Novel synthesis process of environment-friendly heavy metal vat golden orange G

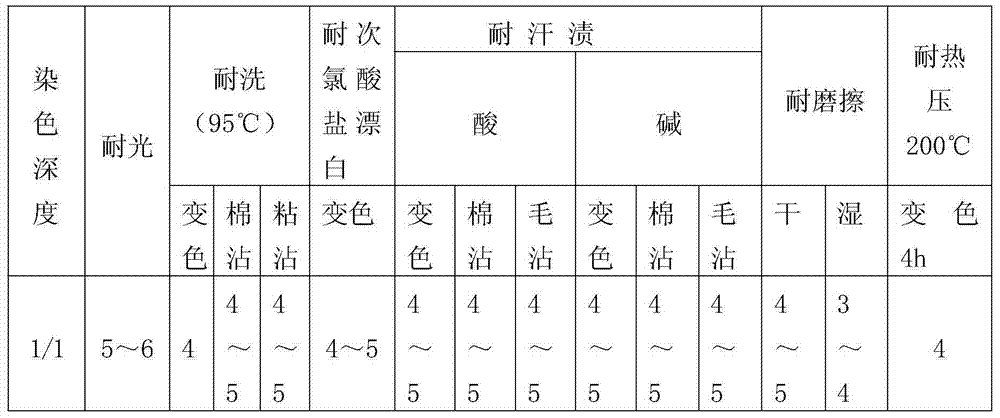

A low-heavy metal, environment-friendly technology, applied in the field of dyes, can solve the problems of poor environmental performance of heavy metal content, non-conformity with national sustainable development, traditional process pollution, etc., to reduce treatment costs, high product yield, and broad development space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

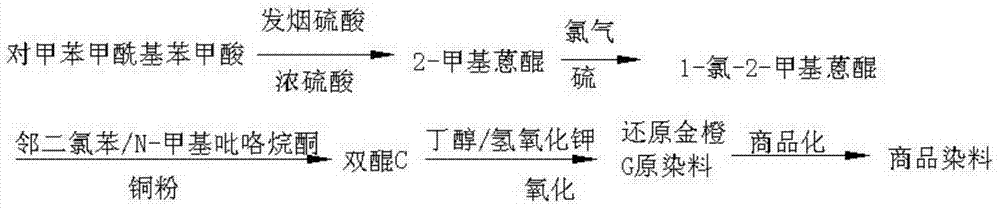

Method used

Image

Examples

Embodiment 1

[0024] (1) Chlorination reaction: in parts by weight, adding p-toluoylbenzoic acid 300kg into 100~108% oleum 800L, 200L parts of vitriol oil in 100°C for dehydration at 100°C with an acidity of 300kg was incubated for 1 hour to generate 2 -Methylanthraquinone; then under the action of 1kg of sulfur, chlorine gas was introduced at a temperature of -5°C and a pressure of 0.01MPa for reaction, and after being kept warm for 1 hour, washed and dried to obtain 1-chloro-2-methylanthraquinone;

[0025] (2) Condensation reaction: In parts by weight, add 400kg of 1-chloro-2-methylanthraquinone obtained in step (1) into the condensation pot, heat to 100°C, dehydrate for 1 hour, then add o-dichlorobenzene 30kg, 60kg of N-methylpyrrolidone, heated to 175°C to melt all the materials; slowly add 150kg of copper powder under stirring, then slowly raise the temperature to 170°C, control the pressure at 0.1MPa, keep warm for 11 hours, add 1000L of Chlorobenzene, cooled to 60°C, filtered, and wa...

Embodiment 2

[0028] (1) Chlorination reaction: in parts by weight, adding 550 kg of p-toluoylbenzoic acid into 108% fuming sulfuric acid 1500L and 700L concentrated sulfuric acid is dehydrated at 130° C. for 1.5 hours to generate 2-methyl Anthraquinone; then under the action of 5kg of sulfur, chlorine gas was introduced at a temperature of 20°C and a pressure of 0.05MPa for reaction, and after 1.5 hours of heat preservation, it was washed and dried to obtain 1-chloro-2-methylanthraquinone;

[0029] (2) Condensation reaction: In parts by weight, add 600kg of 1-chloro-2-methylanthraquinone obtained in step (1) into the condensation pot, heat to 106°C, dehydrate for 1.5 hours, then add o-dichlorobenzene 50kg, 100kg of N-methylpyrrolidone, heated to 190°C to melt all the materials; slowly add 300kg of copper powder under stirring, then slowly raise the temperature to 260°C, control the pressure at 0.25MPa, after 12 hours of heat preservation, add 1000L of Chlorobenzene, cooled to 70°C, filtere...

Embodiment 3

[0032] (1) Chlorination reaction: in parts by weight, adding 400 kg of p-toluoylbenzoic acid into 1000 L of oleum and 500 L of concentrated sulfuric acid with an acidity of 105% is dehydrated at 120° C., and is incubated for 1.3 hours to generate 2-methyl Anthraquinone; then, under the action of 3 parts of sulfur, chlorine gas was introduced at a temperature of 0°C and a pressure of 0.03 MPa to react, and after heat preservation for 1.2 hours, it was washed and dried to obtain 1-chloro-2-methylanthraquinone;

[0033](2) Condensation reaction: In parts by weight, add 500 kg of 1-chloro-2-methylanthraquinone obtained in step (1) into the condensation pot, heat to 104°C, dehydrate for 1.2 hours, then add o-dichlorobenzene 40kg, 80kg of N-methylpyrrolidone, heated to 180°C to melt all the materials; slowly add 200kg of copper powder under stirring, then slowly raise the temperature to 180°C, control the pressure at 0.2MPa, keep warm for 11.5 hours, add 1000L of Chlorobenzene, cool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com