Drying method of pole pieces of lithium-ion secondary battery

A drying method and secondary battery technology, applied in battery electrodes, dryers for static materials, drying of solid materials, etc., can solve the problems of low gram capacity, poor cycle performance, large self-discharge, etc., and achieve the effect of improving battery performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

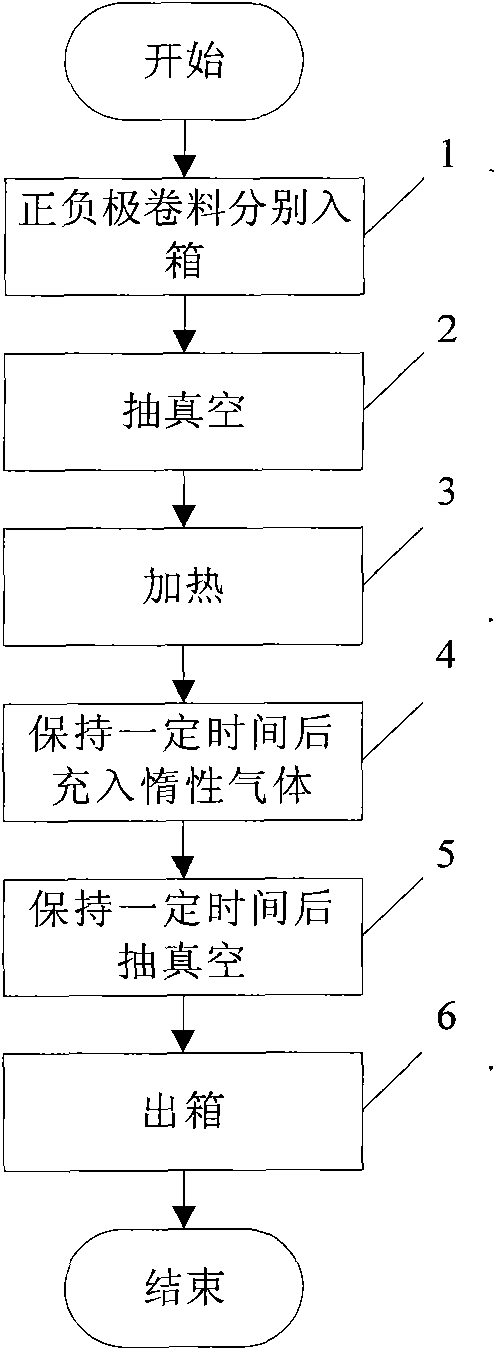

[0024] figure 1 It is a flow chart of the drying method of the pole piece of the lithium ion secondary battery according to the first embodiment of the present invention. Such as figure 1 Described, this drying method comprises the following steps:

[0025] Step 1. Put the positive and negative electrode coils into the box separately

[0026] In this step, put the coiled material into the tray in the drying box, and the tray should be clean. The purpose of this step is to avoid mixed contact of positive and negative materials and cross-contamination, so as to avoid the above-mentioned adverse effects.

[0027] Step 2. Vacuum

[0028] In this step, vacuumize the drying box to -0.1 MPa and then continue to pump for 1 to 30 minutes to close the vacuum system. The purpose of this step is to allow the coil to dry without air contact in the drying oven.

[0029] Step 3, heating

[0030] In this step, the heater is used to heat the drying box, wherein the heating temperature is...

no. 2 example

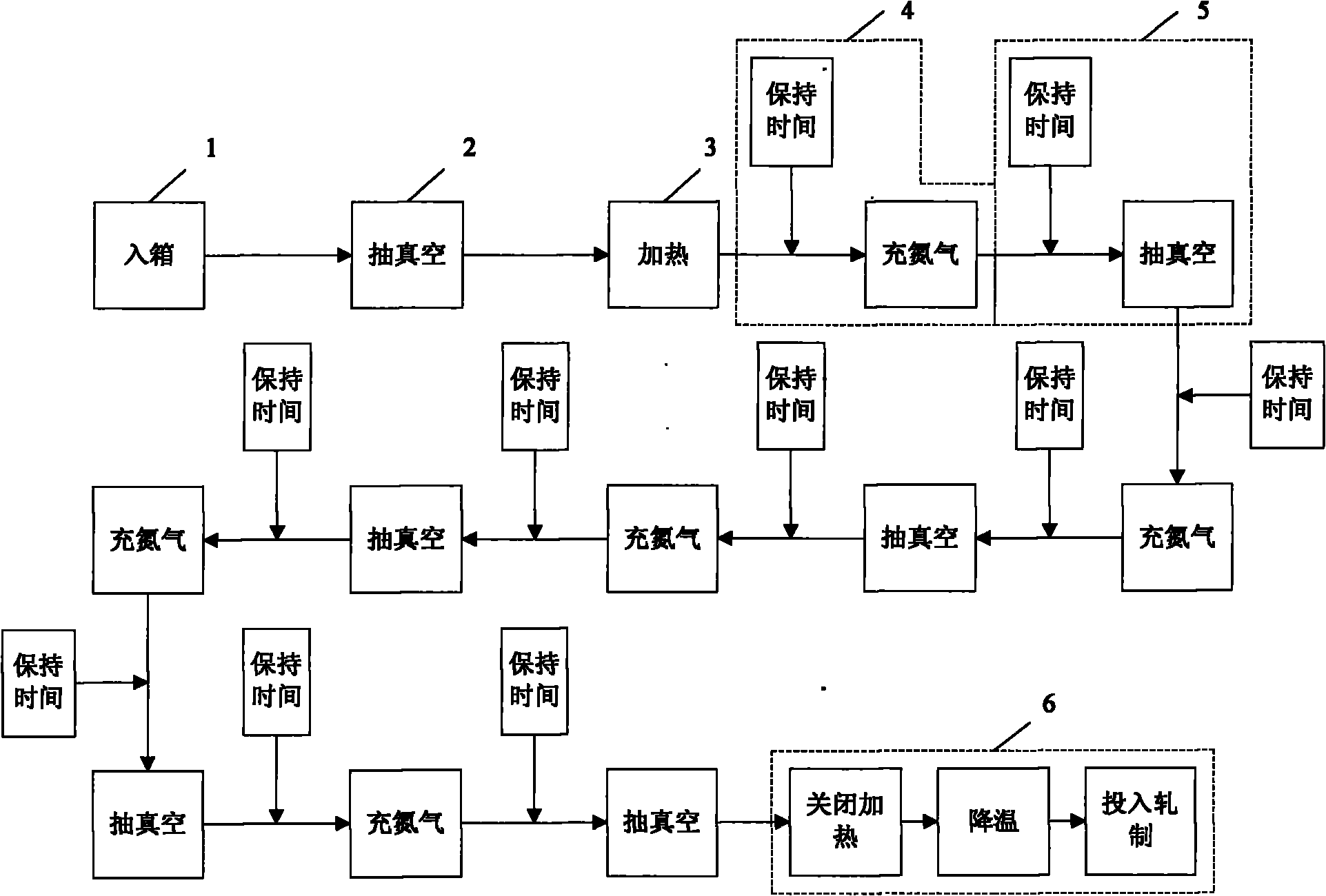

[0039] In order to further ensure that the moisture in the coil material is completely discharged, this embodiment repeats the cycle of ventilation for 5 to 20 times on the basis of the first embodiment before turning off the heater. The ventilation includes: filling inert after a certain period of time Gas (step 4) and vacuum after a certain time (step 5).

[0040] figure 2 is a schematic flow chart of a drying method for lithium-ion secondary battery pole pieces according to the second embodiment of the present invention. exist figure 2 , cycle and ventilate 5 times, that is, repeat "holding time" → "nitrogen filling" → "holding time" → "vacuumize" 5 times.

[0041] Below, the test data will be used to illustrate the battery performance comparison of different drying times.

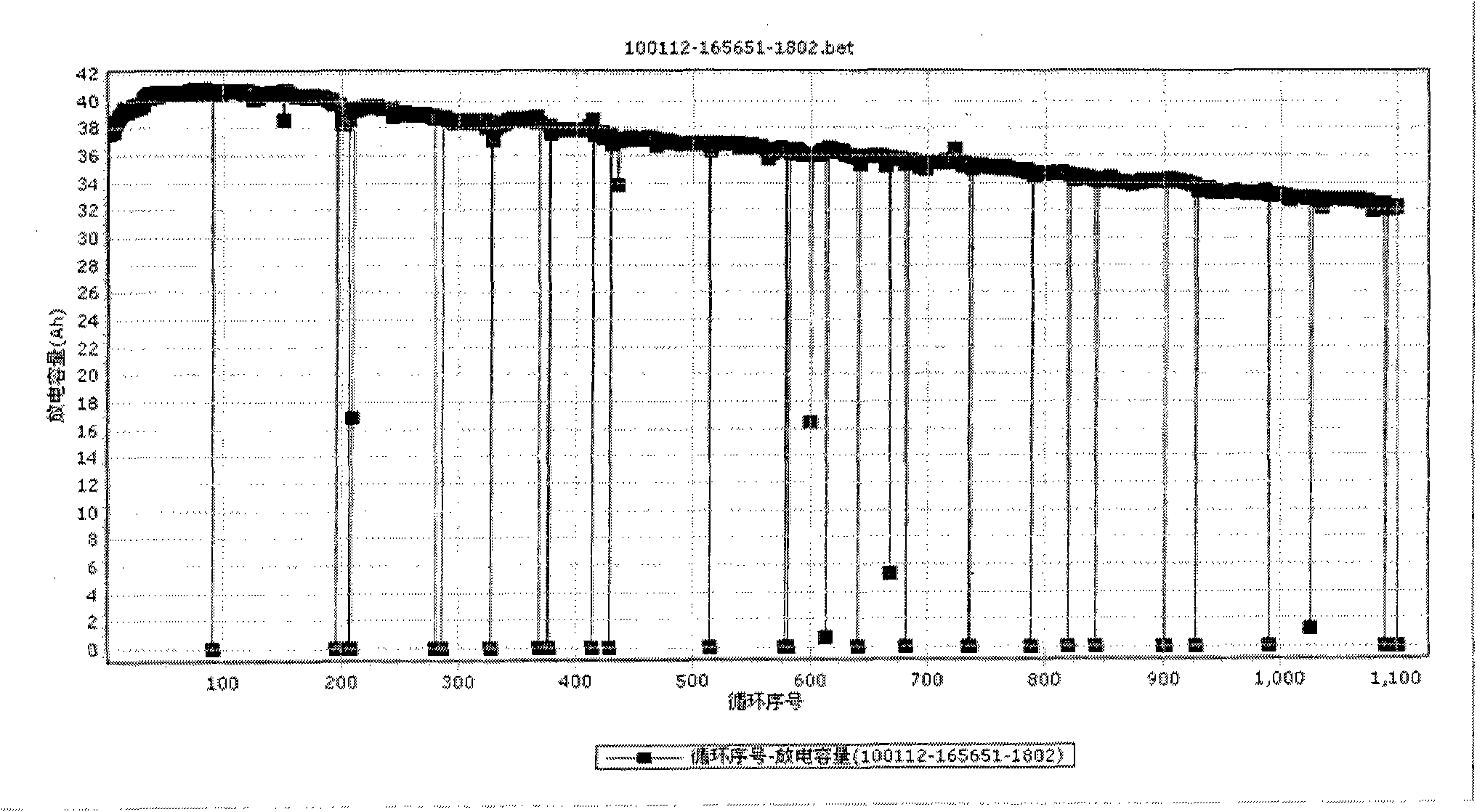

[0042] image 3 It is a graph showing the test results of Scheme 1. The process flow of Scheme 1 is: powder baking→slurry preparation→coating→rolling→slicing→slice selection→lamination→assembly→we...

no. 3 example

[0046] This embodiment provides a pole piece manufacturing method for a lithium-ion secondary battery, which is characterized in that the positive pole piece and the negative pole piece are manufactured separately, that is, the entire manufacturing process of the positive pole piece manufacturing process and the negative pole piece are implemented separately. Through this pole piece manufacturing method, the moisture in the coil material can be fully discharged, the performance of the battery can be improved to the greatest extent, and the potential safety hazard caused by battery swelling can be eliminated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com