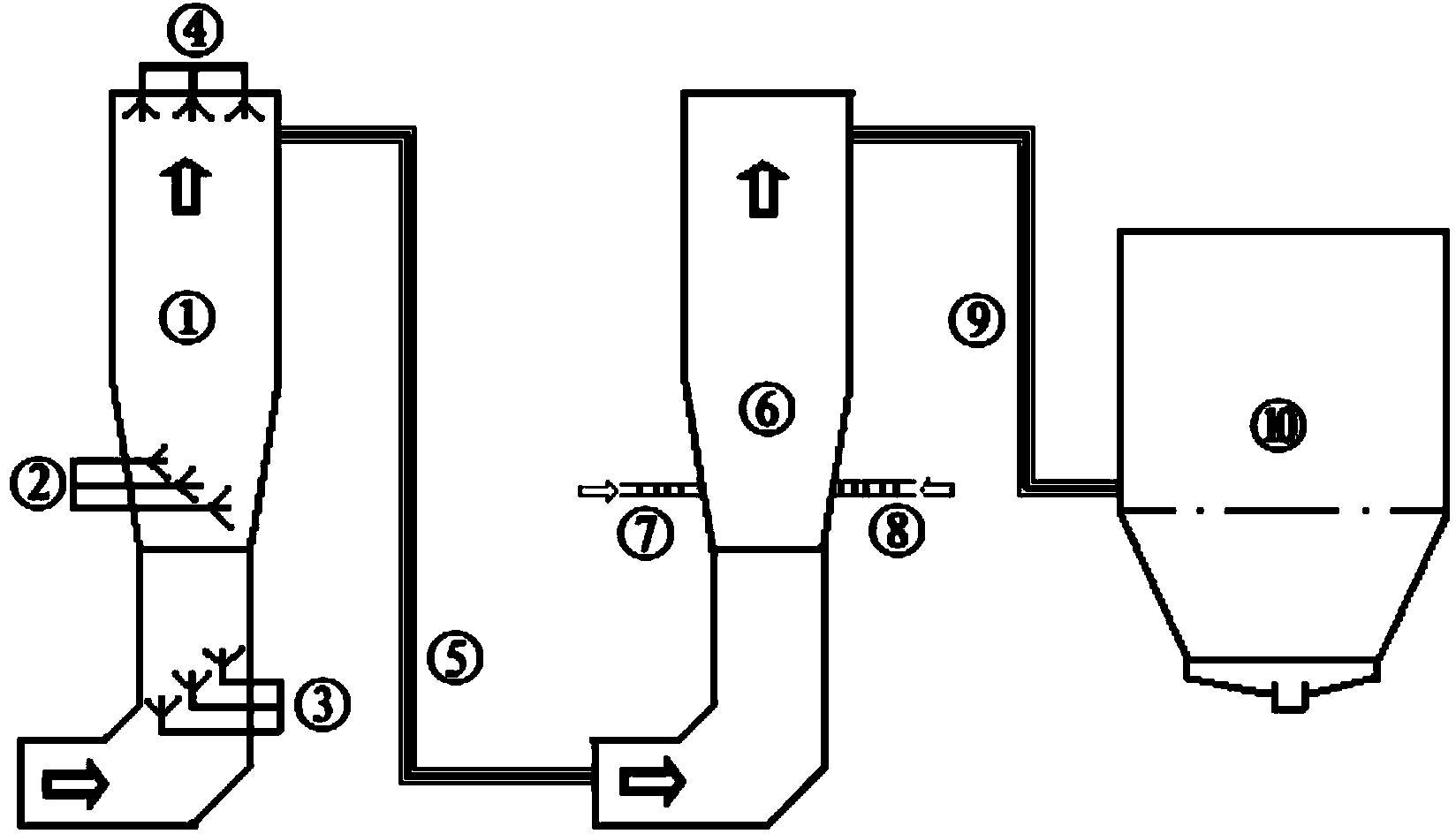

Smoke denitration method and device

A denitration and flue gas technology, applied in the field of flue gas purification, can solve the problems of increasing operating costs, large consumption of denitration oxidant absorbent, and low denitration efficiency, and achieves the effects of reducing consumption, reducing consumption and improving denitration efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The method provided by the present invention is used for the generator set in Comparative Example 1, and the circular denitrification oxidation reactor with a diameter of 7.6m and a length of 20m is set, the flue gas flow rate is 8m / s, the outlet of the denitrification oxidation reactor and the absorption reactor The inlet is connected, using 82% pure sodium chlorite (NaClO 2 ) as denitration oxidant, 85% purity Ca(OH) 2 As an absorbent, the denitrification oxidant is placed in the denitrification oxidation reactor, and the absorbent is placed in the absorption reactor.

[0065] On the basis of not changing the basic operating parameters of the system, the denitrification oxidation reactor and the absorption reactor were put into operation. When the denitrification oxidant sodium chlorite was used at 572kg / h, the NOx concentration in the flue gas at the outlet of the absorption reactor was detected to be 100mg / Nm 3 .

[0066] The calculated denitrification efficiency ...

Embodiment 2

[0068] The method provided by the present invention is used for the generator set in Comparative Example 1, and the circular denitrification oxidation reactor with a diameter of 7.6m and a length of 20m is set, the flue gas flow rate is 8m / s, the outlet of the denitrification oxidation reactor and the absorption reactor The inlet is connected, using 82% pure sodium chlorite (NaClO 2 ) as denitration oxidant, 85% purity Ca(OH) 2 as an absorbent.

[0069]On the basis of not changing the basic operating parameters of the system, the denitrification oxidation reactor and the absorption reactor were put into operation. When the consumption of sodium chlorite, the denitrification oxidant, was 715kg / h, the NOx concentration in the flue gas at the outlet of the absorption reactor was detected to be 60mg / Nm 3 .

[0070] The calculated denitrification efficiency is 81.25%. At this time, the absorbent Ca(OH) 2 The consumption is 253kg / h. Compared with the comparative example, under th...

Embodiment 3

[0076] The method provided by the present invention is used for the generator set in Comparative Example 2, and a circular denitrification oxidation reactor with a diameter of 7.6m and a length of 20m is set, the flue gas flow rate is 8m / s, the outlet of the denitrification oxidation reactor and the inlet of the absorption reactor Connected, using 32% pure hydrogen peroxide (H 2 o 2 ) as denitration oxidant, 85% purity Ca(OH) 2 As an absorbent, the denitrification oxidant is placed in the denitrification oxidation reactor, and the absorbent is placed in the absorption reactor.

[0077] On the basis of not changing the basic operating parameters of the system, the denitrification oxidation reactor and the absorption reactor were put into operation. When the denitrification oxidant hydrogen peroxide dosage was 1120kg / h, the NOx concentration in the flue gas at the outlet of the absorption reactor was detected to be 100mg / Nm 3 .

[0078] The calculated denitrification efficien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com