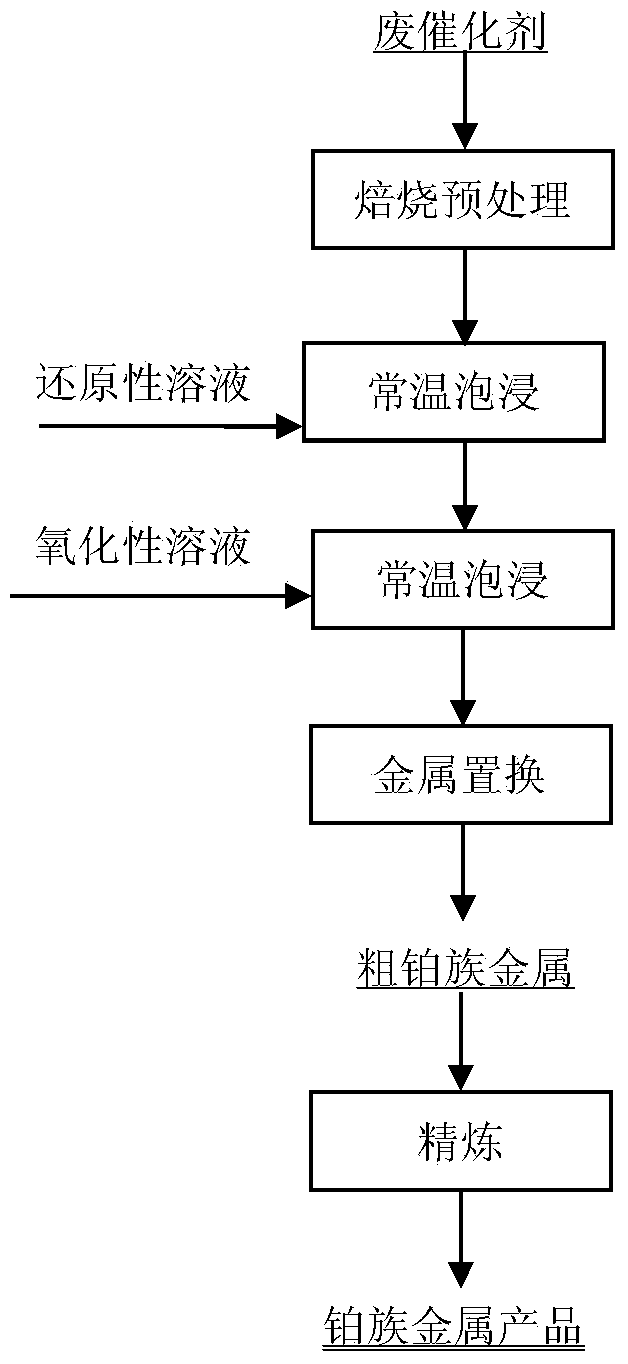

Method for recovering platinum metal from waste catalyst

A platinum group metal and waste catalyst technology, applied in the direction of improving process efficiency, can solve the problems of large acid consumption, high viscosity and high concentration of aluminum sulfate solution, and achieve simplified process operation, low aluminum salt content, and easy filtration and separation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1, the waste palladium / alumina catalyst was roasted at 600° C. for 1.5 h, after cooling, 100 kg of material (containing palladium 2240 g / t) was placed in a soaking tank covered with a filter cloth at the bottom, and the mass concentration was 2% Soak in the hydrazine hydrate solution for 3 hours, release the solution, then add 3mol / L hydrochloric acid, 30g / L sodium chlorate mixed solution and soak for 24 hours, release the palladium-containing solution; continue to add 3mol / L hydrochloric acid, 30g / L chlorine Immerse in the mixed solution of sodium bicarbonate for 24 hours to release the palladium-containing solution; combine the soaking solutions twice, adjust the acidity of the solution to 3mol / L with hydrochloric acid, add aluminum block for replacement, and obtain crude palladium, obtain 219.82g of palladium sponge by dissolving and refining, and recover Yield 98.13%, purity 99.95%

Embodiment 2

[0018] Example 2, the spent palladium / alumina catalyst is roasted at 600°C for 2h, after cooling, take 100kg of material (containing palladium 2240g / t) and place it in a soaking tank with a filter cloth at the bottom, and add a mass concentration of 2% Soak in hydrazine hydrate solution for 3 hours, release the solution, then add 4mol / L hydrochloric acid, 30g / L sodium chlorate mixed solution, soak for 24 hours, release palladium-containing solution; continue to add 4mol / L hydrochloric acid, 30g / L chloric acid Soak in the sodium mixed solution for 12 hours to release the palladium-containing solution; continue to add 3mol / L hydrochloric acid and 20g / L sodium chlorate mixed solution to soak for 12 hours to release the palladium-containing solution; combine the soaking solutions for 3 times, and adjust the acidity of the solution with hydrochloric acid 3mol / L, add aluminum block to replace, obtain crude platinum group metals, obtain 221.3g of sponge palladium by dissolving and ref...

Embodiment 3

[0019] Example 3, the waste platinum rhenium / alumina catalyst was roasted at 600°C for 2 hours, after cooling, 50kg of material (containing about 0.44% platinum) was placed in a immersion tank covered with filter cloth at the bottom, and the mass concentration was 2% Soak in the sodium formate solution for 2 hours, release the solution, then add 6mol / L hydrochloric acid, 20g / L sodium chlorate mixed solution, soak for 12 hours, release the platinum-containing solution; continue to add 4mol / L hydrochloric acid, 20g / L chloric acid Soak in the sodium mixed solution for 12 hours to release the platinum-containing solution; continue to add 3mol / L hydrochloric acid and 20g / L sodium chlorate mixed solution to soak for 12 hours to release the platinum-containing solution; combine the soaking solutions for 3 times, and adjust the acidity of the solution with hydrochloric acid 3 mol / L, add aluminum blocks to replace, obtain crude platinum group metals, and obtain 217g sponge platinum by d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com