High-voltage electrolyte for lithium ion battery and application of high-voltage electrolyte

A lithium-ion battery and electrolyte technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of low reversible lithium intercalation, capacity fading, hindering the normal deintercalation of lithium ions, etc., and improve the interface film formation characteristics. , Improve the effect of electrolyte decomposition and high-pressure cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In a glove box filled with argon (moisture 2 CF=CHOCFHCF 2 , 1,3-propene sultone, the addition amount accounted for 16% and 4% of the total mass of the electrolyte respectively. Finally, lithium hexafluorophosphate was slowly added to the mixed solution to control its concentration to 1.2M, and the lithium ion battery electrolyte was obtained after stirring evenly, marked as A. At the same time, with 1.2M LiFP 6 It is a lithium salt, the solvent is ethyl methyl carbonate and ethylene carbonate, and the traditional lithium ion electrolyte with a ratio of 7:3 is marked as B.

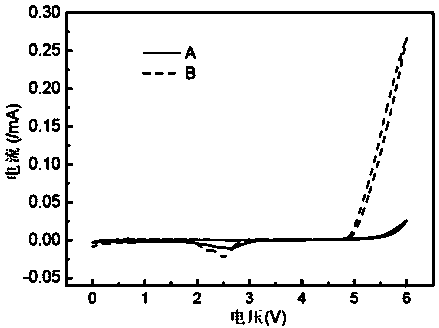

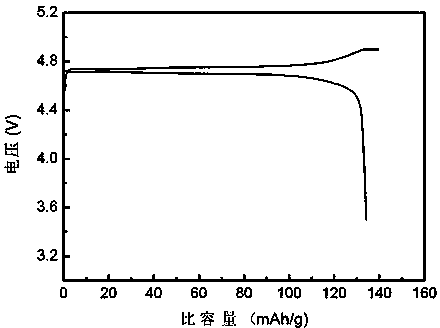

[0025] The above-mentioned configuration of lithium-ion electrolyte was respectively injected into a button battery with a positive electrode of lithium nickel manganese oxide and a negative electrode of lithium metal, and a 1C charge-discharge cycle was performed within the voltage range of 3.5~4.9V. The lithium-ion electrolytic solution prepared in this example The cyclic voltammetry curves of s...

Embodiment 2

[0027] In an argon-filled glove box (moisture 2 CF=CHOCFHCF 2 , fluoroethylene carbonate, and 1,3-propene sultone, the addition amounts accounted for 15%, 22%, and 3% of the total mass, respectively. Finally, lithium hexafluorophosphate was slowly added to the mixed solution to control its concentration to 1 M, and the lithium ion battery electrolyte was obtained after stirring evenly.

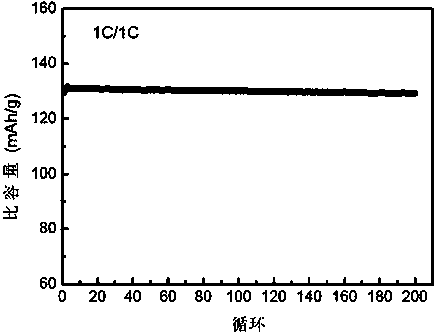

[0028] Inject the configured lithium-ion battery electrolyte into a button battery with a positive electrode of lithium nickel manganese oxide and a negative electrode of lithium metal, and perform a 1C charge-discharge cycle within the voltage range of 3.5~4.9V. The battery charge-discharge cycle is 200 times, and the capacity is retained. The rate reached 98%.

Embodiment 3

[0030]In an argon-filled glove box (moisture 2 CF=CHOCFHCF 2 , fluoroethylene carbonate, 1,3-propene sultone, and vinylene carbonate, the addition amounts accounted for 15%, 23%, 4%, and 1% of the total mass, respectively. Finally, lithium hexafluorophosphate was slowly added to the mixed solution to control its concentration to 1.2M, and the lithium ion battery electrolyte was obtained after stirring evenly.

[0031] Inject the configured lithium-ion electrolyte into a button battery with a positive electrode of lithium nickel manganese oxide and a negative electrode of lithium metal, and perform a 1C charge-discharge cycle within the voltage range of 3.5~4.9V. The battery charge-discharge cycle is 200 times, and the capacity retention rate Reached 97%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com