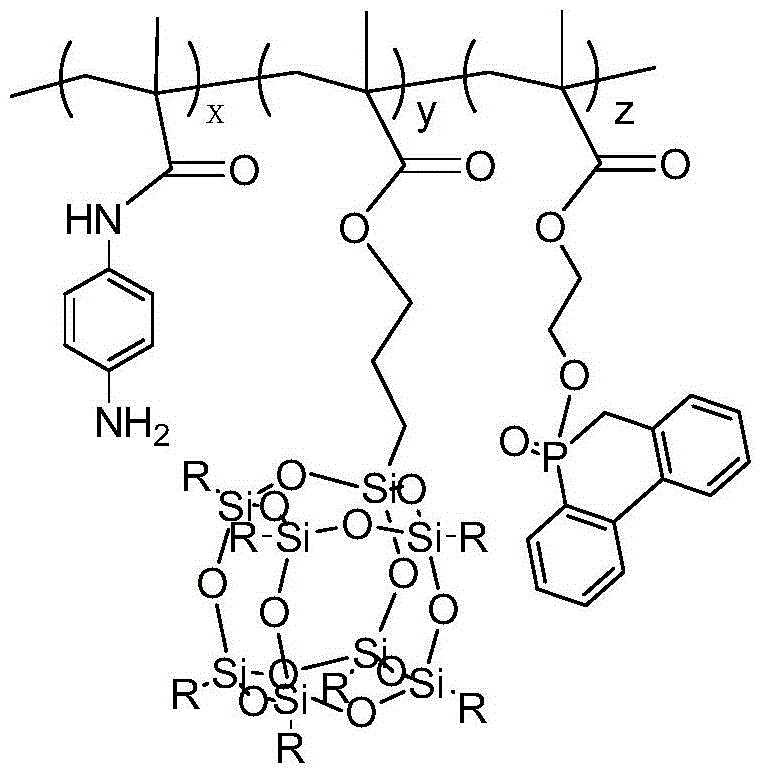

A kind of phosphorus-containing silicon reactive macromolecular flame retardant and its preparation method and application

A flame retardant and reactive technology, applied in the field of phosphorus-containing silicon reactive macromolecular flame retardants and their preparation, can solve problems such as poor compatibility and affect the mechanical properties of materials, and achieve increased stability, high yield, The effect of eliminating the influence of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

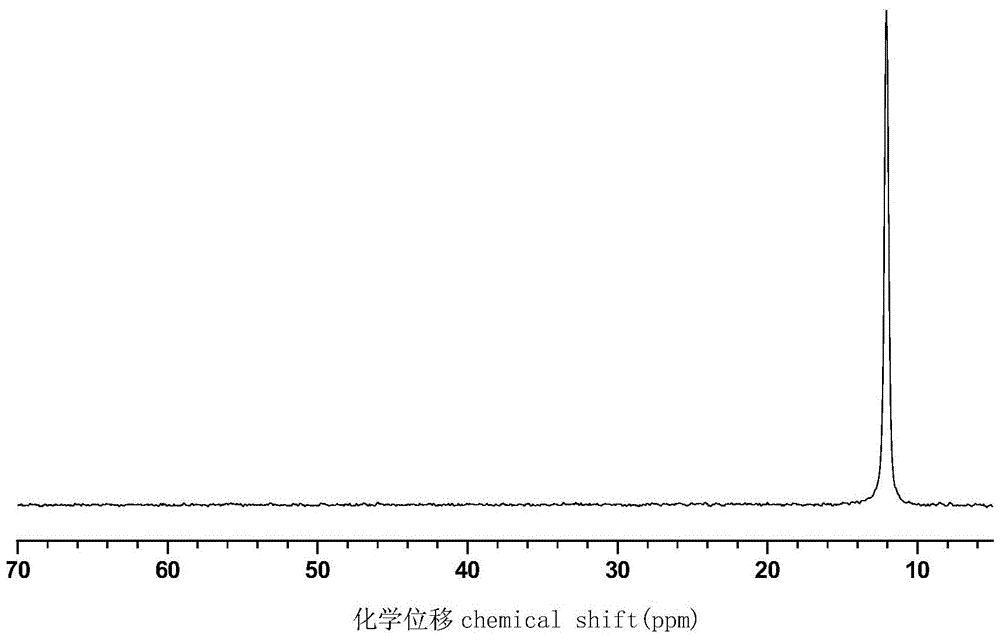

Image

Examples

Embodiment 1

[0032] (1) Synthesis of 4-methacrylamidoaniline

[0033] Dissolve 21.6g of p-phenylenediamine and 20.2g of triethylamine in 200mL of dichloromethane, slowly add 20.9g of methacryloyl chloride dropwise under stirring at 5°C, and continue the reaction for 20h after the dropwise addition; the reaction is over Afterwards, triethylamine hydrochloride was removed by filtration, and washed several times with 3% NaOH solution, distilled water, and saturated NaCl aqueous solution successively. Anhydrous MgSO for organic layer 4 Without drying, 4-methacrylamidoaniline was obtained by rotary evaporation and drying.

[0034] (2) Synthesis of phosphorus-containing monomers

[0035] Dissolve 21.6g of DOPO, 10.1g of triethylamine and 15.4g of carbon tetrachloride in 200mL of dichloromethane, slowly add 13.0g of hydroxyethyl methacrylate under stirring conditions, and react at 20°C for 8h after the dropwise addition is completed, then Suction filtration under reduced pressure to remove tri...

Embodiment 2~5

[0041] Step (1) and step (2) are the same as embodiment 1. Change the ratio of the amount of material of 4-methacrylamidoaniline, MAiBuPOSS and phosphorus-containing monomer in the step (3) (recorded as x: y: z) and step (4) epoxy resin and phosphorus-containing The mass ratio of silicon-reactive macromolecular flame retardants can obtain epoxy resins with different flame retardant properties.

[0042] Table 1

[0043] Example

[0044] Table 1 gives the results of epoxy resins with different flame retardant properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com