction temperature to 210°C;

[0068] c) During the reaction process, reflux ethylene glycol and exclude the low-boiling n-butanol and water generated by the reaction. The reaction time is 2 hours. Completely evaporate the ethylene glycol in the system and completely evaporate the dihydric alcohol in the system to obtain a white solid, which is recrystallized three times with ethanol-chloroform to obtain a colorless crystal, which is to obtain ethylene glycol sodium titanate;

[0069...

Embodiment 3

[0080] At first carry out the preparation of propylene glycol potassium titanate, it may further comprise the steps:

[0081] a) Uniformly mix tetraisopropyl titanate with 1,2-propanediol at 100°C under nitrogen protection conditions, the molar ratio of tetraisopropyl titanate to 1,2-propanediol is 1:80;

[0082] b) Add potassium hydroxide, the molar ratio of potassium hydroxide to tetraisopropyl titanate is 2.02:1, continue to stir until the reaction system is a uniform and transparent liquid, then raise the reaction temperature to 200°C;

[0083] c) During the reaction, reflux 1,2-propanediol and exclude the low-boiling isopropanol and water generated by the reaction. The reaction time is 4 hours. After the reaction is completed, the temperature is 200 ° C, and the reaction system pressure is 0.7 atm, 1 min Completely evaporate the ethylene glycol in the system, and completely evaporate the glycol in the system to obtain a light yellow solid, which is recrystallized three ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com