A single crystal furnace online doping device

A single crystal furnace and furnace cover technology, which is applied in the directions of single crystal growth, diffusion/doping, crystal growth, etc., can solve the problem of increasing contact time between doping elements and molten silicon, unable to do online real-time doping, and controllable doping process Poor performance and other problems, to achieve the effect of ensuring sufficient contact and contact time, no loss of doping substances, and improving the doping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

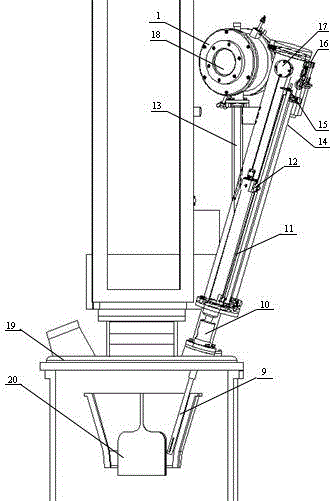

[0020] refer to Figure 1~2 , The composition of the embodiment includes a silo mechanism, a conveying mechanism and a control mechanism connected to each other, and the silo mechanism and the conveying mechanism perform doping operations according to the instructions of the control mechanism.

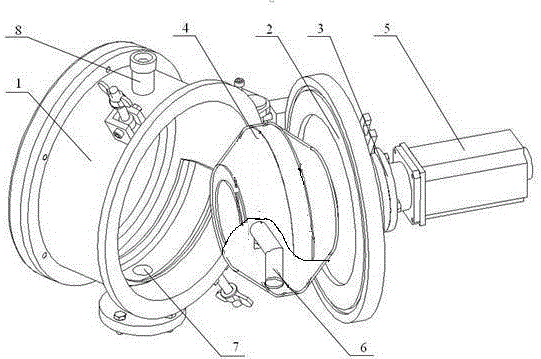

[0021] Among them, the silo mechanism includes the silo shell 1, the silo door 2, the silo sealing mechanism 3, the silo 4, the silo motor 5, the U-shaped discharge pipe 6, the collecting funnel 7, the argon gas charging port 8, the falling Material deceleration pipe 13 and observation window 18. The inside of the silo shell 1 is provided with a freely rotatable silo 4 and a U-shaped discharge pipe 6 connected with the silo 4. The lower part of the silo shell 1 is provided with a collecting funnel 7, and the lower part of the collecting funnel 7 is connected with the falling materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com