SEBS/PP (styrene-ethylene-butadiene-styrene/polypropylene) alloy melt-grafted maleic anhydride graft copolymer and preparation method thereof

A technology of grafting maleic anhydride and graft copolymers, which is applied in the field of SEBS/PP alloy melt-grafted maleic anhydride graft copolymers and its preparation, can solve the problems of high SEBS rubber content, poor processing fluidity, and high viscosity , to achieve the effect of improving compatibility, improving fluidity and expanding the field of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

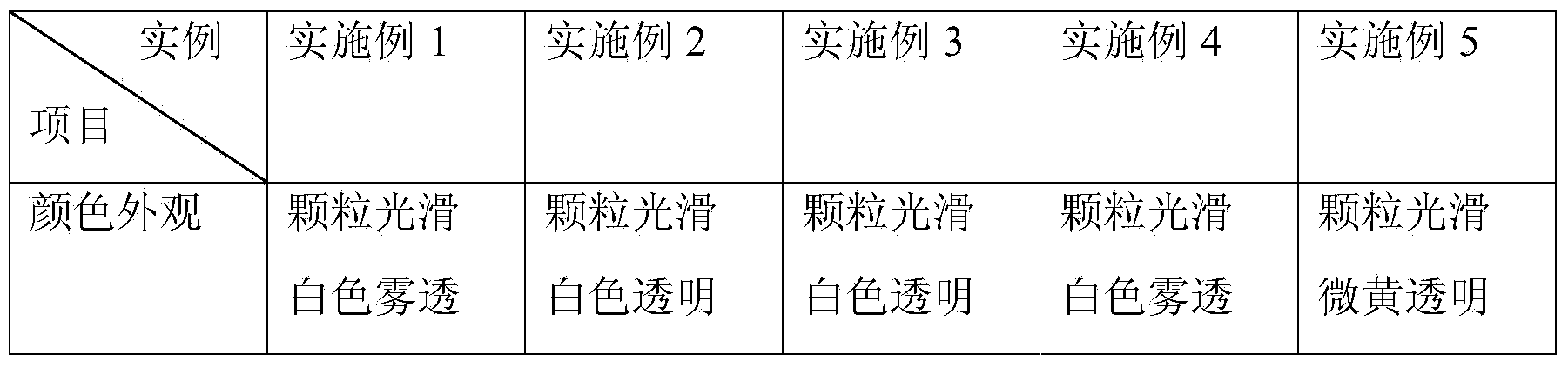

Examples

Embodiment 1

[0024] Weigh the following components by weight: 60 parts of SEBS (Baling Petrochemical, YH503), 40 parts of polypropylene PP (Ningbo Yongxing, 045), 2 parts of maleic anhydride monomer, 1 part of styrene monomer, initiator Dissolve and dilute 0.2 parts of dicumyl peroxide (DCP) with 1.5 parts of diluent acetone, and 0.5 parts of lubricant erucamide. Mix the above-mentioned raw and auxiliary materials in a low-speed mixer for 15 minutes, and then add them to the twin-screw extruder. 200°C, 190°C, 190°C, 180°C, 180°C, 170°C, the machine head is 170°C, the mixed material is melted and plasticized, kneaded and mixed, machine head extruded, water ring pelletized, cooled, dehydrated, drum Air-dried to obtain the product.

Embodiment 2

[0026] Take the following components by weight: 80 parts of SEBS (Taiwan Rubber, 6152), 20 parts of polypropylene PP (Dushanzi Petrochemical, K8003), 3 parts of maleic anhydride monomer, 3 parts of styrene monomer, and the initiator is 0.3 part of 2,5-dimethyl-2,5 bis(tert-butyl peroxy)hexane was dissolved and diluted with 2 parts of diluent acetone, and 0.3 part of lubricant ethylene bisstearamide. Mix the above-mentioned raw and auxiliary materials in a low-speed mixer for 15 minutes, and then add them to the twin-screw extruder. 190°C, 190°C, 180°C, 180°C, 180°C, 170°C, the machine head is 170°C, the mixed material is melted and plasticized, kneaded and mixed, extruded by the machine head, water ring pelletized, cooled, dehydrated, drummed Air-dried to obtain the product.

Embodiment 3

[0028] Weigh the following components in parts by weight: 30 parts of SEBS (Baling Petrochemical, YH503), 45 parts of SEBS (Baling Petrochemical, YH501), 25 parts of polypropylene PP (Zhenhai Petrochemical, F3-045), maleic anhydride mono 2.5 parts of styrene monomer, 1.5 parts of styrene monomer, 0.15 parts of 2,5-dimethyl-2,5 bis(tert-butyl peroxy)hexane as initiator, dissolved and diluted with 1.5 parts of ethanol as diluent, ethylene as lubricant 0.4 parts of bis stearylamide. Mix the above-mentioned raw and auxiliary materials in a low-speed mixer for 15 minutes, and then add them to the twin-screw extruder. 195°C, 195°C, 190°C, 180°C, 180°C, 170°C, the machine head is 170°C, the mixed material is melted and plasticized, kneaded and mixed, extruded by the machine head, water ring pelletized, cooled, dehydrated, drummed Air-dried to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com