A highly selective oxygen-containing coal bed gas catalytic deoxygenation catalyst and preparation method thereof

A catalytic deoxygenation catalyst, high selectivity technology, applied in gas fuel, petroleum industry, fuel and other directions, can solve the problems of increasing refrigeration power consumption, increasing safety hazards, etc., to eliminate safety hazards, high catalytic activity and stability, high The effect of complete combustion of methane on selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

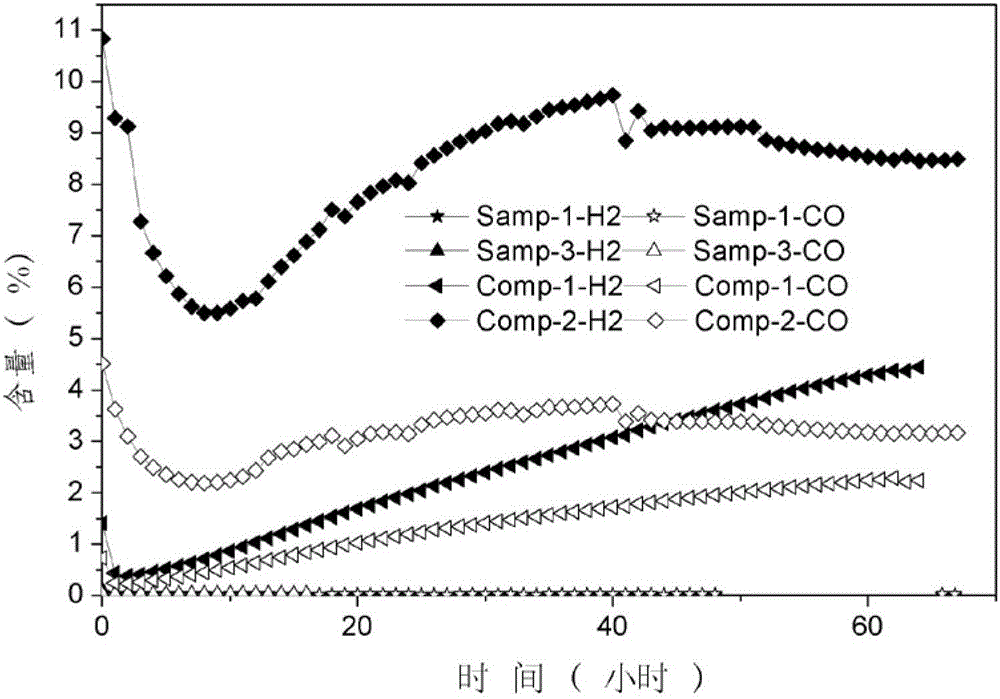

Image

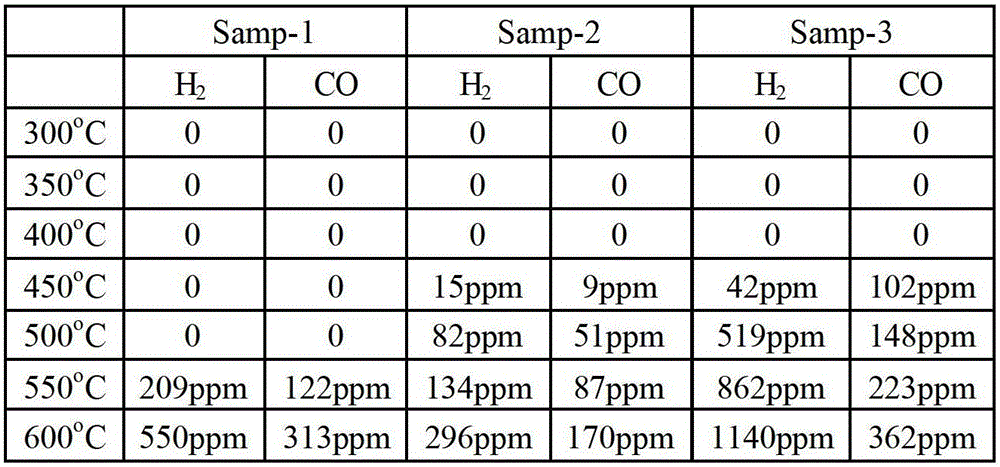

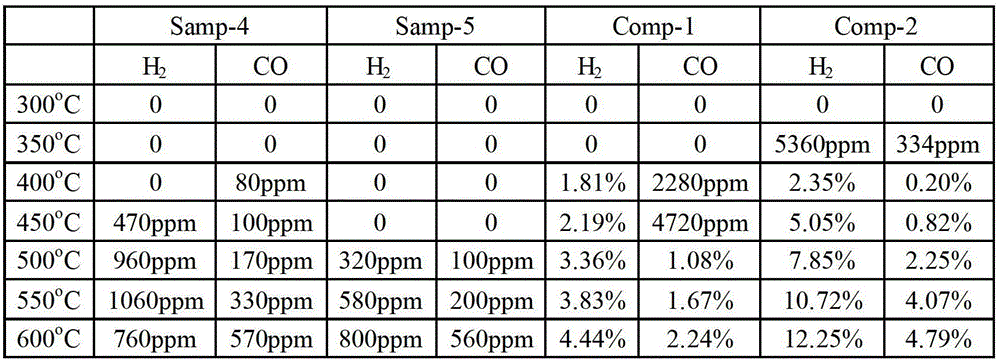

Examples

Embodiment 1

[0037] Weigh 144.1g of urea, dissolve it in 1000ml of deionized water; weigh 37.92g of SnCl 2 , dissolve it in 500ml deionized water; then, transfer all the aqueous solutions of the two into a beaker, stir, and dissolve completely; add 500ml of water, and transfer it to a three-necked flask; then place it in an oil bath, while Heating while stirring, when the color of the solution becomes turbid, stir at this temperature for another 2 hours; then, cool and filter, and wash with Cl - , then dried at 120°C overnight; baked at 650°C for 2 hours to obtain SnO 2 Carrier 30g.

[0038] After fully grinding and calcination at 650 °C for 2 h 2 The carrier powder is passed through a 200-mesh sieve; compressed into tablets at 20 MPa; pulverized, sieved, and 12-20-mesh granules are taken for later use.

[0039] Prepare 2M Ce(NH 4 ) 2 (NO 3 ) 6 and 2M Zr(NO 3 ) 4 aqueous solution; then, weigh 4g12-20 mesh SnO 2 Particles, measure their water absorption; measure 2.5ml of 2M Ce(NO ...

Embodiment 2

[0042] Using the same method, the catalyst sample 1%Pd / 19.8%CeO 2 -ZrO 2 (Ce:Zr=4:1) / 79.2%TiO 2 , the sample code is Samp-2.

Embodiment 3

[0044] Weigh Ce(NO 3 ) 3 .6H 2 O and Zr(NO 3 ) 4 .5H 2 O each 104.2g and 25.76g, it is dissolved in 3000ml deionized water, then add 216.22g of urea; it is placed in an oil bath, heated while stirring, when the color of the solution becomes turbid, again at this temperature Stir for 2 hours; after aging for another 2 hours, filter while washing; finally, wash with isopropanol to remove water; dry at 120°C overnight, and roast at 650°C for 2 hours to obtain a Ce-Zr ratio of 4:1 Ce-Zr composite oxide;

[0045] Get the SnO that adopts the same method that embodiment 1 makes 2 Sample 20g, uniformly disperse it in 14ml HNO with pH value of 1.2 3 solution and 16ml deionized water, adopt ball milling method ball milling for 24 hours, make coated ball milling slurry;

[0046] Immerse the 8×8×10mm cordierite honeycomb ceramics in the ball mill slurry prepared above, take it out after 10 minutes, remove the excess sol in the channel with air flow, dry it in a vacuum oven at 50°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com