A strain of Enterococcus faecalis hew-a131 and its application

A HEW-A131, Enterococcus faecalis technology, applied in the application, bacteria, microorganisms and other directions, can solve the heat resistance of Enterococcus faecalis, acid and alkali fermentation performance, antibacterial performance is not ideal, can not meet the needs of industrialization, Obstructing the widespread use of probiotics, etc., to achieve a wide range of acid and alkali resistance, improve animal production performance, and improve intestinal performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1 Isolation, screening, identification and storage of Enterococcus faecalis HEW-A131

[0045] 1. Isolation and purification of lactic acid bacteria:

[0046] Under sterile conditions, collect 1 g of cecal intestinal contents of healthy cage-grown adult laying hens, put them in a centrifuge tube filled with 4.5 mL of sterile saline, shake and mix well, and then draw 0.5 mL of the mixed solution into a 4.5 mL centrifuge tube. mL of sterile saline in a centrifuge tube, this dilution is 10 -2 , repeat the above process to do 10-fold serial dilution, to 10 -6 Dilution concentration, choose 10 -4 ~10 -6 For three dilutions, draw 0.1mL and spread it on the Enterococcus medium (Enterococcus solid medium) plate, and adopt anaerobic culture method (5% CO2) after the plate is coated. 2 ), after culturing the coated plate at 35°C for 24 hours, use an inoculation loop to pick out colonies with blue-black rings and different shapes on the MRS solid medium plate for streak...

Embodiment 2

[0069] Example 2 Preparation of Enterococcus faecalis HEW-A131 fermentation broth

[0070] Get Enterococcus faecalis HEW-A131 (preservation number is CGMCC No.9353) seed solution (viable bacteria concentration is 10 9 CFU / mL) 3mL, inoculated in 300mL medium for shake flask fermentation culture, the fermentation temperature was 35°C, pH 7.0, 180r / min, and the fermentation time was 7h.

[0071] Among them, the shake flask fermentation medium is composed of the following components: 2.5% sucrose, 1.8% soybean peptone, 0.4% yeast extract, MgSO 4 ·7H 2 O0.2%, MnSO 4 4H 2 O0.045%, NaCl 0.2%, Diammonium Citrate 0.2%, CaCO 3 0.06%, the balance is water, pH7.0±0.2.

[0072] After the shake flask fermentation, carry out the fermenter pilot test, take 0.30L shake flask fermentation seed liquid and inoculate it into a 50L fermenter, with a liquid volume of 30L, a fermentation temperature of 35°C, a pH value of 7.0, and a stirring speed of 110r / min. Time 8h. The composition of the m...

Embodiment 3

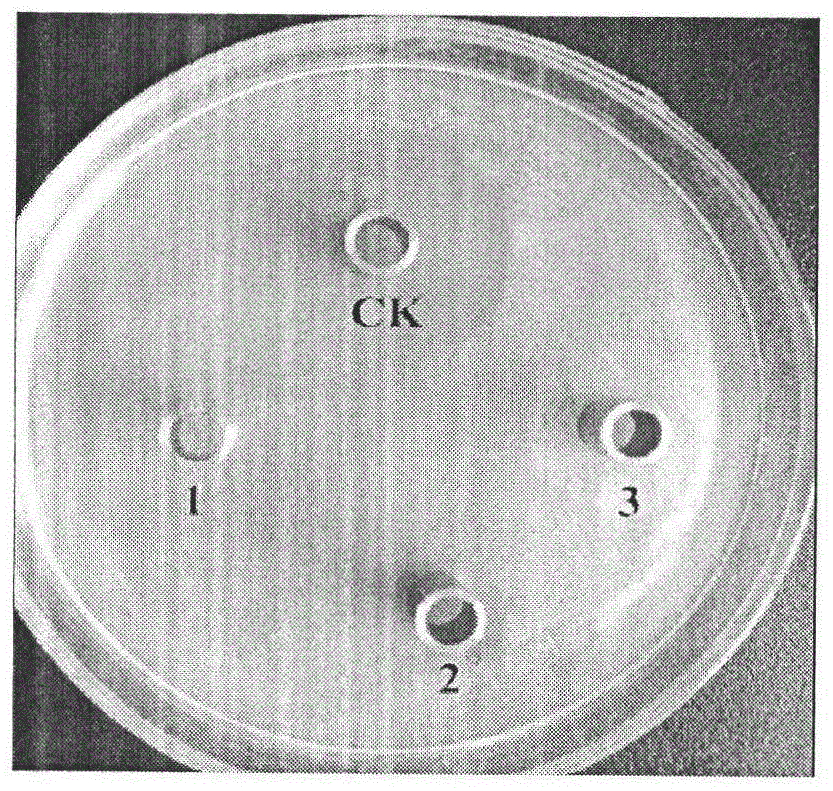

[0074] Example 3 Probiotic verification of Enterococcus faecalis HEW-A131

[0075] On the aseptic operation table, pathogenic bacteria (E. coli, Staphylococcus aureus, Salmonella, Klebsiella pneumoniae, Shigella, Veillonella, Pseudomonas aeruginosa, Aeromonas hydrophila, and more Killer Pasteurella) at a concentration of 10 9 Mix 50 mL of the CFU / mLd bacterial suspension with an equal volume of NA medium (after sterilization) cooled to 45°C to prepare a NA plate of pathogenic bacteria of about 4 mm, and place a sterilized Oxford cup (inside diameter of 6 mm, outside 10mm high circular small tube, the two ends of the tube should be smooth) placed on the medium, gently pressurized to make it contact with the medium without gaps, after a few minutes, drop 200 μL of the preserved The fermented liquid prepared in embodiment 2, do not make it overflow, cultivate 28h at 35 ℃, then measure the diameter of the inhibition zone. Each experiment was repeated three times, and the average...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com