Method for brazing metal ceramic composite coating on titanium alloy surface in vacuum

A metal-ceramic composite and titanium alloy technology, which is applied in the coating process and coating of metal materials, can solve the problems of low bonding strength, low coating thickness, and high porosity of the coating, and achieve smooth and defect-free surfaces. The effect of stability and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

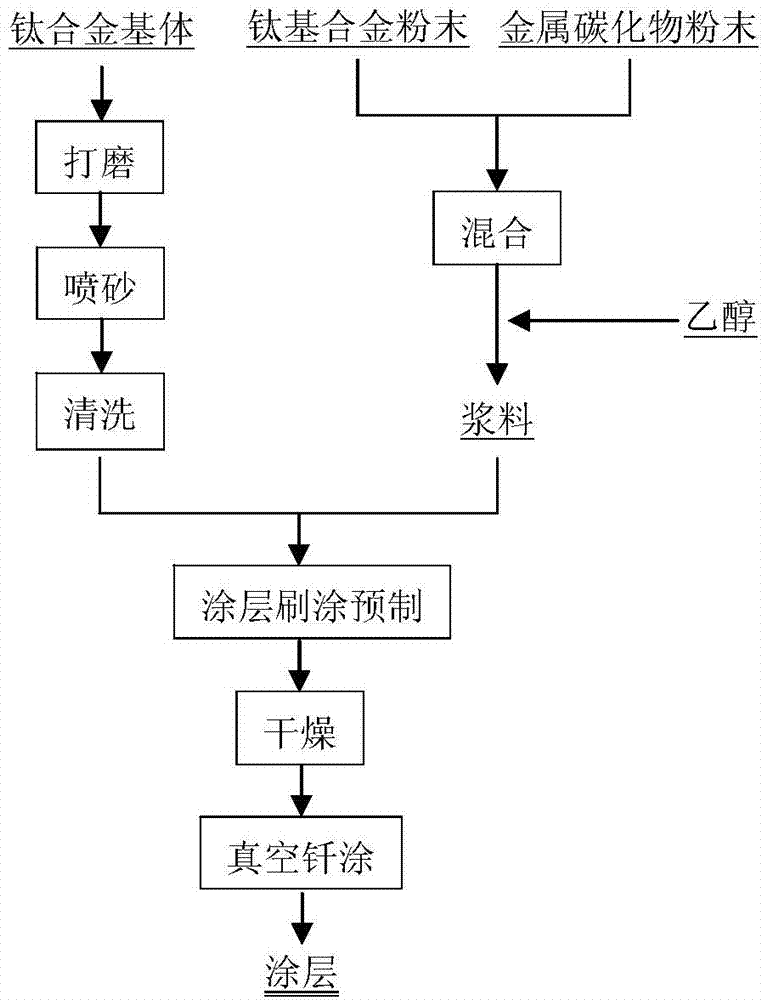

[0018] A method of vacuum brazing metal-ceramic composite coating on the surface of a titanium alloy of this test is carried out in the following steps:

[0019] (1) Surface pretreatment of titanium alloy substrate: Grind the surface of TC4 titanium alloy substrate with sandpaper, then sandblast the surface of the substrate to increase the roughness (quartz sand, particle size 140-260 mesh), and then use acetone, Ultrasonic cleaning was performed with ethanol and deionized water, and then dried in a drying oven at a constant temperature of 50°C for 10 min.

[0020] (2) Powder pretreatment: TiC powder with a particle size of 5 μm and Ti-Zr-Cu-Ni powder with a particle size of 45 μm (the mass ratio of each element is 48%Ti, 27Zr, 18%Cu, 7%Ni) on the planet Mix in a ball mill at a speed of 300r / min for 2h, and the volume fraction of TiC in the ball mill mixture is 50%. Then add ethanol to the mixed powder to prepare a slurry, and then pre-set the slurry evenly and flatly on the ...

Embodiment 2

[0023] A method of vacuum brazing metal-ceramic composite coating on the surface of a titanium alloy of this test is carried out in the following steps:

[0024] (1) Surface pretreatment of titanium alloy substrate: Grind the surface of the TA5 titanium alloy substrate with sandpaper, then sandblast the surface of the substrate to increase the roughness (quartz sand, particle size 140-260 mesh), and then use acetone, Ultrasonic cleaning was performed with ethanol and deionized water to remove residual pollutants, and then dried in a drying oven at a constant temperature of 50°C for 10 minutes.

[0025] (2) Powder pretreatment: WC powder with a particle size of 1 μm and Ti-Zr-Be powder with a particle size of 15 μm (wherein the mass ratio of each element is 46% Ti, 49% Zr, 7% Be) in a planetary ball mill Mix at a speed of 240r / min for 4h, and the volume fraction of WC in the ball-milled mixture is 40%. Add ethanol to the mixed powder to make a slurry, and place the slurry even...

Embodiment 3

[0028] A method of vacuum brazing metal-ceramic composite coating on the surface of a titanium alloy of this test is carried out in the following steps:

[0029] (1) Surface pretreatment of titanium alloy substrate: Grind the surface of TB2 titanium alloy with sandpaper, then sandblast the surface of the substrate to increase the roughness (quartz sand, particle size 140-260 mesh), and then use acetone and ethanol in sequence Ultrasonic cleaning with deionized water was performed to remove residual pollutants, and then dried in a drying oven at a constant temperature of 50°C for 10 minutes.

[0030] (2) Powder pretreatment: ZrC powder with a particle size of 20 μm and Ti-Ni-Nb powder with a particle size of 45 μm (where the mass ratio of each element is 42% Ti, 38% Ni, 20% Nb) was mixed in a horizontal ball mill to Mix at a speed of 150 r / min for 10 h, and the volume fraction of ZrC in the ball-milled mixture is 20%. Add ethanol to the mixed powder to make a slurry, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com