Lithographic original plate and printing method thereof

A technology for lithographic printing plates and original plates, applied in the field of lithographic printing plate original plates and their printing, can solve problems such as failure to achieve environmental protection, and achieve the effects of good on-machine developability, improved printing durability, and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation of plate base: A1050 rolled aluminum plate with a purity of 99.5% and a thickness of 0.3 mm was etched in a 5% aqueous solution of sodium hydroxide at 70°C for 20 seconds, rinsed with running water, and immediately neutralized with a 1% aqueous solution of nitric acid; Then in 1% hydrochloric acid aqueous solution, at 40°C, use sine wave alternating current at 50A / dm 2 Electrolytic coarsening at the current density for 16 seconds; then neutralize with 5% sodium hydroxide aqueous solution for 10 seconds at 40°C, and wash with water; finally, at 30°C, use 20% sulfuric acid aqueous solution at 15A / dm 2 current density, anodize for 20 seconds, wash with water; use 5% sodium silicate aqueous solution for 18 seconds at 80°C for sealing treatment, wash with water, and dry; Weight 3.0g / dm 2 .

[0038] Photosensitive layer coating: Extrude and coat the following photosensitive liquid on the above-mentioned hydrophilized plate base, and then dry at 100°C for 60 seco...

Embodiment 2

[0053] Prepare the base and photosensitive layer in the same way as above. Photosensitive liquid with the following components:

[0054] Polymer with structure A2 2.932

[0055] Hydroxypropyl cellulose 0.180

[0056] Polyurethane Acrylic Prepolymer 0.72

[0057] Pentaerythritol triacrylate 0.684

[0058] Hexaarylbiimidazole 0.180

[0059] Sulfonium hexafluorophosphate 0.72

[0060] Infrared absorbing dye D1 0.036

[0061] Leuco Crystal Violet 0.180

[0062] BYK-333 0.004

[0063] 1-methoxy-2-propanol 34.36

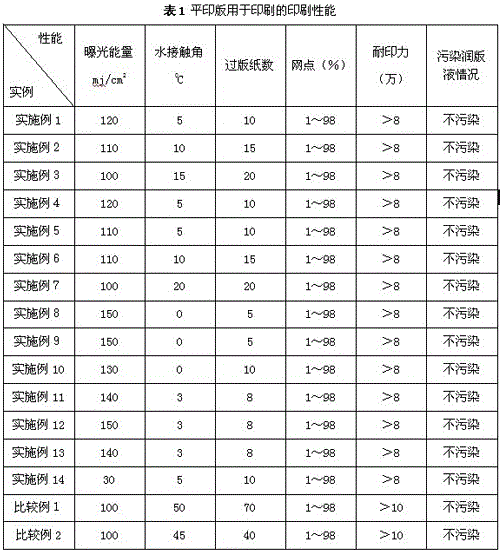

[0064] The plate material obtained in this way is used to measure the water drop contact angle by the method described above, and it is 110mJ / cm2 on the Kodak Quansheng thermosensitive CTP plate-making machine. 2 The energy is exposed; then, the plate is loaded onto the printing press for printing, and its properties are listed in Table 1 below.

Embodiment 3

[0066] Prepare the base and photosensitive layer in the same way as above. Photosensitive liquid with the following components:

[0067] Polymer with structure A3 2.932

[0068] Hydroxypropyl cellulose 0.180

[0069] Polyurethane Acrylic Prepolymer 0.72

[0070] Pentaerythritol triacrylate 0.684

[0071] Hexaarylbiimidazole 0.180

[0072] Sulfonium hexafluorophosphate 0.72

[0073] Infrared absorbing dye D1 0.036

[0074] Leuco Crystal Violet 0.180

[0075] BYK-333 0.004

[0076] 1-methoxy-2-propanol 34.36

[0077] The plate material obtained in this way is used to measure the contact angle of water droplets by the method described above, and the contact angle is measured at 100mJ / cm2 on the Kodak Quansheng thermosensitive CTP plate-making machine. 2 The energy is exposed; then, the plate is loaded onto the printing press for printing, and its properties are listed in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com